Novel carbon powder box detecting device and carbon powder box

A technology for detection devices and toner cartridges, applied in electrography, optics, instruments, etc., can solve the problems of undetectable toner cartridges, high defect rate, and high cost pressure, so as to improve market competition rate and ensure Manufacturing quality and the effect of reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

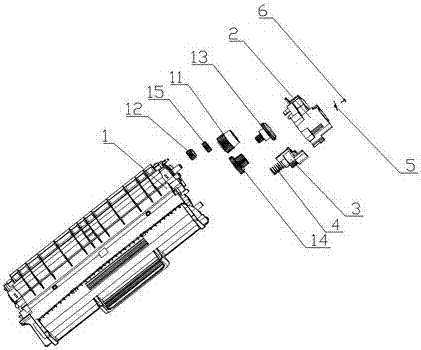

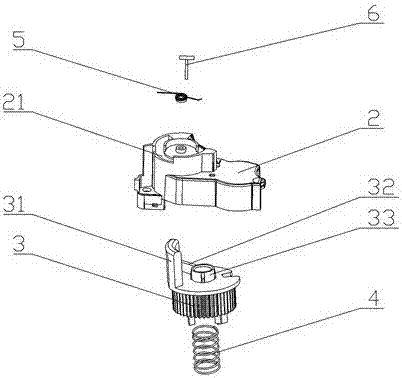

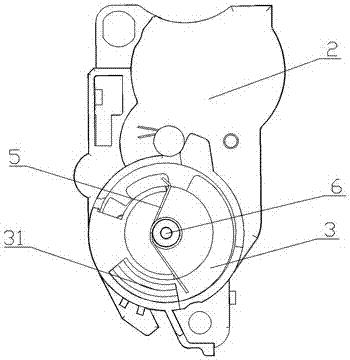

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the toner cartridge of the present invention mainly includes a toner cartridge body 1, a stirring frame arranged in the toner cartridge body 1, a developing roller and a powder feeding roller (another charging roller, a powder discharge scraper, etc. are existing technology, not described here), the gear transmission mechanism arranged on the side wall of the toner cartridge body 1, and the end cover 2 arranged on the side of the toner cartridge body 1 and matched with the gear transmission mechanism , the stirring frame, the powder feeding roller and the developing roller are fixed on the two side walls of the toner cartridge body 1, and rotated by the gear transmission mechanism, the gear transmission mechanism described The gear transmission mechanism comprises a driving gear 11, a developing roller gear 12 meshed with the driving gear 11 and the transmission gear 13, and a powder feeding roller gear 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com