Automatic fermentation tank for tea processing and production

An automatic fermentation and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of tea processing quality decline, black tea quality unevenness, human error quality, etc., to avoid tea quality decline, improve processing quality, and reduce waste rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

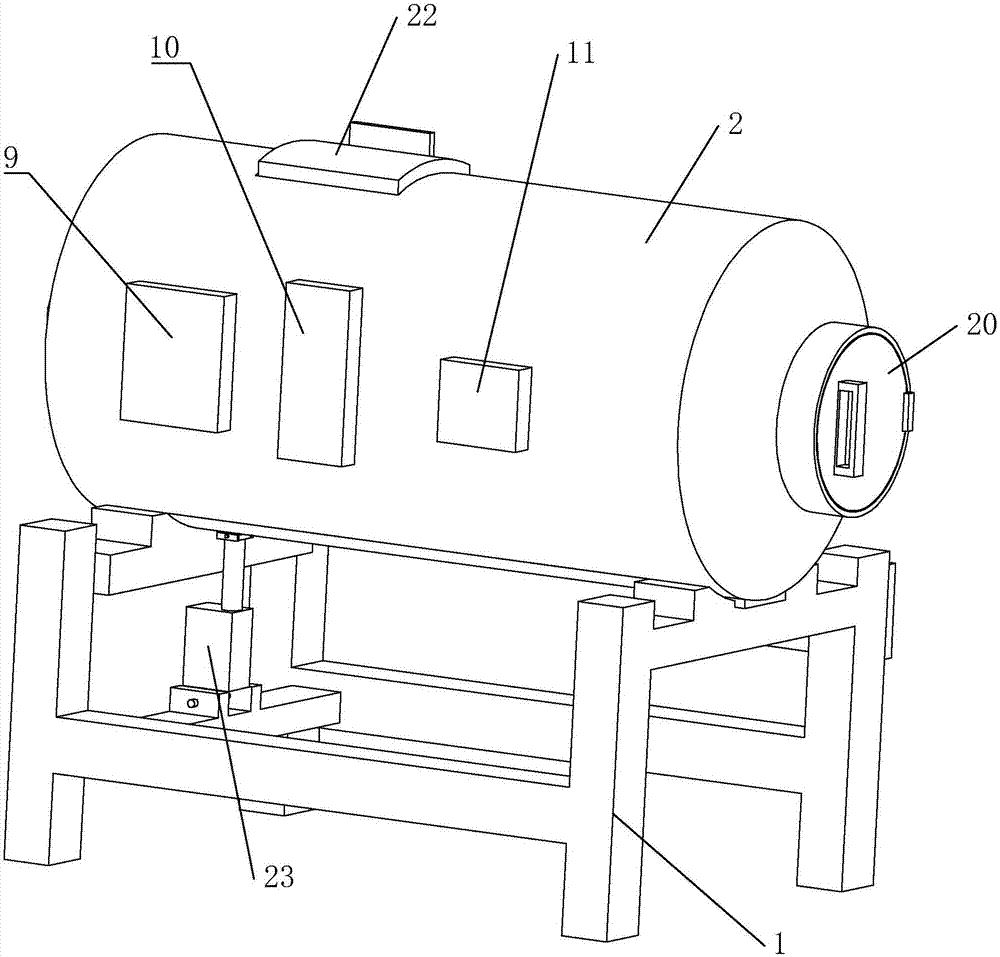

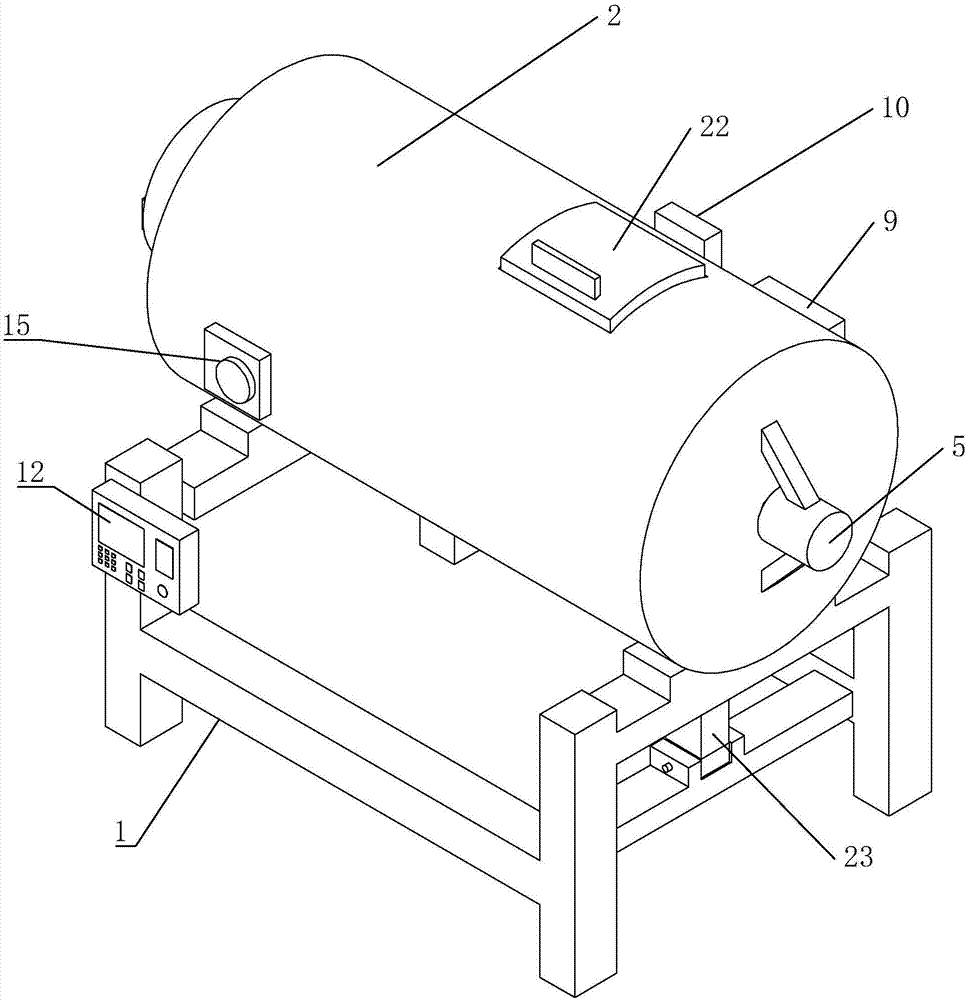

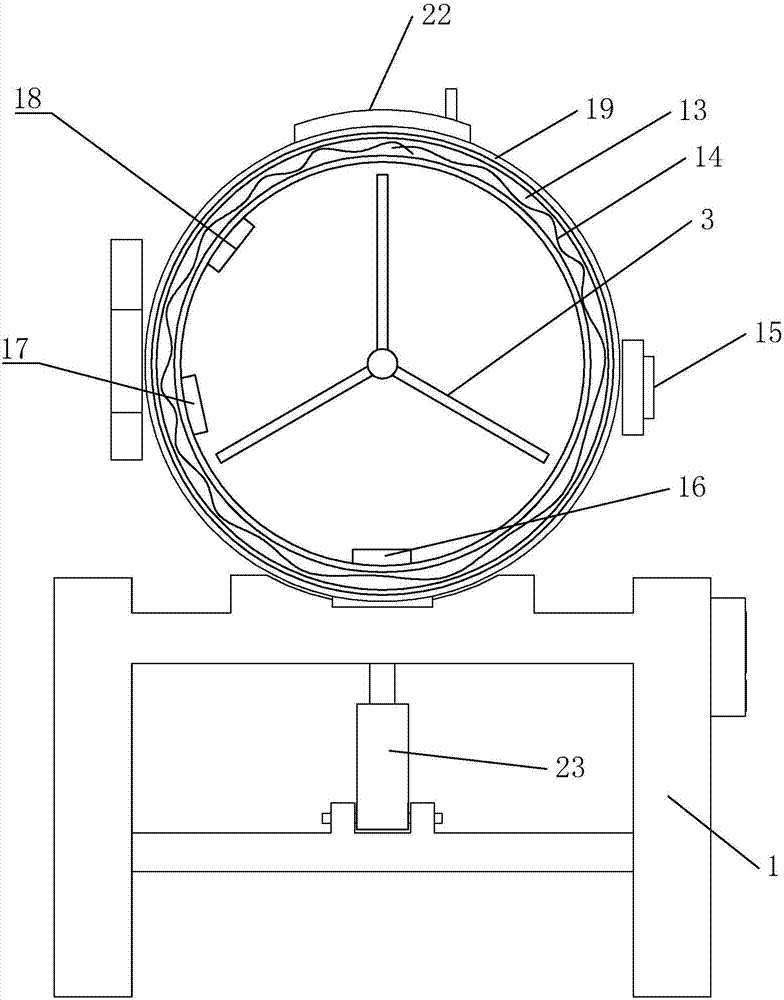

[0021] refer to Figures 1 to 5 As shown, an automatic fermenter for tea processing and production in this embodiment includes a frame 1, a tank body 2 and a stirring rod 3 that is rotatably arranged in the tank body 2. The tank body 2 is open at one end, and the other is One end is closed and set, and the tank body 2 is horizontally arranged on the frame 1. A motor 5 is arranged on the outside of the closed end of the tank body 2, and a through hole 4 is arranged at the center of the closed end face of the tank body 2. The motor 5 The rotating shaft of the rotating shaft passes through the through hole 4 and then is linked to the rotating shaft of the stirring rod 3 in the tank body 2. The tank body 2 is provided with a humidifying hole 6, a ventilation hole 7 and a ventilation hole 8 connected to the tank body 2. The tank body 2 The body 2 is provided with a humidifier 9, the outlet of the humidifier 9 is connected to the humidification hole 6, and the tank body 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com