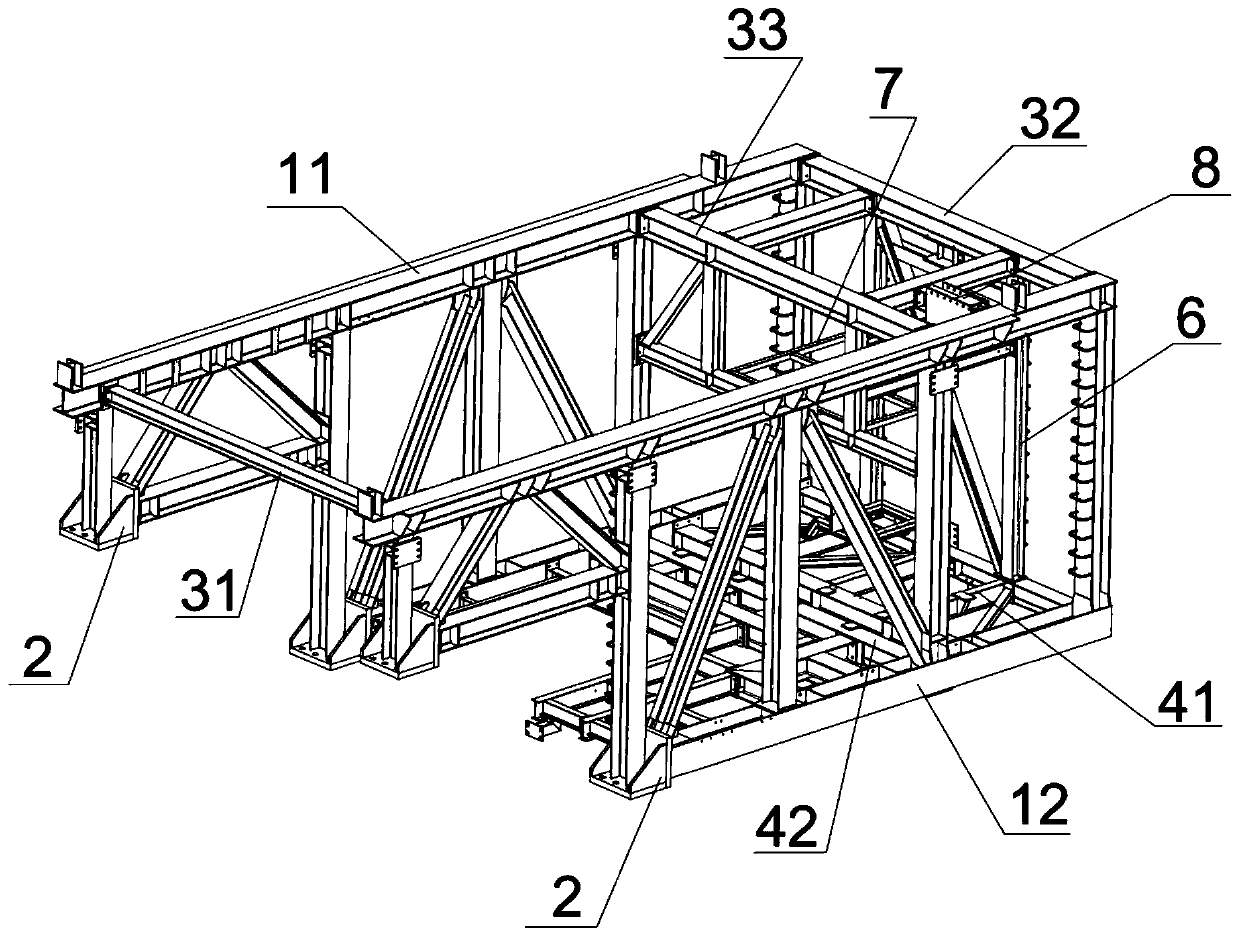

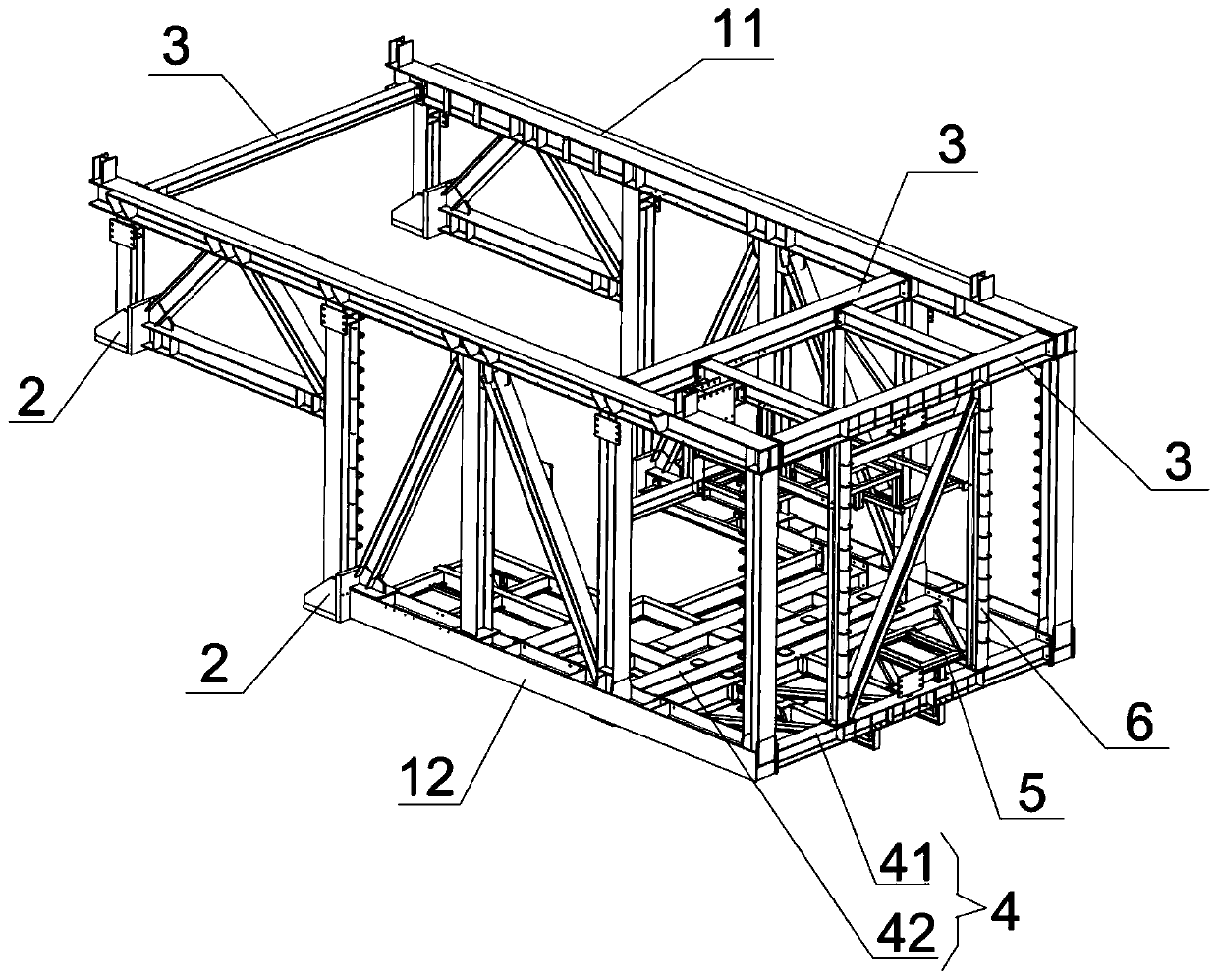

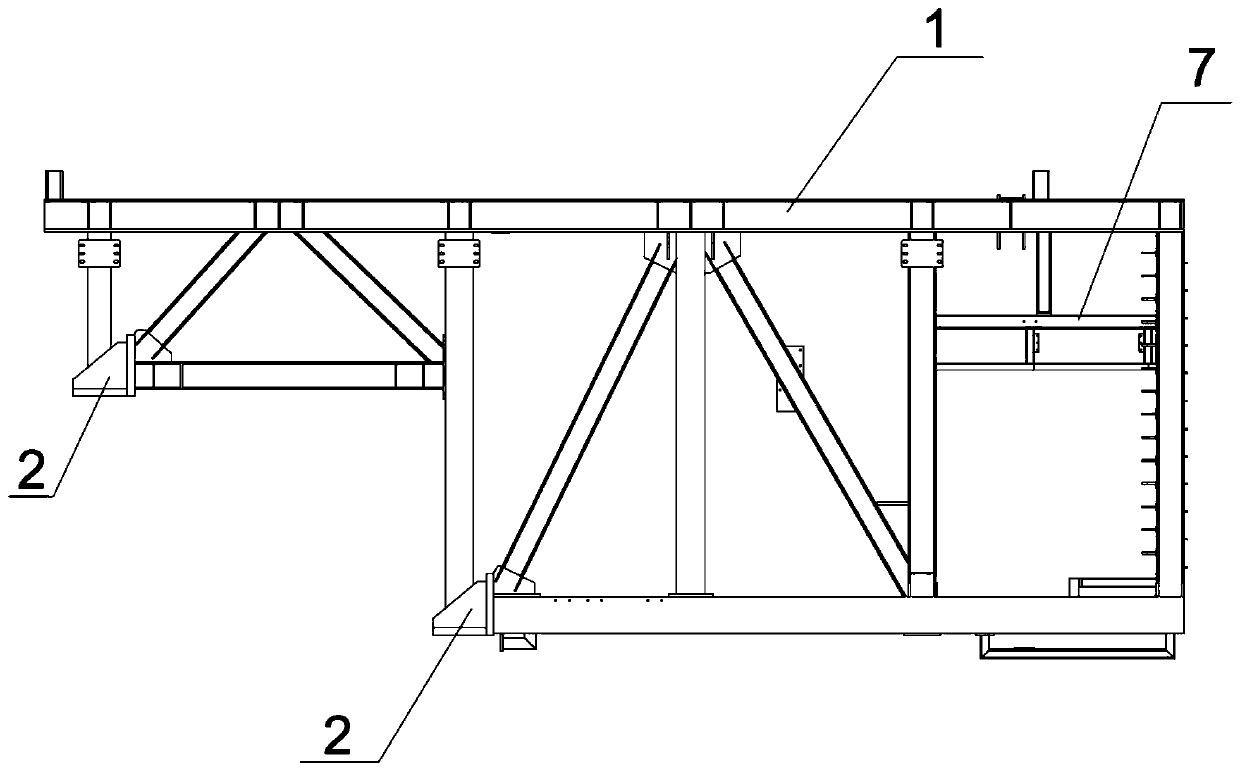

A large wind power generator rear frame and its production and assembly method

A wind turbine and rear frame technology, applied in the frame field, can solve the problems of high assembly accuracy requirements of profile components, inability to closely connect and cooperate with the front frame, difficulty in maintaining product assembly accuracy, etc., so that the three-dimensional structure is not easy to deform, Ease of standing and moving, three-dimensional structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] According to the rear frame structure of the large-scale wind power generator provided by the present invention, a rear frame product whose length, width and height are respectively 12350mm×5857mm×4977mm is produced, and the product is completed in the factory according to the production method provided by the present invention Parts were produced, then transported to the construction site for assembly, and finally successfully and accurately installed on the 5MW wind turbine.

[0054] The implementation results show that the large-scale wind generator rear frame provided by the present invention and its production and assembly method are successfully assembled at the installation site after multiple installations, disassembly, and transportation, which proves the feasibility of the processing and assembly scheme. It also has certain reference significance for the production and installation of other large assemblies in the future.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com