Multi-input-assembly-stage quick turn-off device and drive circuit thereof, and photovoltaic system

A driving circuit and multi-input technology, which is applied in the direction of output power conversion device, photovoltaic power generation, control/regulation system, etc., can solve the problems of application limitation, product size, driving power cost and unfavorable life, and achieve the goal of life and volume improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention, and should not be construed as limiting the present invention.

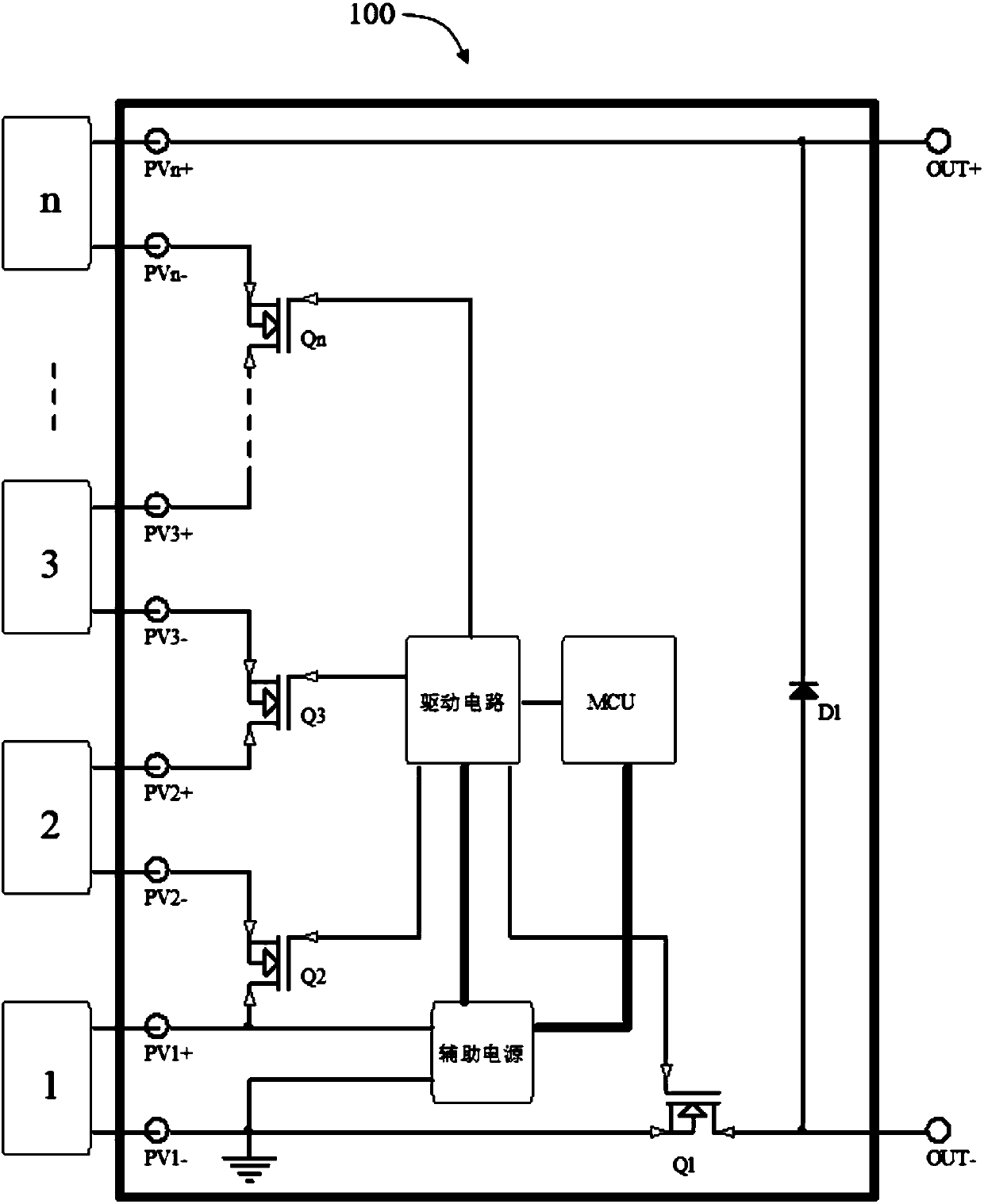

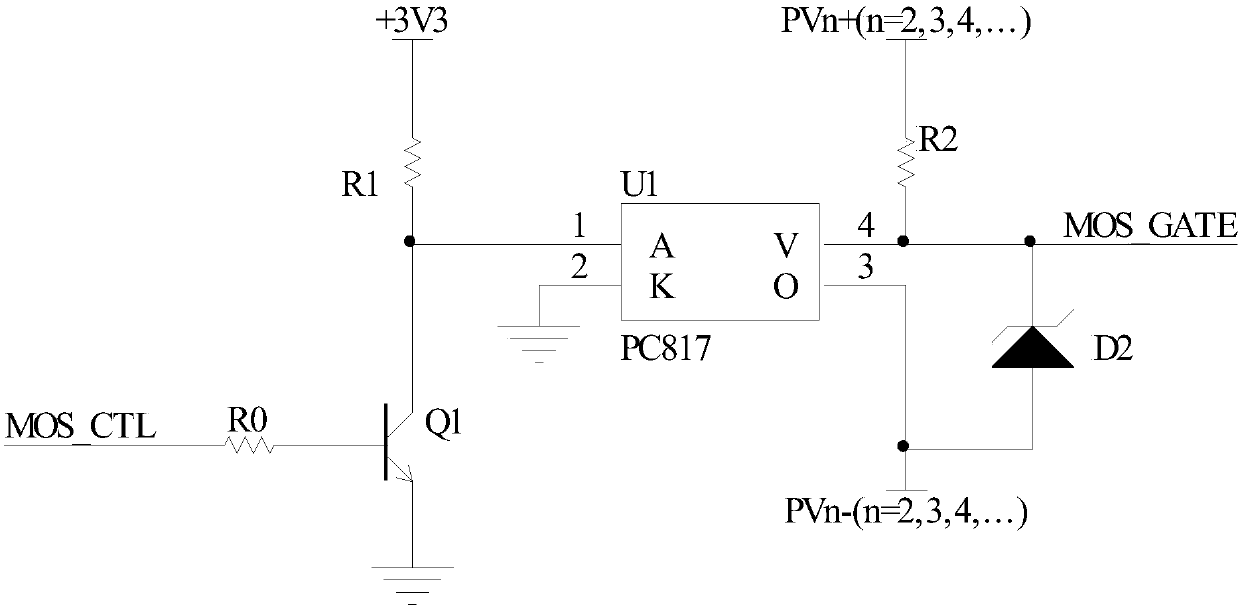

[0018] Please refer to Figure 1 to Figure 2 As shown, the present invention discloses a photovoltaic system, which includes n groups of photovoltaic modules connected in series, where n is greater than or equal to 2. Each group of photovoltaic modules has an input positive pole PVn+ and an input negative pole PVn-. In the photovoltaic system, a multi-input component-level rapid shutdown device 100 is also included.

[0019] see figure 1 As shown, the multi-input component-level rapid shutdown device 100 includes a control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com