Novel electric cigarette atomizer and tobacco tar atomizing method thereof

An electronic cigarette atomizer and oil atomization technology, which is applied in the field of e-liquid atomization of electronic cigarette atomizers and electronic cigarette atomizers, and achieves the effects of preventing oil leakage, facilitating assembly, and avoiding oil frying in the airway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments.

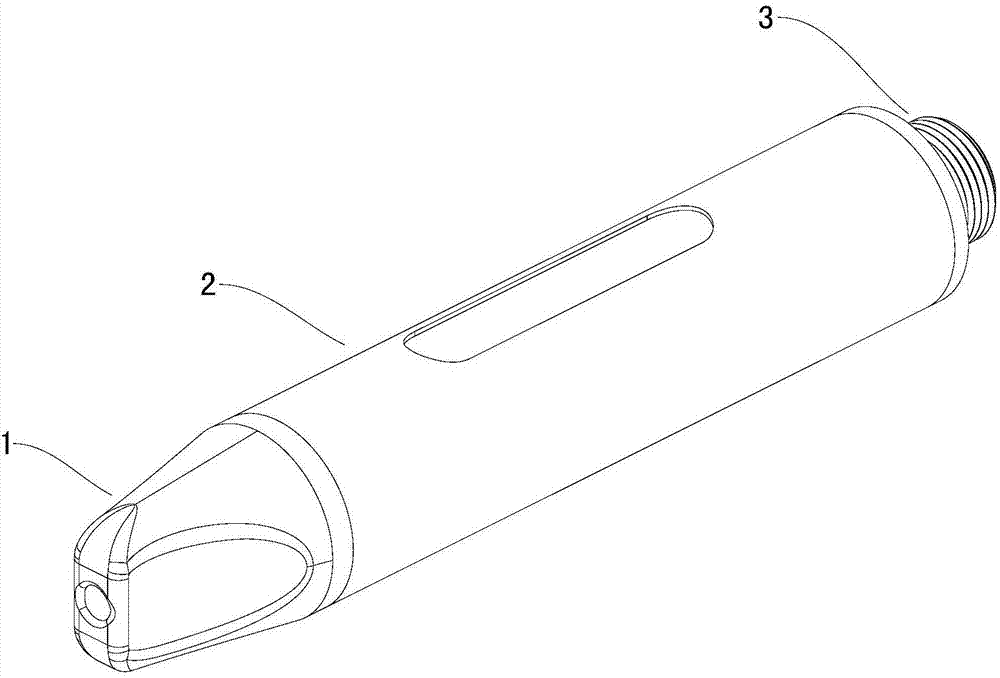

[0023] refer to figure 1 In some embodiments, the novel electronic cigarette vaporizer includes a rod-shaped main body 2 , a suction nozzle 1 arranged at the rear end of the main body 2 , and a power connection seat 3 arranged at the front end of the main body 2 .

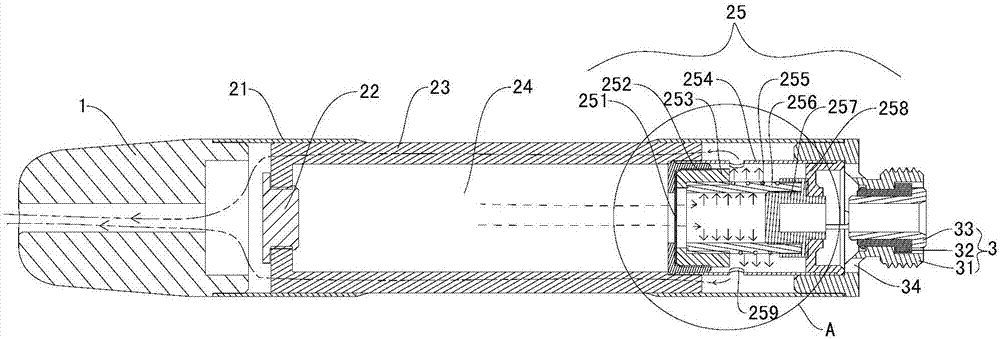

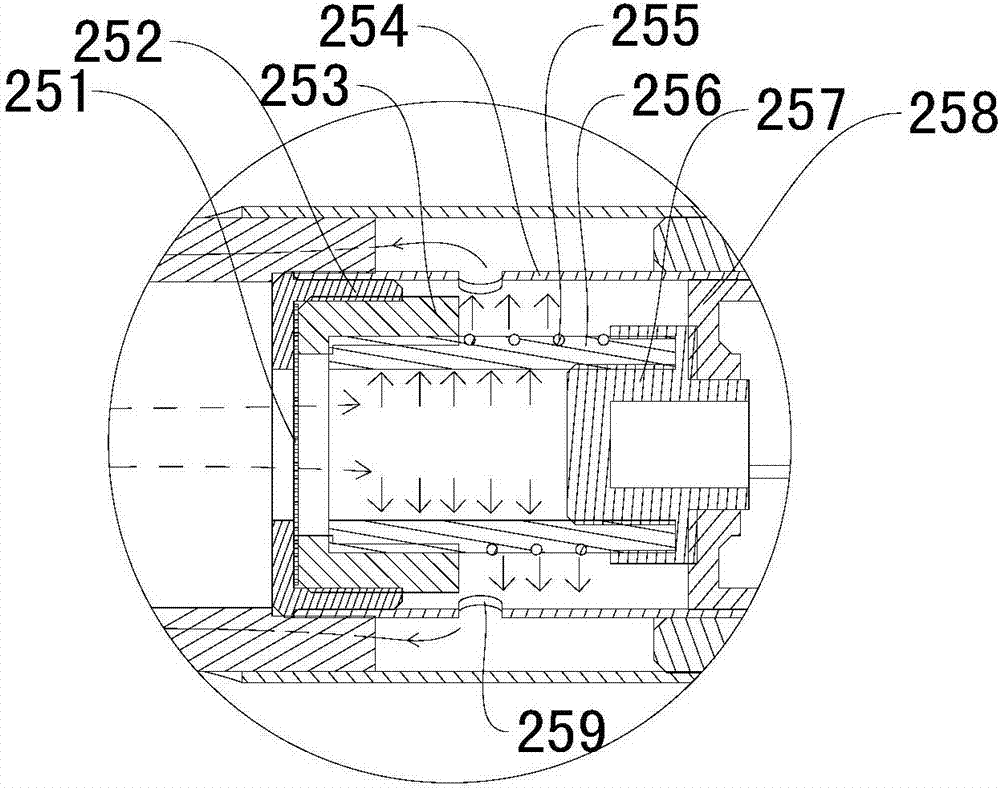

[0024] in the attached Figure 4 Some parts are omitted from the Figure 1 to Figure 4 , the main body 2 includes a first pipe body 21 and an oil storage device 23 and an atomizing core assembly 25 arranged in the first pipe body 21 . The oil storage device 23 and the atomizing core assembly 25 are both rod-shaped, the oil storage device 23 is arranged on the front side of the suction nozzle 1 , and the atomizing core assembly 25 is arranged on the front side of the oil storage device 23 and passes through the front end of the oil storage device 23 The rear end of the power connection base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com