Soil loosing ridging machine

A ridge machine and frame technology, which is applied to agricultural machinery and implements, shovels, plows, etc., achieves the effects of easy processing and manufacturing, loosening the soil in ridges and furrows, and breaking the bottom of the plough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

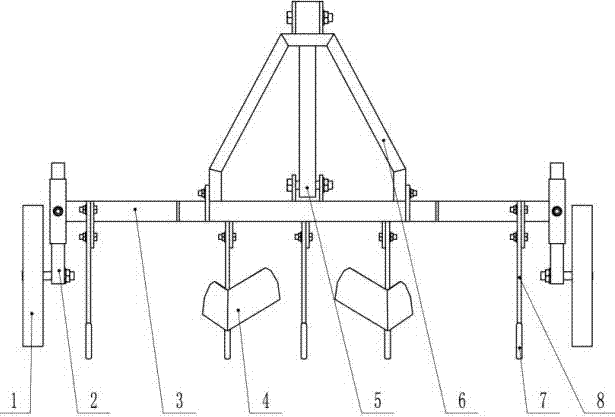

[0014] as attached figure 1 , attached figure 2 As shown, a soil loosening ridge machine, the frame 3 is the framework for installing parts of the whole machine, the suspension frame 6 is installed on the front upper part of the frame 3, and is mainly connected with the tractor, the front end of the pull rod 5 is connected to the suspension frame 6, and the rear end is connected The upper part of the rear beam of the frame 3 plays the role of improving the strength of the frame 3. The adjustment arm 2 has holes and is installed on the left and right sides of the frame 3. The depth-gauge wheel 1 is installed on the adjustment arm 2 through bolts. The installation height of the depth-gauge wheel 1 can be adjusted by the installation position of the adjustment arm 2 to achieve a perfect alignment with the whole machine. The working depth is limited. A plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com