Oil filling barrel of drilling tool protective agent

A technology of protecting agent and refueling barrel, which is applied in the direction of preventing repeated filling of containers, closing, packaging, etc., can solve problems such as waste of resources, and achieve the effect of saving oil resources and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

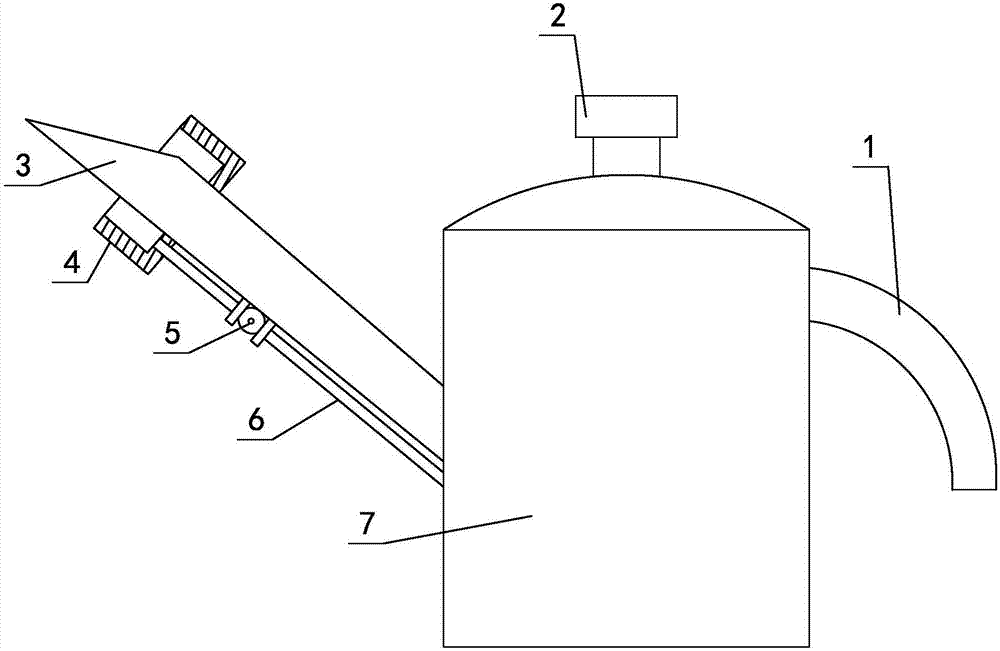

[0014] Such as figure 1 As shown, the refueling barrel of the drilling tool protective agent includes a barrel body 7, and an oil outlet pipe is arranged obliquely on the left side wall of the barrel body 7. The side walls are connected and communicated. A collection tank 4 is provided at the fuel nozzle 3 near the oil outlet pipe. The bottom of the collection tank 4 is provided with a through hole. The oil outlet pipe is installed in the through hole and is sealed and fixed. The bottom is connected with a refueling pipe 6; one end of the refueling pipe 6 is connected to the collection tank 4, and the other end is connected to the barrel body 7; a check valve 5 is installed on the refueling pipe 6, and the check valve 5 is used to prevent the The oil flows out from the filler pipe 6.

[0015] In this embodiment, the top of the bucket body 7 is provided with a bucket lid 2 which is fastened therewith; the right side wall of the bucket body 7 is provided with a handle 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com