Staged Continuous Fermentation Technology of Clostridium butyricum

A clostridium butyricum, segmented and continuous technology, applied in the field of microbial fermentation, can solve problems such as poor bacterial growth and difficult fermentation production, and achieve the effects of reducing pollution opportunities, increasing the number of viable fermentation bacteria, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

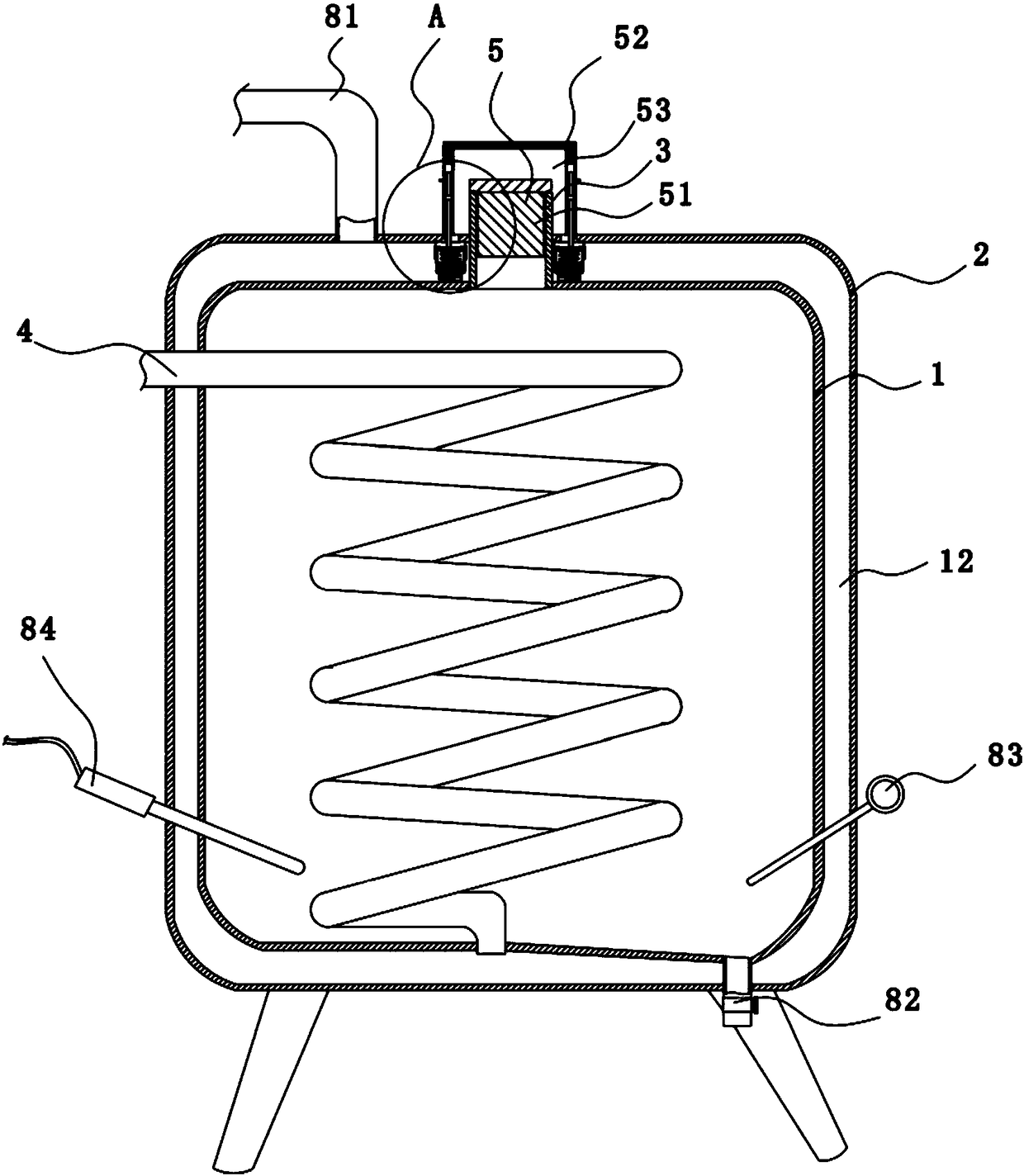

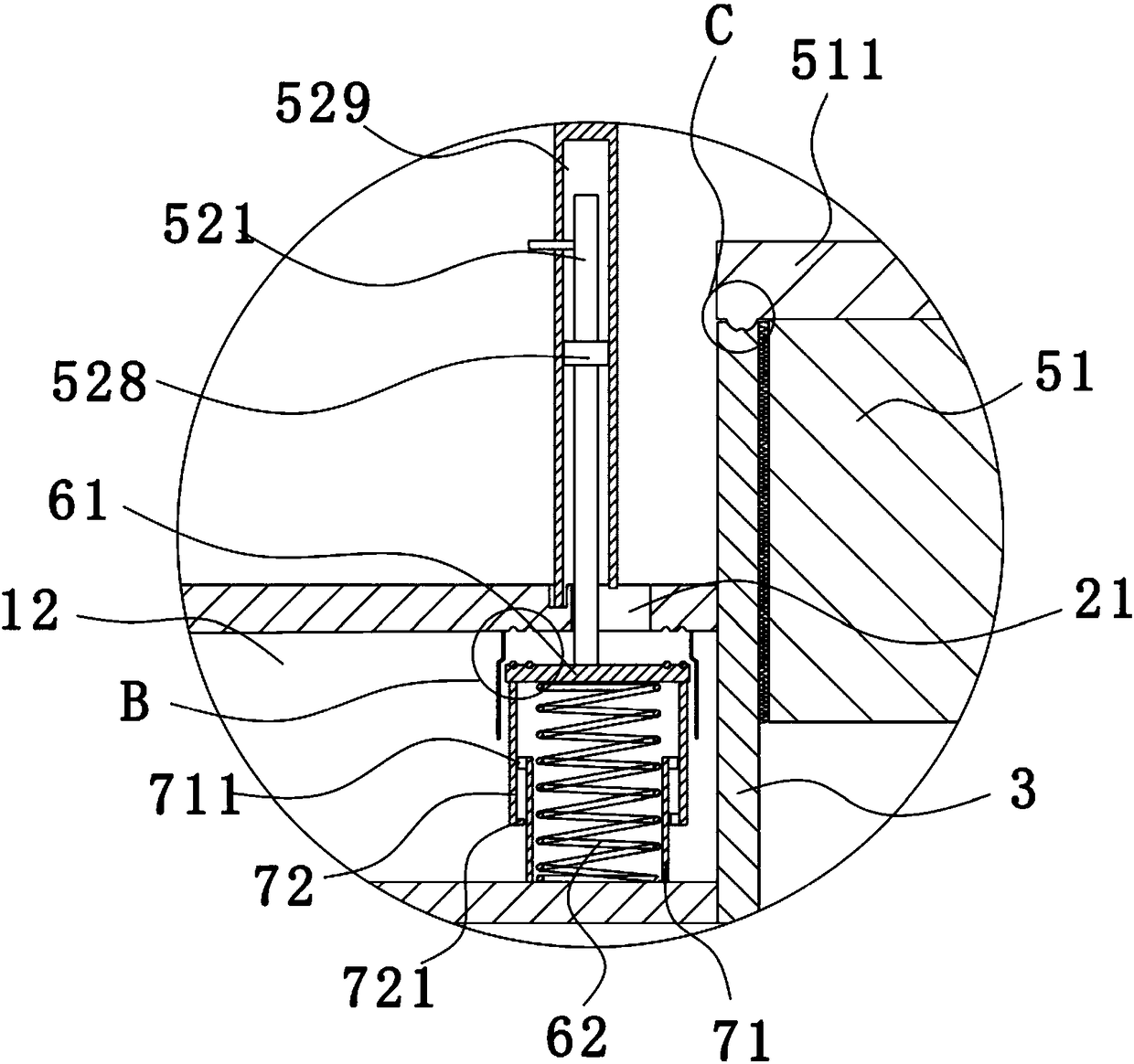

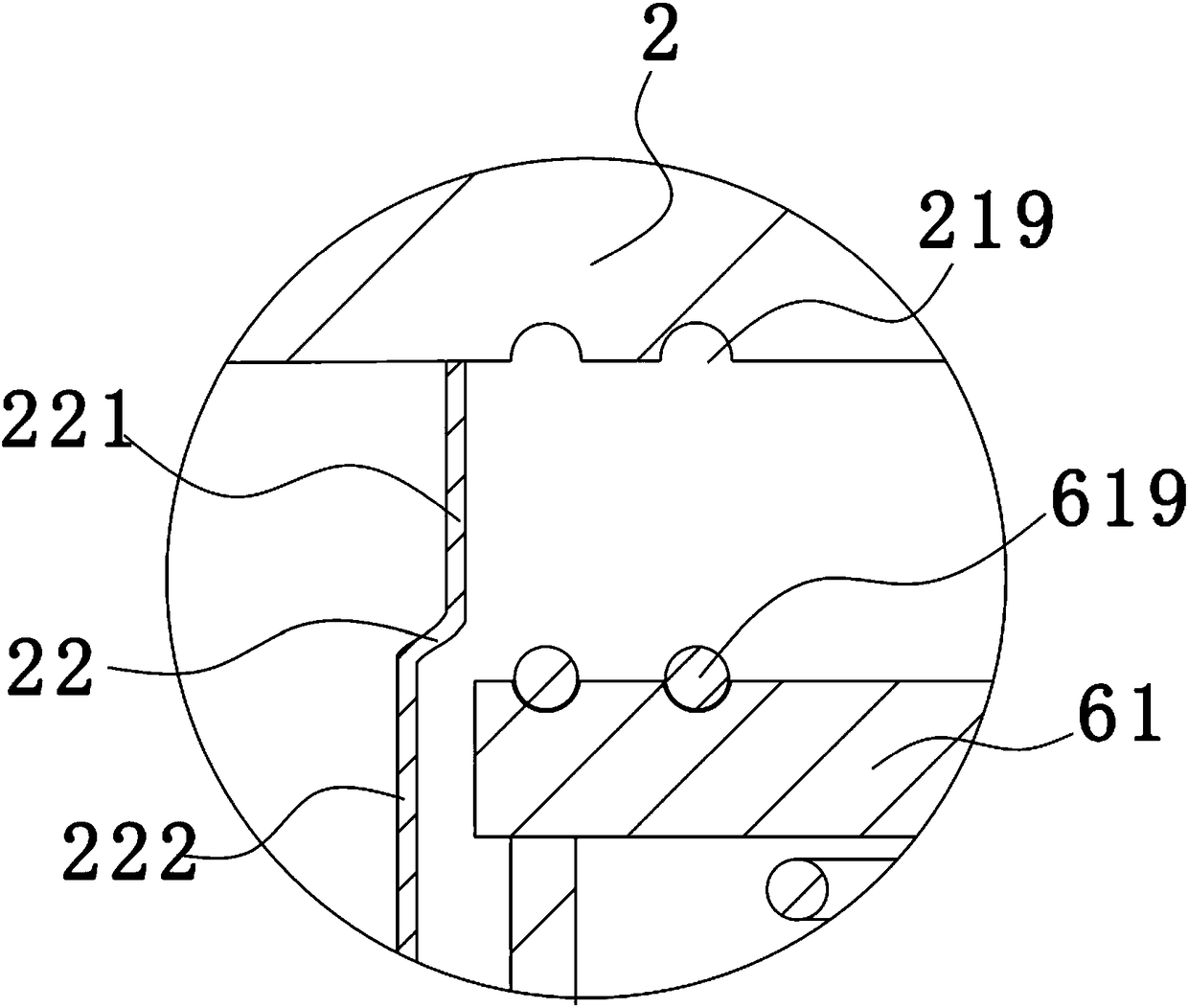

[0029] A staged continuous fermentation process of clostridium butyricum, comprising the following steps:

[0030] (1) Carry out test tube culture, Erlenmeyer flask deep layer culture, seed tank expansion culture successively to Clostridium butyricum, obtain Clostridium butyricum bacterial liquid with this; Wherein test tube culture is: the Clostridium butyricum strain in the cryopreservation tube, Place in a test tube with a liquid medium and cultivate for 48 hours; then place the test tube in a water bath at 80° C. for 10 min, then insert the Clostridium butyricum in the test tube into 500 ml (200 ml) seed medium, Cultivate at a temperature