Sn-GAC particle, and application thereof in three-dimensional electrochemical reaction treatment of 4-chlorophenol wastewater

A technology of chemical reaction and three-dimensional electricity, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of limited removal rate, difficult removal, high removal cost, etc., to achieve complete degradation and no The effect of secondary pollution and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

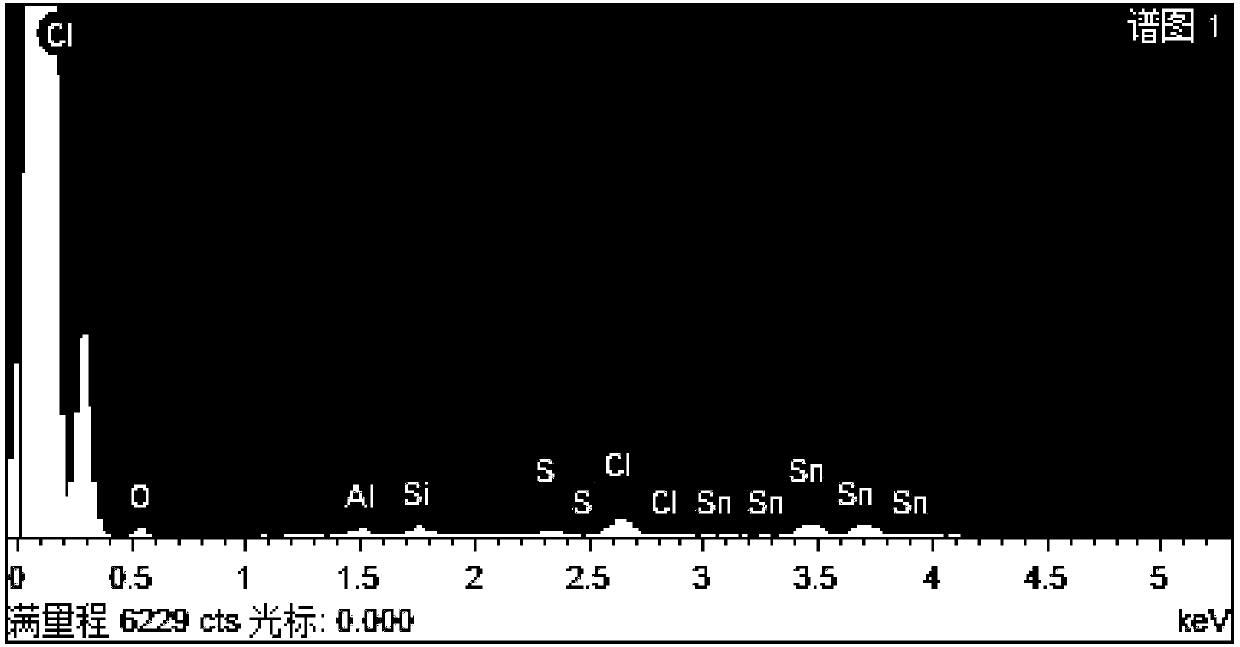

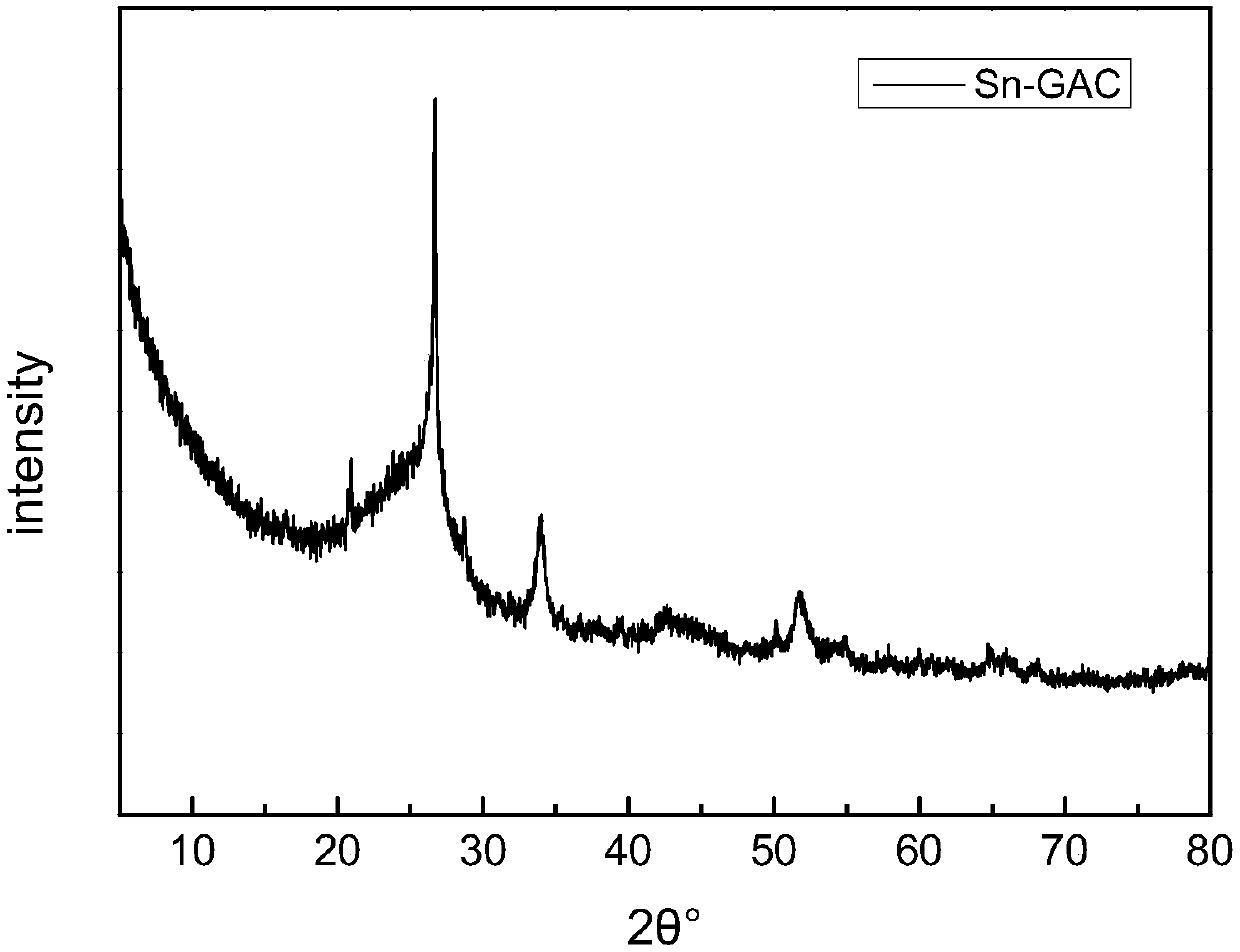

[0029] (1) Pretreatment of granular activated carbon: boil the granular activated carbon with a large amount of deionized water, dry it, and set aside.

[0030] (2) According to the mass ratio: 1:6. Weigh the SnCl in turn 4 ·5H 2 O and GAC.

[0031] (3) SnCl 4 ·5H 2O is dissolved in an organic alcohol solvent to obtain a mixed solution, and then GAC is soaked in the mixed solution, shaken at 150r / min for 2 hours, and the crude product of the supported Sn-GAC particles is obtained, and then dried and roasted at 300°C to obtain the supported Sn-GAC particles. Sn–GAC particles.

preparation Embodiment 2

[0033] (1) Pretreatment of granular activated carbon: boil the granular activated carbon with a large amount of deionized water, dry it, and set aside.

[0034] (2) According to the mass ratio: 1:7. Weigh the SnCl in turn 4 ·5H 2 O and GAC.

[0035] (3) SnCl 4 ·5H 2 O was dissolved in an organic alcohol solvent to obtain a mixed solution, and then GAC was soaked in the mixed solution, and shaken at 175r / min for 4 hours to obtain the crude product of supported Sn-GAC particles, which was then dried and calcined at 400°C to obtain the supported Sn-GAC particles. Sn–GAC particles.

preparation Embodiment 3

[0037] (1) Pretreatment of granular activated carbon: boil the granular activated carbon with a large amount of deionized water, dry it, and set aside.

[0038] (2) According to the mass ratio: 1:8. Weigh the SnCl in turn 4 ·5H 2 O and GAC.

[0039] (3) SnCl 4 ·5H 2 O is dissolved in an organic alcohol solvent to obtain a mixed solution, and then GAC is soaked in the mixed solution, shaken at 200r / min for more than 6 hours, and the crude product of supported Sn-GAC particles is obtained, and then dried and roasted at 500°C to obtain the loaded type Sn–GAC particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com