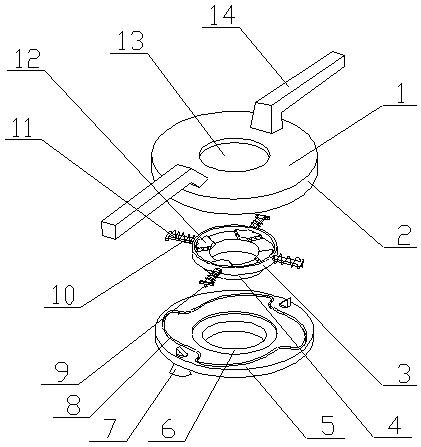

Water conservancy construction plugging cover dismounting device

A technology for dismantling devices and plugging caps, which is applied in the direction of manufacturing tools, pipe components, mechanical equipment, etc. It can solve the problems of large force required for disassembly, limited force arm of crossbar rotation, and influence on rotation disassembly, so as to ensure clamping The balance of stability and force, the force arm is labor-saving and efficient, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

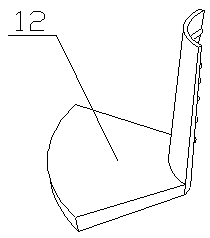

[0024] A water conservancy construction plugging cover removal device of the present invention is realized in the following way: when in use, the bearing (6) is put on the pipe port to restore the sponge, and the rubber on the sponge is attached to the pipe port, so that the plugging cover is positioned at the connection In the middle of the ring (3), hold the booster arm (14) with your hand, and then rotate the lower supporting plate (5), so that the wedge on the adjusting rod (7) passes over the inner gear plate (2), and at the same time, the lower supporting plate ( 5) The sliding groove (8) on the top drives the sliding pin to move, the sliding pin pushes the telescopic rod (10) to shrink inward, and the multiple clamping plates (12) shrink inward synchronously, and clamp the sealing cover from four directions Hold it so that the clamping point on the plugging cover is relatively balanced, and then reversely rotate the inner gear plate (2) through the wedge block, rotate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com