Self-adaptive hydraulic cyclone desilting method for big turbidity change

A hydrocyclone and self-adaptive technology, applied in chemical instruments and methods, separation methods, settling tanks, etc., can solve problems such as large equipment maintenance, difficult sludge discharge, unstable effluent quality, etc., to improve equipment reliability, Improve the flocculation effect and improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

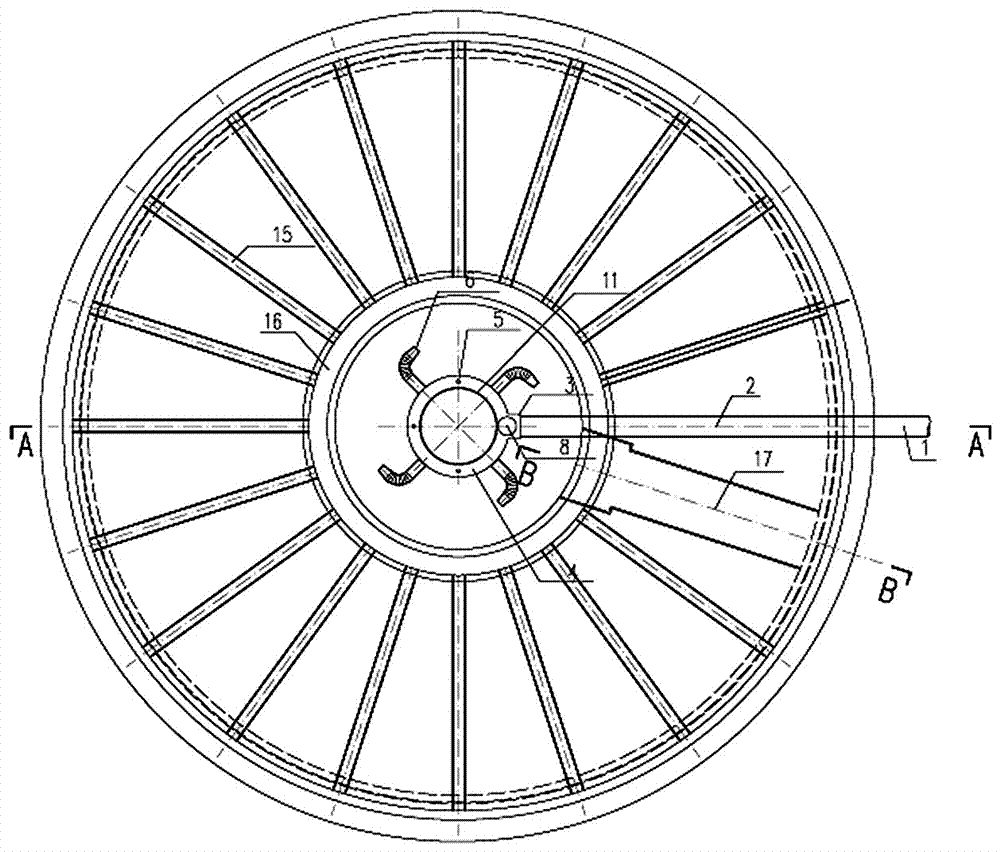

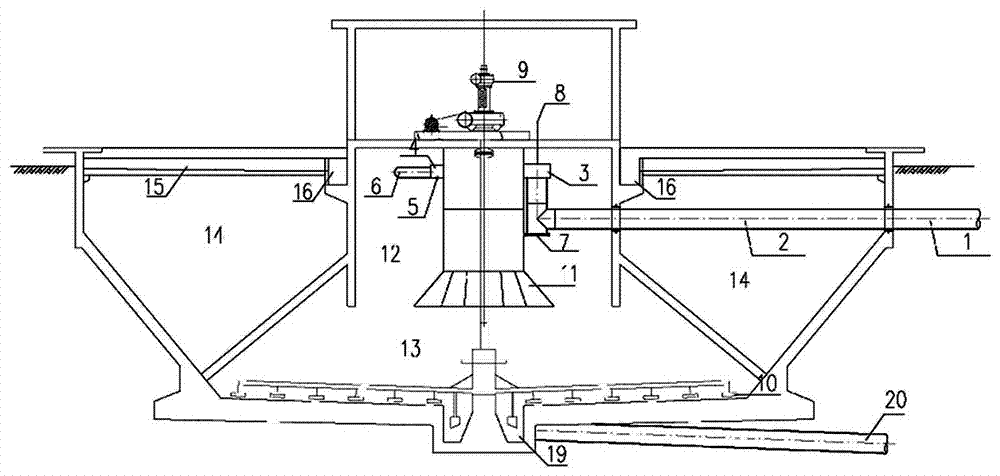

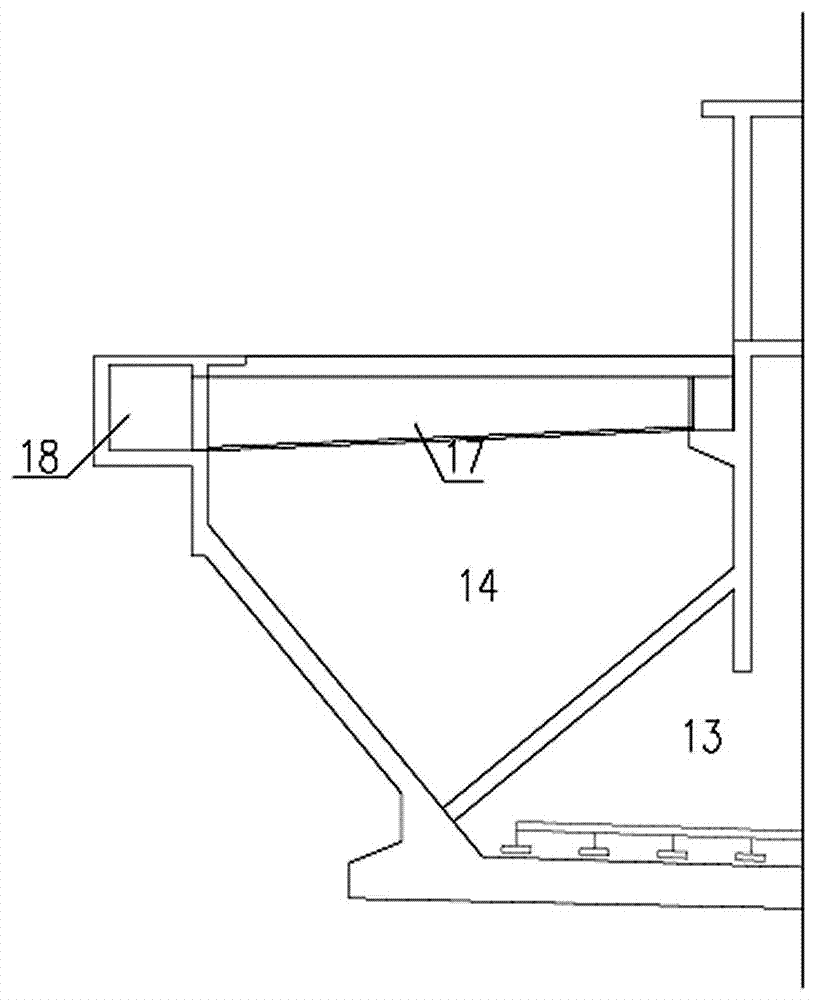

[0027] The present invention is a self-adaptive hydrocyclone sedimentation method used for large turbidity changes. As shown in the accompanying drawings, the example is basically a circular truncated pool body, consisting of a flocculation zone 12, a sludge concentration zone 13, and a separation zone 14. composition. Therefore, the present invention integrates rapid mixing, hydraulic flocculation and mud-water separation. Process of the present invention is as follows:

[0028] Raw water enters the tank body from the water inlet pipe 2 through the water inlet main pipe 1, and an inorganic salt coagulant or a polymer flocculant is added to the first place according to the water quality conditions. Through the water inlet pipe 2 , the raw water enters the annular rectangular distribution pipe 4 surrounding the adjustable guide tube 11 from the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com