Automatic glue preparation device

An automatic glue dispensing and glue dispensing technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve the problems of large amount of impregnated glue, time-consuming and labor-intensive operation, and low equipment efficiency. Fast configuration, clear working principle and high configuration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

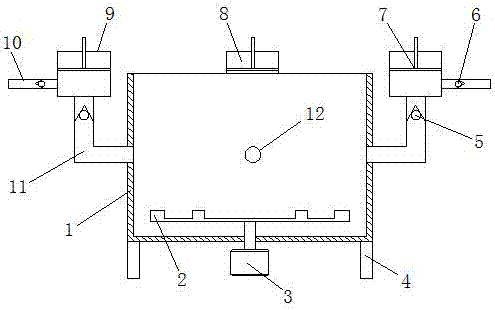

[0016] like figure 1 As shown, the automatic glue dispensing device includes a glue dispensing box 1, a foot 4 arranged at the bottom of the glue distributing box 1; a stirring motor 3 is provided at the bottom of the glue distributing box 1, and a stirring blade 2 is arranged above the stirring motor 3, The front, rear, left and right directions of the exterior of the glue dispensing box 1 are provided with a feeding assembly 8. The feeding assembly 8 consists of a feeding cylinder 9, a pushing piston 7, a feeding pipe 10, a discharging pipe 11 and a one-way valve. One end of the feed pipe 10 is connected to the raw material end, the other end of the feed pipe 10 is connected to the bottom of the feeding cylinder 9, one end of the discharge pipe 11 is connected to the bottom of the feeding cylinder 9, and the other end is connected to the batching box 1 In the same way, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com