Automatic detection line for mechanical parts

A technology for automatic detection and mechanical parts, applied in measuring devices, instruments, optical devices, etc., can solve problems such as inability to cope with all inspections of large quantities of parts, inability to adapt to the development trend of the manufacturing industry, and heavy workload of inspection personnel, and achieve data The presentation is more timely, more traceable, and the detection is convenient, fast and accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

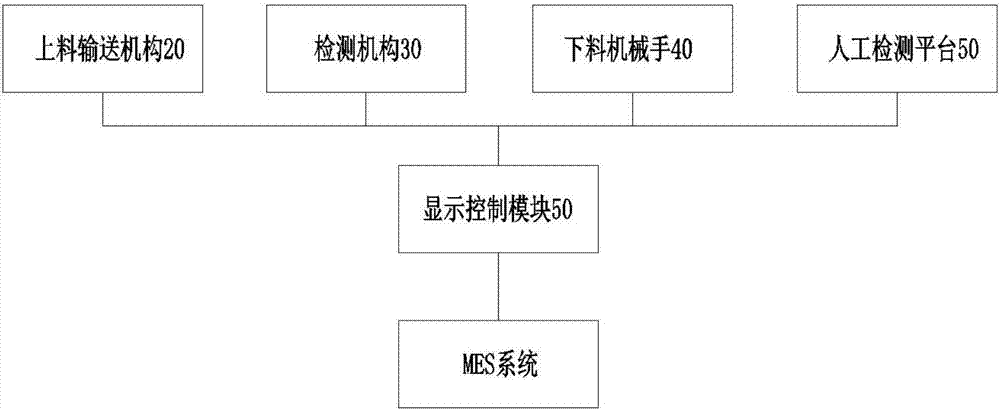

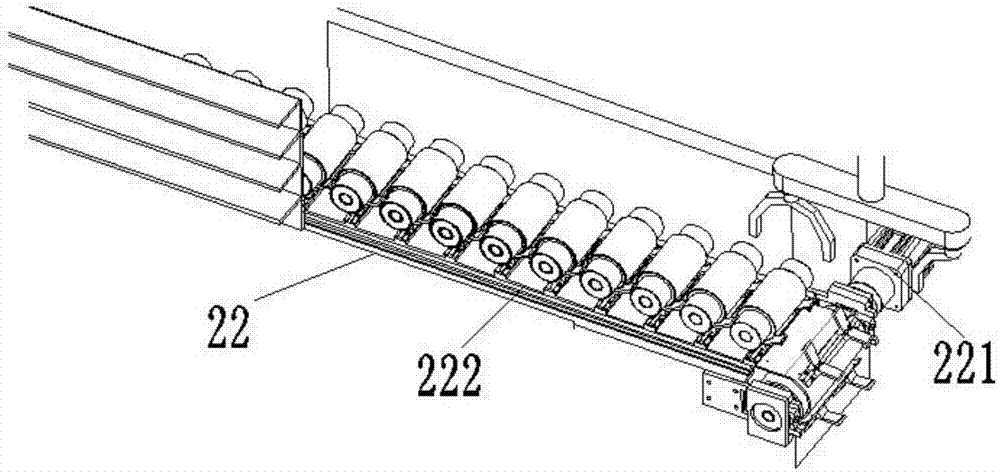

[0033] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the automatic detection line for mechanical parts of the present invention, figure 2 It is a control block diagram of the automatic detection line of mechanical parts of the present invention. The automatic inspection line for mechanical parts of the present invention includes a base 10 , a feeding and conveying mechanism 20 , a testing mechanism 30 , a feeding manipulator 40 , a manual inspection platform 50 and a display control module 60 . The feeding and conveying mechanism 20 and the detection mechanism 30 are arranged on the base 10 in turn. The feeding and conveying mechanism 20 is used for feeding and conveying the parts, and the detection mechanism 30 is used for dimension detection and projection detection of the parts and marking of the qualified parts Marking; the blanking manipulator 40 is arranged at the tail end of the detection mechanism 30, and the blanking manipulator 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com