Resistive-capacitive deformation sensor

A technology of undeformed and deformed analysis, applied in the direction of electric/magnetic solid deformation measurement, instruments, electromagnetic measuring devices, etc., can solve the problems of lack of identification and distinction of different types of deformation, resistance strain gauge lack of distinction between bending deformation and stretching deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

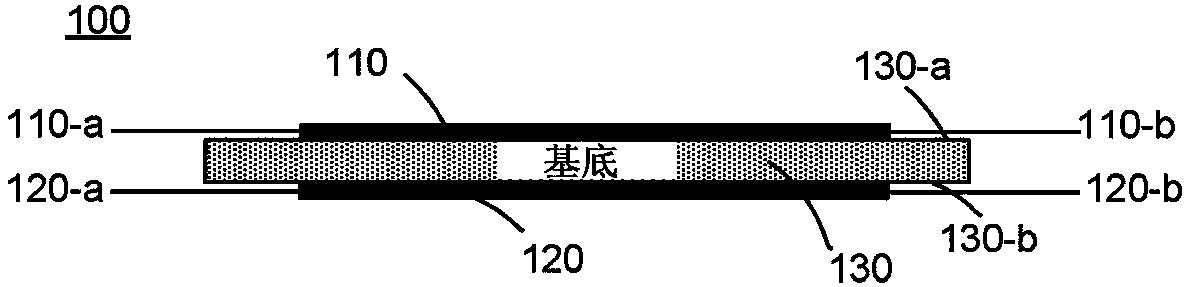

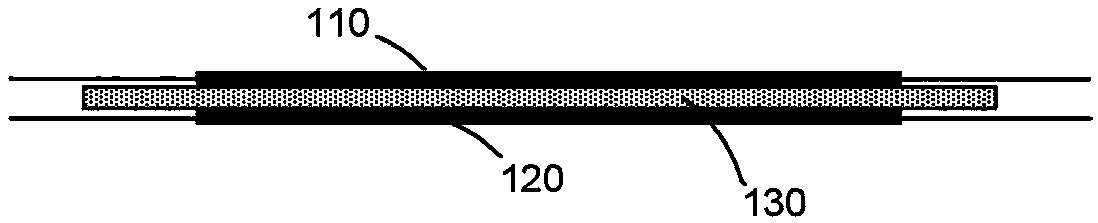

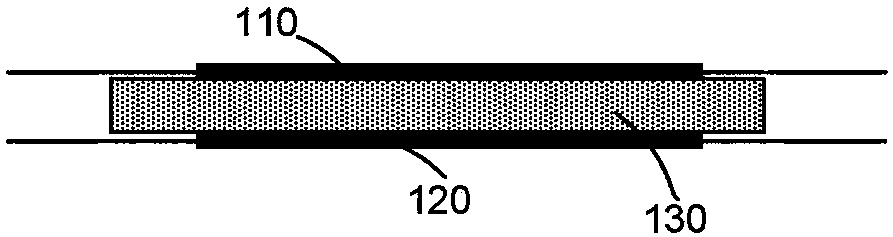

[0136] Figures 1A-1C Each shows a side view of a deformation sensing device with and without applied deformation in accordance with one or more embodiments.

[0137] Figures 1A-1C Each shows a side view of a deformation sensing device 100 (alternatively referred to herein as a deformation sensor 100 ). Figure 1A A side view of deformation sensing device 100 is shown without applied deformation, in accordance with one or more embodiments. like Figure 1A As shown, the deformation sensing device 100 includes a first strain gauge element 110 , a second strain gauge element 120 , and an elastic substrate 130 . The first strain gauge element 110 is formed on the first surface 130 - a of the elastic base 130 . The second strain gauge element is formed on the second surface 130-b of the elastic base 130, the second surface 130-b being opposite to the first surface 130-a.

[0138] The first strain gauge element 110 is configured to output a first signal in response to applied st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com