Reflection lens and ultra-thin backlight module thereof

A reflective lens and backlight module technology, applied in the field of lens and backlight, can solve the problems of reducing overall thickness, temperature rise, light energy loss, etc., to reduce the number of PCB boards, improve brightness uniformity, and improve corner brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

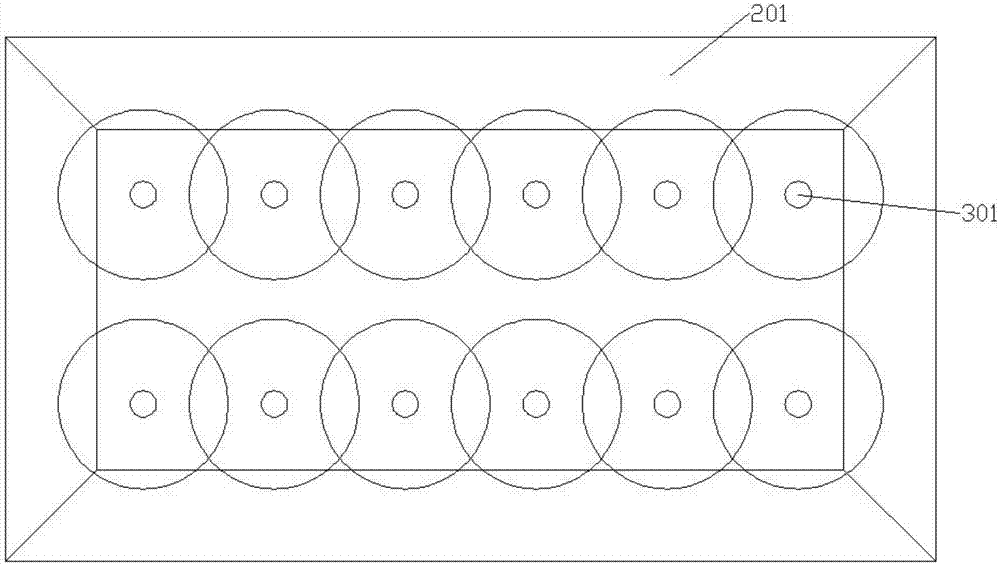

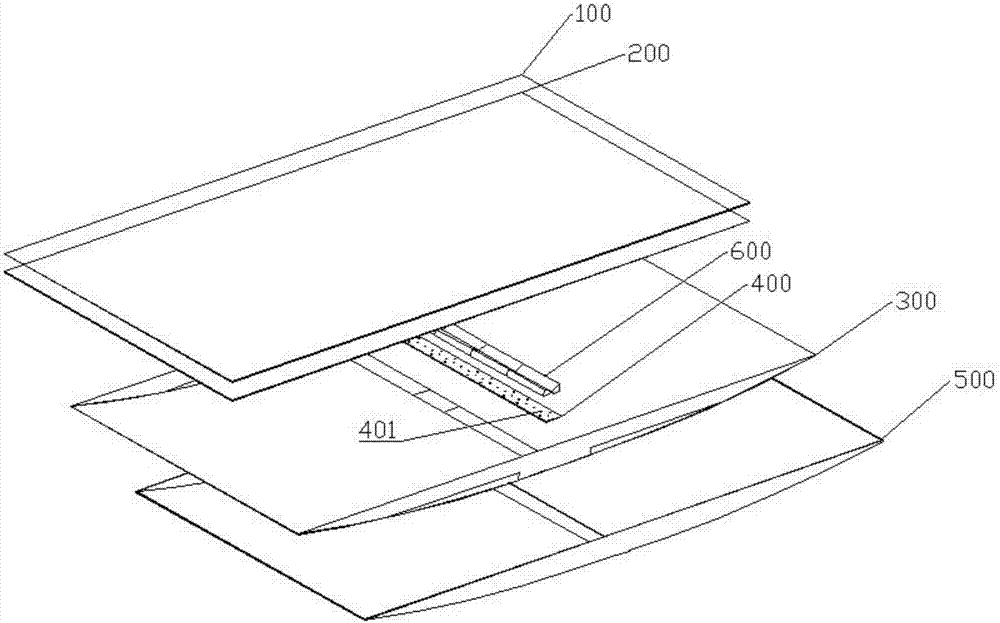

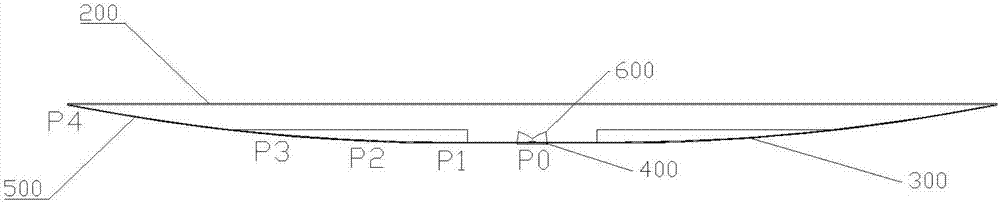

[0040] refer to Figure 2 to Figure 9 , the present invention provides a reflective lens and its ultra-thin backlight module, see Figure 5 , Figure 6 and Figure 7 In this embodiment, the reflective lens 600 is composed of two symmetrical parts, and the overall shape is roughly rectangular; the reflective lens 600 includes an exit surface 601, an incident surface 602, a bottom fog surface 603, a column base 604 and a reflection surface 605, see Figure 7 , the column foot 604 is installed on the bottom matte surface 603, the incident surface 602 is a left-right symmetrical concave shape, the external CSP light source 401 is located at the concave center of the incident surface 602, the bottom matte surface 603 is connected with the incident surface 602; the exit surface 601 are respectively connected to the bottom matte surface 603 and the reflective surface 605; the outgoing surface 601 and the reflective surface 605 are symmetrically arranged on the left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com