A method for simultaneous removal of nitrogen and phosphorus produced during sludge fermentation

A fermentation process and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as low acid production, difficult nitrogen and phosphorus removal, and damage to sludge dehydration performance , achieve the effect of improving dehydration performance, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

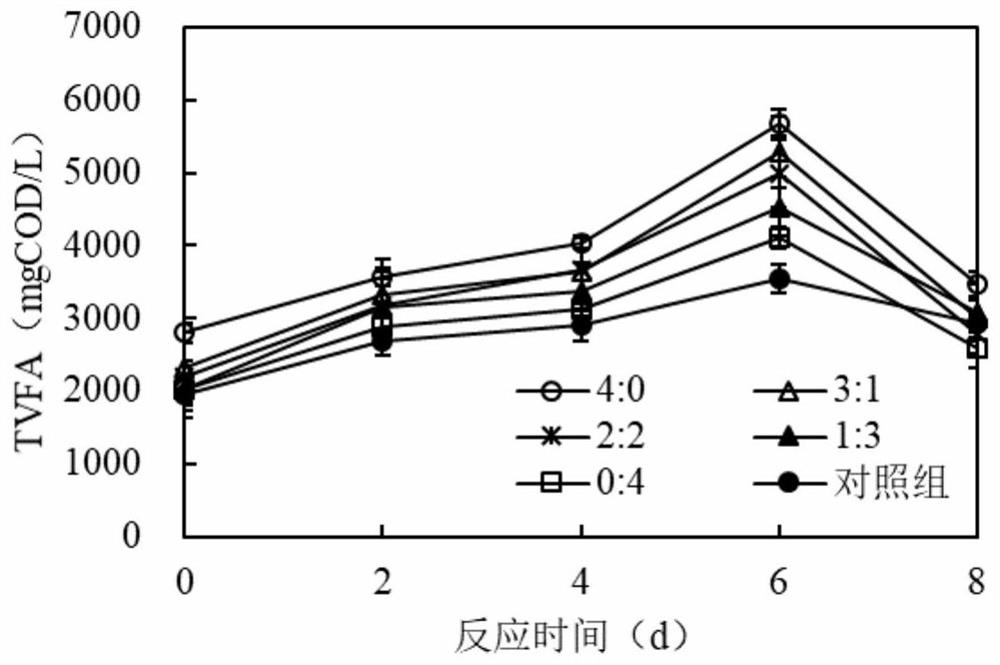

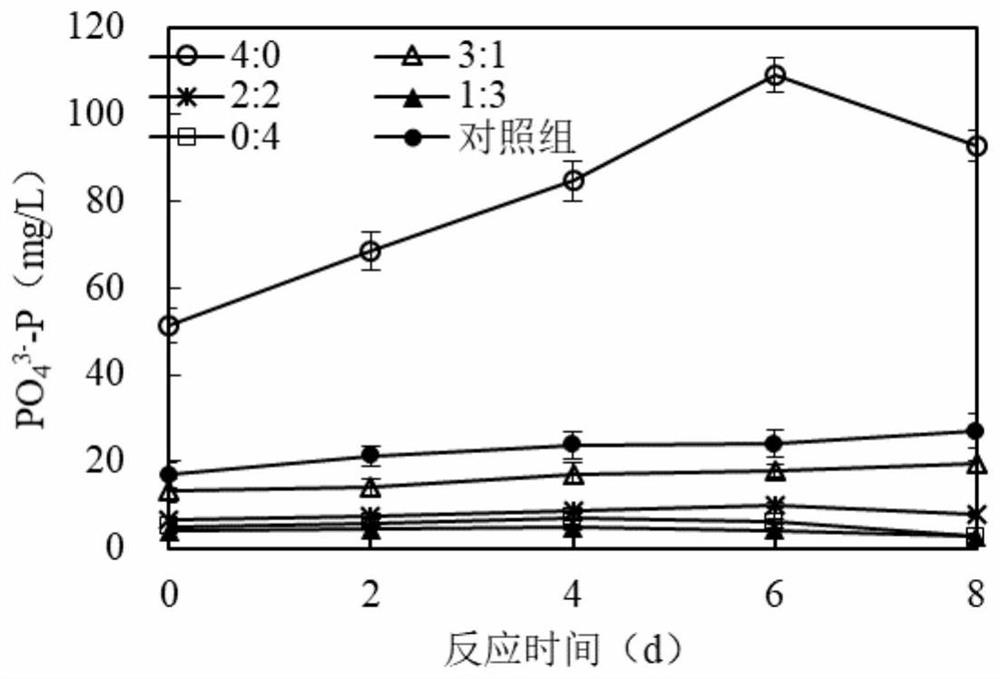

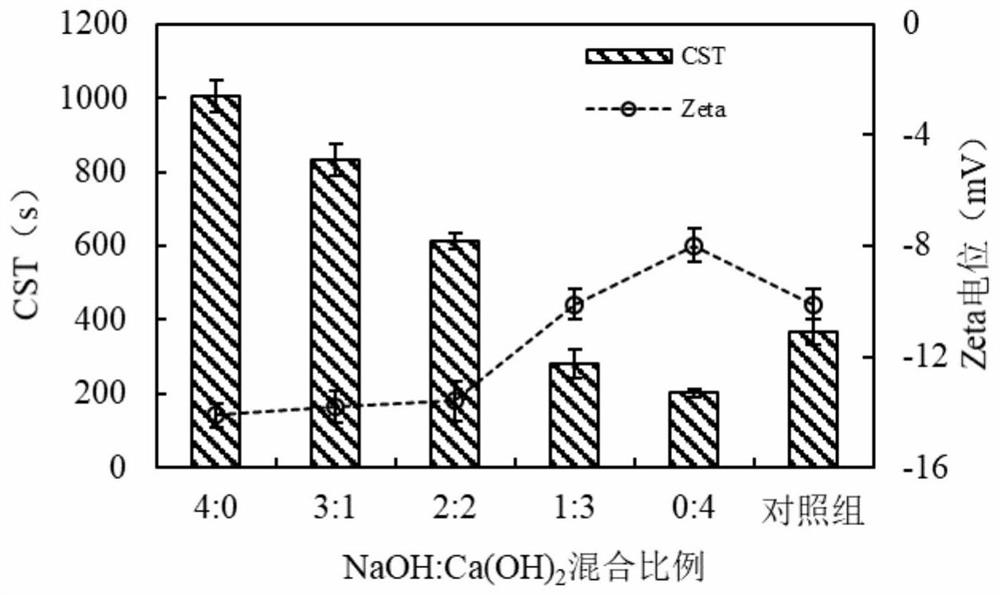

[0020] A method for synchronously removing nitrogen and phosphorus produced during sludge fermentation, comprising: using NaOH and Ca(OH) in the sludge fermentation process 2 The mixed alkali adjusts the pH value of the sludge, increases the acid production of the sludge, and reduces the PO in the fermentation broth. 4 3- -P content, improve the dehydration performance of sludge; at the same time, a certain amount of zeolite is added at one time before fermentation, which reduces the NH in the fermentation process 4 + -N, and further improve the sludge dewatering performance.

[0021] Put the sieved primary sludge in a screw-top glass bottle, and use 2mol / L NaOH and 1mol / L Ca(OH) 2 The lye, according to NaOH and Ca(OH) 2 The molar ratio was 4:0, 3:1, 2:2, 1:3 and 0:4 for mixing, and the pH value of each group of sludge was adjusted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com