of 37°C and under anaerobic conditions for 8 hours; the deep layer culture of the Erlenmeyer flask is as follows: the Clostridium butyricum after being cultivated in the seed medium is inserted into a 5L Erlenmeyer flask with a liquid volume of 2L according to the inoculation amount of 5%. Continue culturing for 8 hours in the medium; the...

Embodiment 2

[0041] A staged continuous fermentation process of clostridium butyricum, comprising the following steps:

[0042] (5) Carry out test tube culture, Erlenmeyer flask deep layer culture, seed tank expansion culture successively to Clostridium butyricum, obtain Clostridium butyricum bacterial liquid with this; Place in a test tube with a liquid medium and cultivate for 48 hours; then place the test tube in a water bath at 80° C. for 10 min, then insert the Clostridium butyricum in the test tube into 500 ml (200 ml) seed medium, Cultivate at a temperature of 37°C and under anaerobic conditions for 8 hours; the deep layer culture of the Erlenmeyer flask is as follows: the Clostridium butyricum after being cultivated in the seed medium is inserted into a 5L Erlenmeyer flask with a liquid volume of 2L according to the inoculation amount of 5%. Continue culturing for 8 hours in the medium; the expanded cultivation of the seed tank is as follows: the Clostridium butyricum after culture...

Embodiment 3

[0049]A staged continuous fermentation process of clostridium butyricum, comprising the following steps:

[0050] (9) Carry out test tube culture, Erlenmeyer flask deep layer culture, seed tank expansion culture successively to Clostridium butyricum, obtain Clostridium butyricum bacteria liquid with this; Place in a test tube with a liquid medium and cultivate for 48 hours; then place the test tube in a water bath at 80° C. for 10 min, then insert the Clostridium butyricum in the test tube into 500 ml (200 ml) seed medium, Cultivate at a temperature of 37°C and under anaerobic conditions for 8 hours; the deep layer culture of the Erlenmeyer flask is as follows: the Clostridium butyricum after being cultivated in the seed medium is inserted into a 5L Erlenmeyer flask with a liquid volume of 2L according to the inoculation amount of 5%. Continue culturing for 8 hours in the medium; the expanded cultivation of the seed tank is as follows: the Clostridium butyricum after cultured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com