A thermoelectric conversion method

A technology of thermoelectric conversion and thermoelectric current, which is applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, electrical components, etc. The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

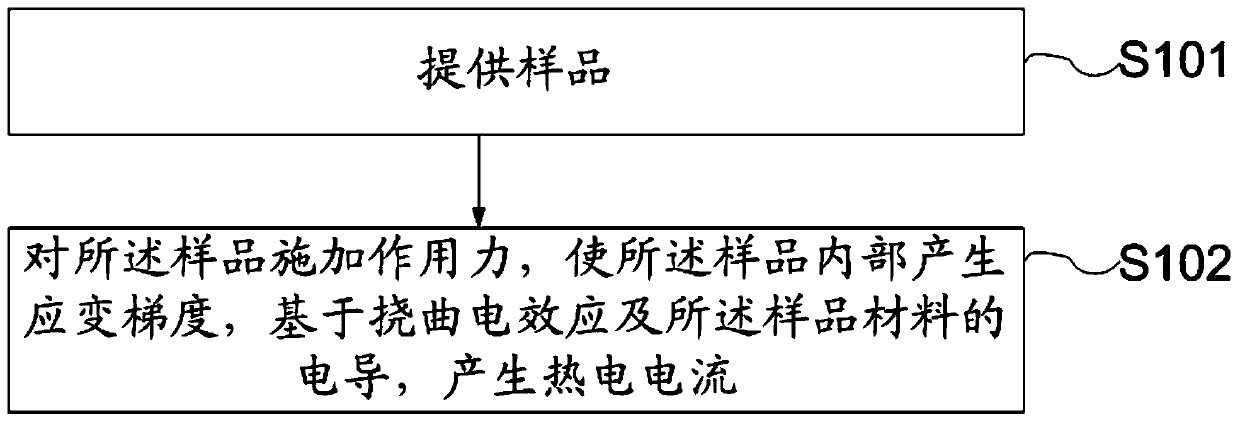

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

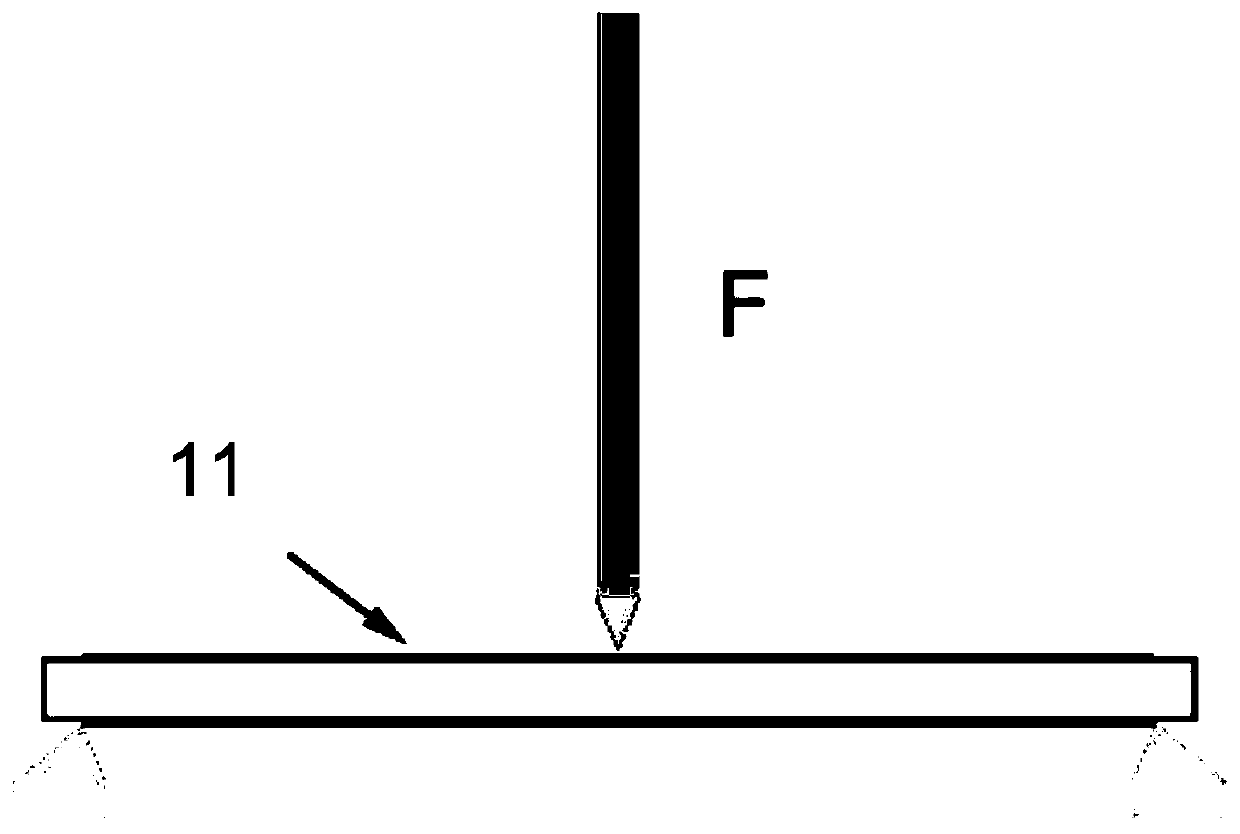

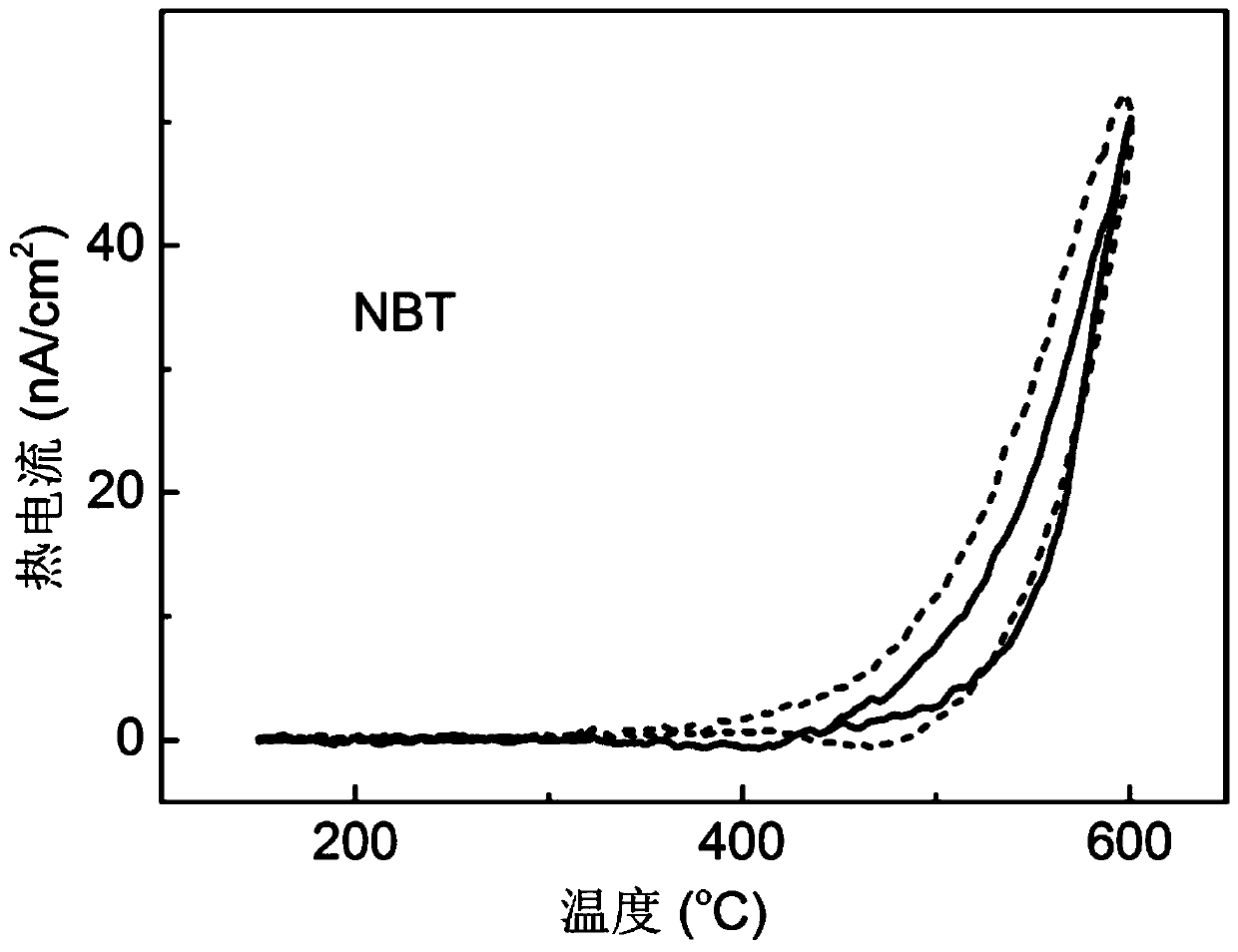

Embodiment Construction

[0026] As mentioned in the background technology section, the thermoelectric conversion methods in the prior art all limit the application scenarios of the thermoelectric conversion method and the use of materials capable of realizing thermoelectric conversion.

[0027] The inventors found that the reason for the above-mentioned problems in the prior art is that the thermoelectric conversion methods in the prior art all rely on special temperature environments, such as temperature gradients or variable temperature environments, and have relatively high requirements on the structure of the material itself. In the actual production process, thermoelectric conversion based on the Seebeck effect requires an additional system to obtain a temperature gradient, and the applicable materials for thermoelectric conversion based on the pyroelectric effect are limited, which limits the application of thermoelectric conversion.

[0028] Based on this, the present invention provides a thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com