Multi-head metal composite plate polishing machine

A metal composite board and polishing machine technology, which is applied to surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of injury to staff, high labor costs, low reliability, etc., and improve production Efficiency, low input cost, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

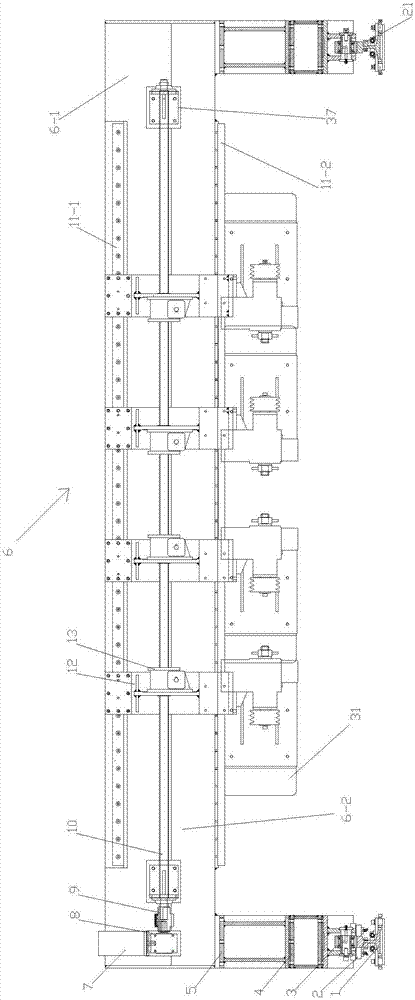

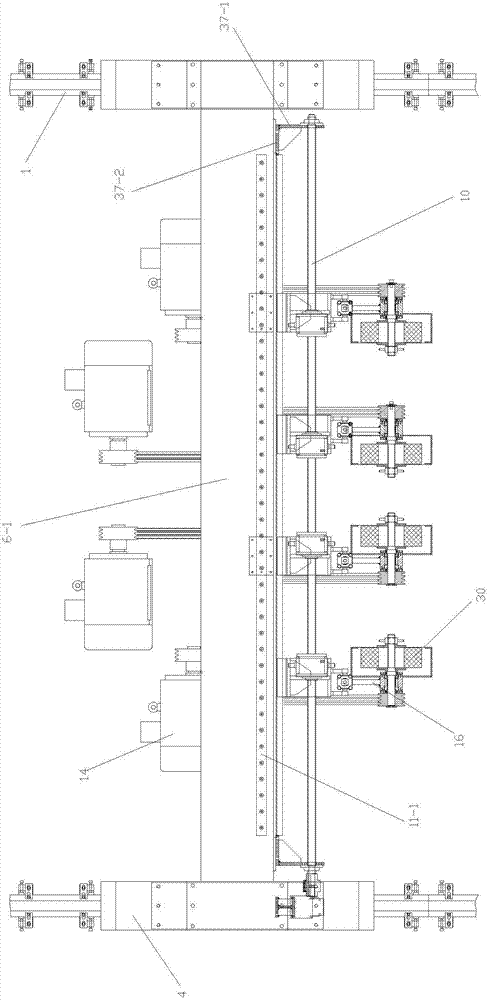

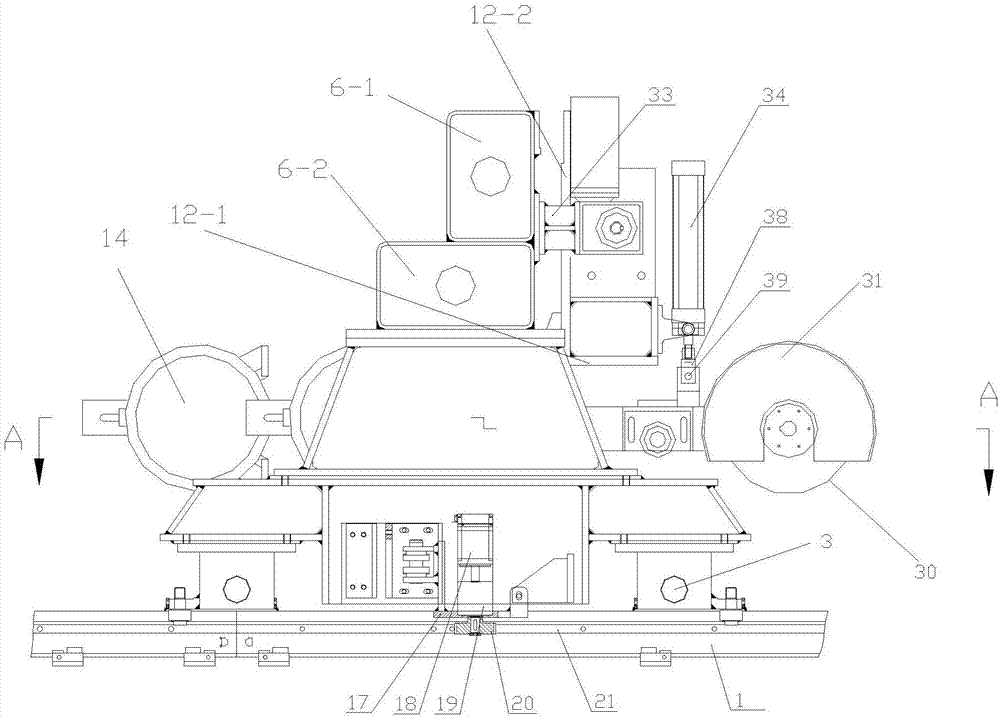

[0058] Such as figure 1 , figure 2 and Figure 5 As shown, the present invention includes a guide rail device installed on the ground, a car body device slidably installed on the guide rail device, a polishing device installed on the car body device, and monitoring of the car body device and the polishing device monitoring device;

[0059] The vehicle body device includes a crossbeam 6, a traveling mechanism mounted symmetrically on both ends of the crossbeam 6 and located on the guide rail device, and a traveling drive mechanism that drives the movement of the traveling mechanism.

[0060] The polishing device includes a lead screw 10 installed on one side of the beam 6 and arranged along the length direction of the beam 6, a polishing mechanism for polishing the metal composite plate and a polishing drive mechanism for driving the polishing mechanism, and driving the The polishing mechanism lifts up and down and can be close to or away from the rocker mechanism of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com