Conveyor belt puncher

A conveyor belt punching, conveyor belt technology, applied in the direction of metal processing, cleaning methods and tools, cleaning hollow objects, etc., can solve problems such as troublesome, residual blanking of the blanking bucket, difficult cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

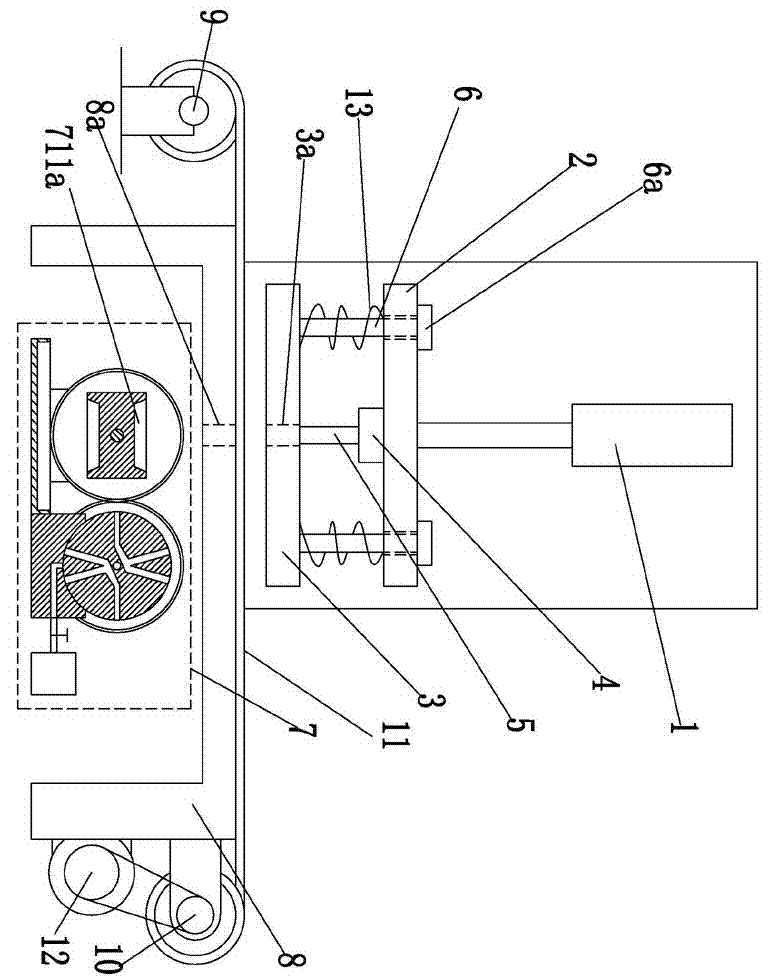

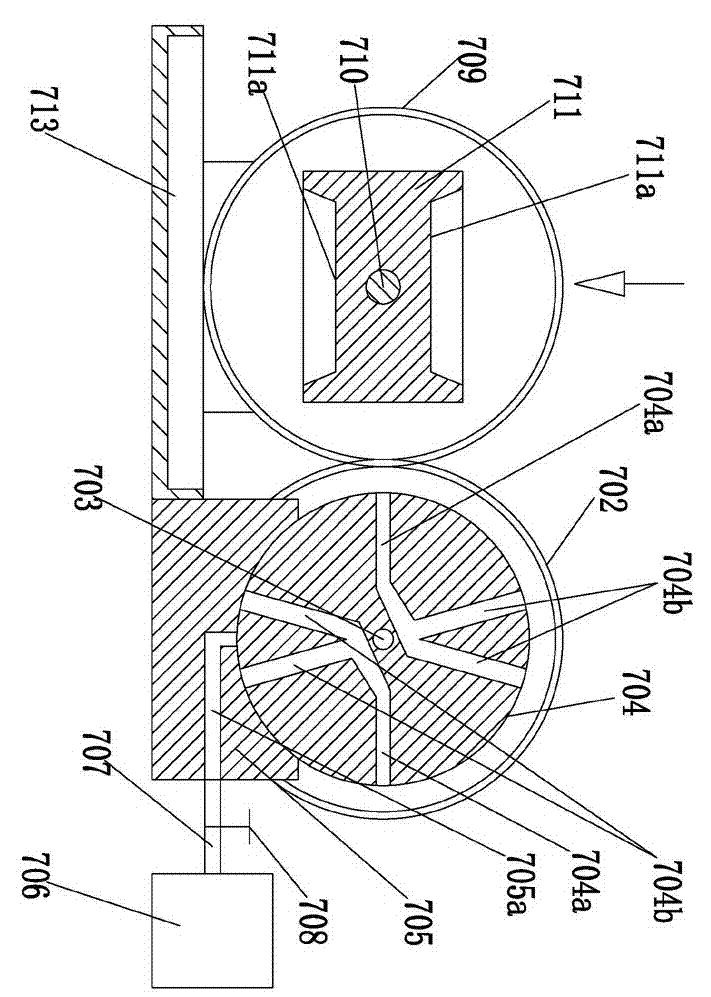

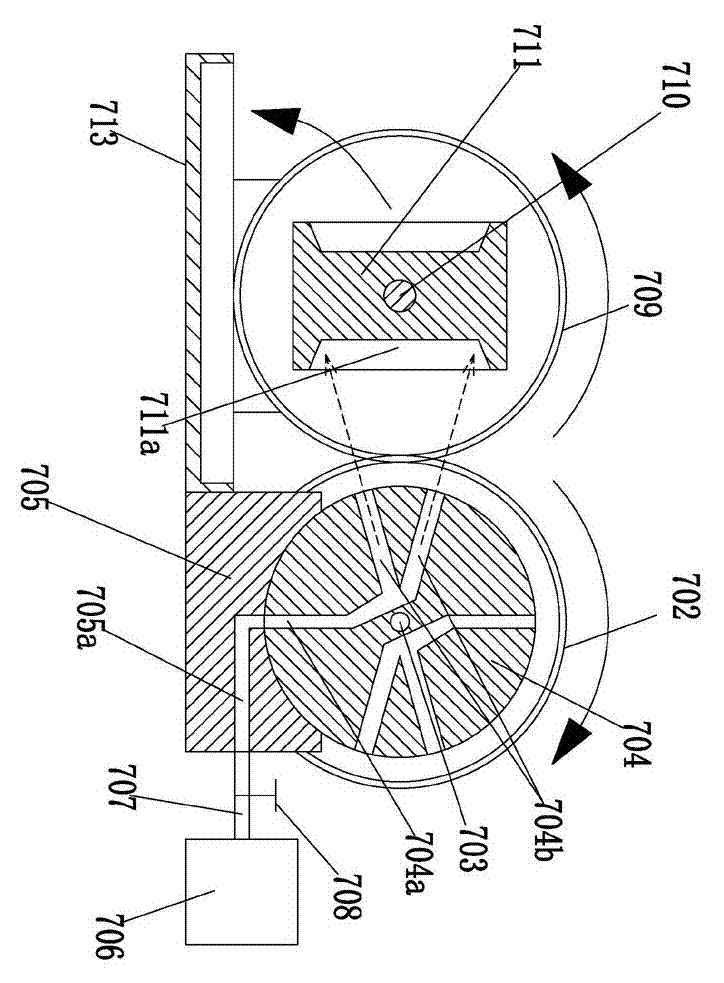

[0021] Such as Figure 1-5 As shown, the conveyor belt punching machine includes a frame 8, a drill bit 5 for drilling holes in the conveyor belt 11, a drilling motor 4 that drives the drill bit 5 to rotate, and a frame mounted on the frame that can be vertically lifted. 8, the buoyancy platform 2 installed together with the drilling motor 4 also includes a stamping drive mechanism 1 that can control the buoyancy platform 2 to carry out vertical lifting, and also includes a conveyor belt 11 for winding the unperforated, The feeding roller 9 that is rotatably installed on the frame 8 also includes a receiving roller 10 that is rotatably installed on the frame 8 for winding the perforated conveyor belt 11, and also includes a receiving roller 10 that is used to drive the The material roller 10 rotates the material receiving motor 12 for receiving material, and also includes a PLC controller 14, and the stamping drive mechanism 1, the drilling motor 4, and the material receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com