A double-layer explosion-proof fire extinguisher

A fire extinguisher, double-layer technology, applied in the field of double-layer explosion-proof fire extinguishers, can solve the problems of unscientific technology, high cost, shortening the service life of the cylinder, etc., and achieve the effects of safe and reliable structure, scientific manufacturing process, and safe and reliable cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS As will be further detailed in connection with the accompanying drawings, the technical solution of the present invention is more readily understood and grasped.

[0029]In this embodiment, it is to be understood that the term "middle", "upper", "lower", "top", "right side", "left", "above", "back", "middle", etc. The orientation or positional relationship indicated is based on the orientation or positional relationship shown in the drawings, but is intended to facilitate the description of the present invention, rather than indicating or implying that the device or element must have a specific orientation, and to operate and operate Therefore, it is not understood to be the limitations of the present invention.

[0030]Further, in the particular embodiment, the connection or fixing method can be fixed or fixed by the prior art, such as the connection or fixing method, such as the connection or fixing method, or the pin-pin fixed, or...

Embodiment 1

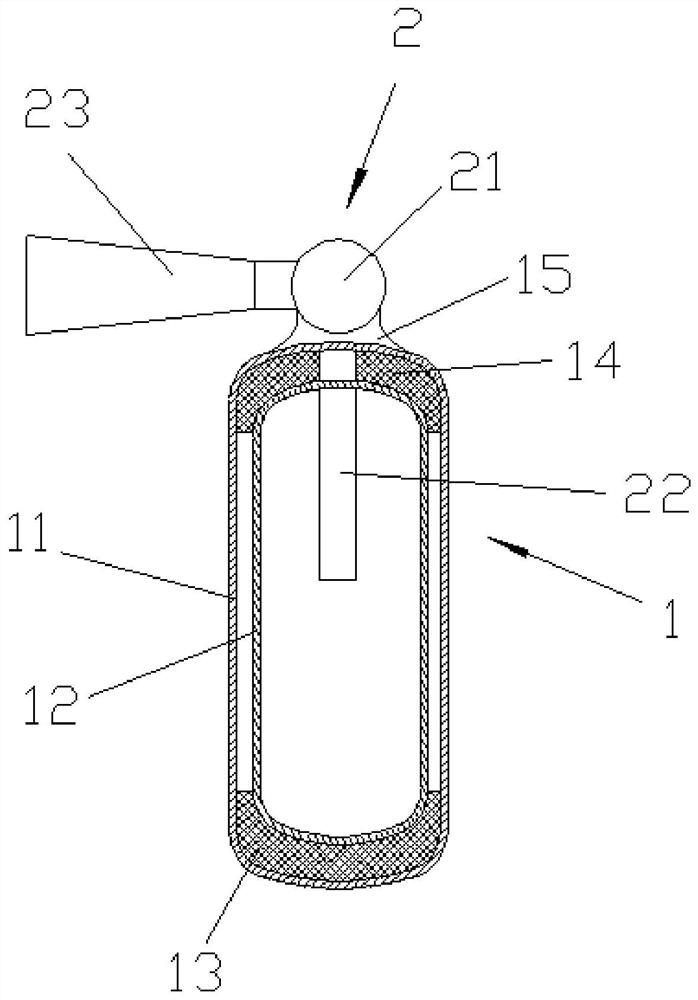

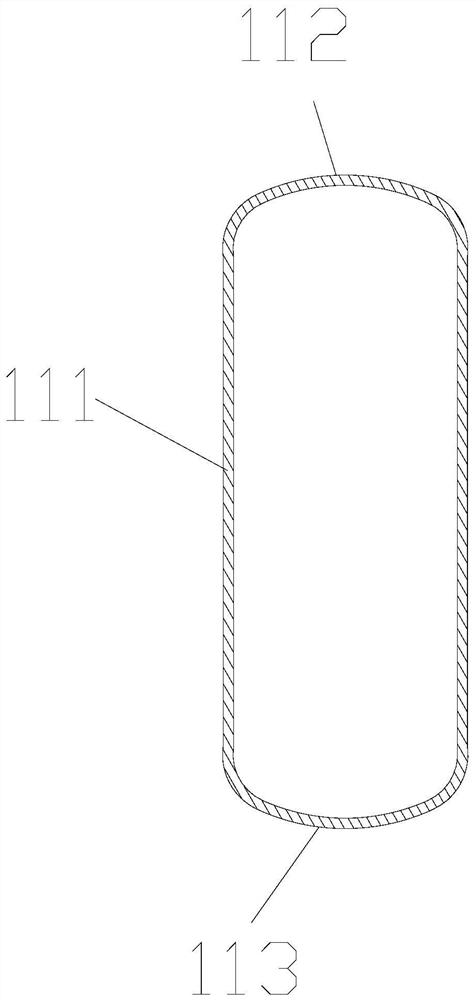

[0032]A double-layer explosion-proof fire extinguisher, such asfigure 1 As shown, including the bottle body 1, and is provided on the upper end of the bottle body 1, and the bottle body 1 is rotated by a valve seat 2 that is fixedly coupled, the bottle body 1 includes an outer cylinder 11, and is provided inside the outer cylinder 11 Bell 12, the upper end of the outer cylinder 11 is further provided with a steel ring 15 for supporting the valve seat 2 for supporting the upper head 112. Such asfigure 2As shown, the outer cylinder 11 includes an outer cylinder body 111 and is provided above the outer cylinder body 111, and is fixed to the outer tube body 111, which is fixed, and is provided below the outer cylinder body 111. Further, with the outer cylinder body 111, the next head 113 for sealing is fixed. The structure of the inner cylinder 12 is consistent with the structure of the outer cylinder 11. The bottom of the inner cylinder 12 is provided with a lower pedestal 13, and the ...

Embodiment 2

[0048]A double-layer explosion-proof fire extinguisher, such asfigure 1 As shown, including the bottle body 1, and is provided on the upper end of the bottle body 1, and the bottle body 1 is rotated by a valve seat 2 that is fixedly coupled, the bottle body 1 includes an outer cylinder 11, and is provided inside the outer cylinder 11 Bell 12, the upper end of the outer cylinder 11 is further provided with a steel ring 15 for supporting the valve seat 2 for supporting the upper head 112. Such asfigure 2As shown, the outer cylinder 11 includes an outer cylinder body 111 and is provided above the outer cylinder body 111, and is fixed to the outer tube body 111, which is fixed, and is provided below the outer cylinder body 111. Further, with the outer cylinder body 111, the next head 113 for sealing is fixed. The structure of the inner cylinder 12 is consistent with the structure of the outer cylinder 11. The bottom of the inner cylinder 12 is provided with a lower pedestal 13, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com