5A molecular sieve adsorbent, and preparation method and application thereof

A molecular sieve and adsorbent technology, applied in the field of 5A molecular sieve adsorbent, can solve the problems of difficult pollution control, difficult to deal with ammonia nitrogen sewage, sewage COD exceeding the standard, etc., and achieve the effect of high 5A molecular sieve content, high adsorption efficiency and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

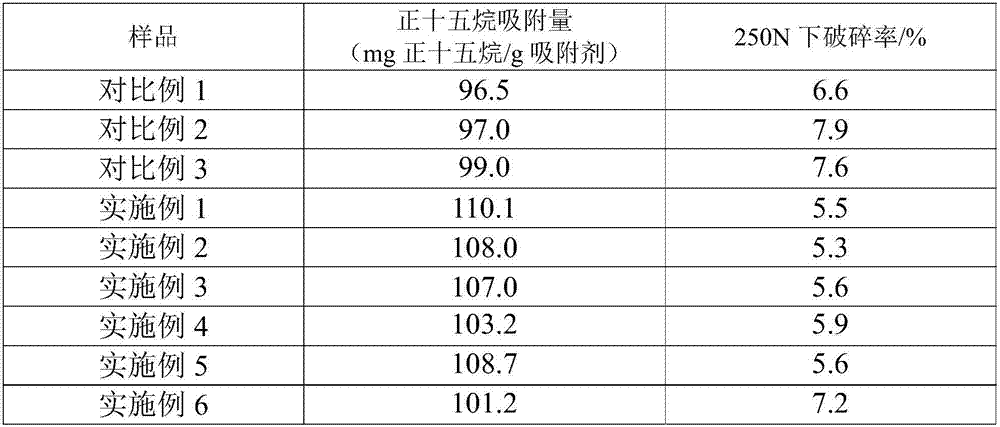

Examples

Embodiment approach

[0023] According to a preferred embodiment of the present invention, the ambient humidity of stage (3) is preferably higher than that of stage (1).

[0024] According to a more preferred embodiment of the present invention, the ambient humidity of stage (1) is 20-40% RH, the ambient humidity of stage (2) is 10-15% RH, and the ambient humidity of stage (3) is 50-90 %RH.

[0025] According to the method of the present invention, the purpose of the present invention can be realized as long as it is ensured that the pre-wetting is carried out according to the aforementioned steps before the matrix pellet is carried out to crystallization, and for the present invention, in order to further improve the positive The pentadecane adsorption capacity is preferably 15% by weight or more, preferably 18-22% by weight, after the pre-wetting of the matrix pellets after the stages (1), (2) and (3).

[0026] According to the method of the present invention, RH refers to relative humidity, spe...

Embodiment 1

[0066] (1) Get 400kg of commercially available 4A molecular sieve former powder (moisture content is 21% by weight, average grain diameter is 0.7μm, methanol adsorption capacity is 181mg / g) and kaolin 20kg (water content is 22% by weight) ), 10kg of safflower powder pore-forming agent was put into a twin-screw mixer and mixed for 3 hours, and 50kg of the mixed material was taken out, and put into a rolling ball pot (sugar-coated pot) with a diameter of 1.2m to carry out rolling ball molding to make small The operating conditions in the ball (rolling ball pot include: the speed control is 30 rpm, the water addition rate is based on the water content of the material increasing by 3-5% by weight per hour, and when the final moisture content of the material reaches 45-50% by weight, stop adding water , then keep the rotating speed of the rolling ball pot at 30-40 rpm, and continue to rotate for 3-5 hours), when the ball grows to a diameter of 0.3-1.0mm, polish it for 1-2 hours, and...

Embodiment 2

[0081] Prepare 5A molecular sieve adsorbent pellets according to the method of Example 1, the difference is that the stage (1), stage (2), and stage (3) are successively pre-wetted, and the ambient humidity of stage (1) is 40% RH, The environmental humidity of stage (2) is 15%RH, and the environmental humidity of stage (3) is 55%RH, and the moisture content of the substrate pellet after prewetting is 22% by weight, and the substrate pellet that prewets is sent into synthetic kettle In contact with sodium hydroxide aqueous solution to carry out two-stage crystallization treatment, the first stage temperature is 50 ° C, time is 3 hours, the second stage temperature is 90 ° C, time is 3 hours; the rest of the conditions are the same, and 5A molecular sieve pellets are obtained. Adsorbent (the water content of the adsorbent is 2.5% by weight, based on the dry weight of the adsorbent, the content of 5A molecular sieve is 98.5% by weight, and the diameter is 0.3-0.9mm. Related proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com