Integrated cut and imprinted sliding double-layer packing box and anti-counterfeit packing method

An all-in-one, packaging box technology, applied in packaging, transportation and packaging, and devices to prevent repeated filling of containers, etc., can solve the loss of non-commercial behavior reuse value, the high cost of passive RFID technology, and the laborious opening of product users. and other problems, to achieve the effect of avoiding repeated packaging, convenient use and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

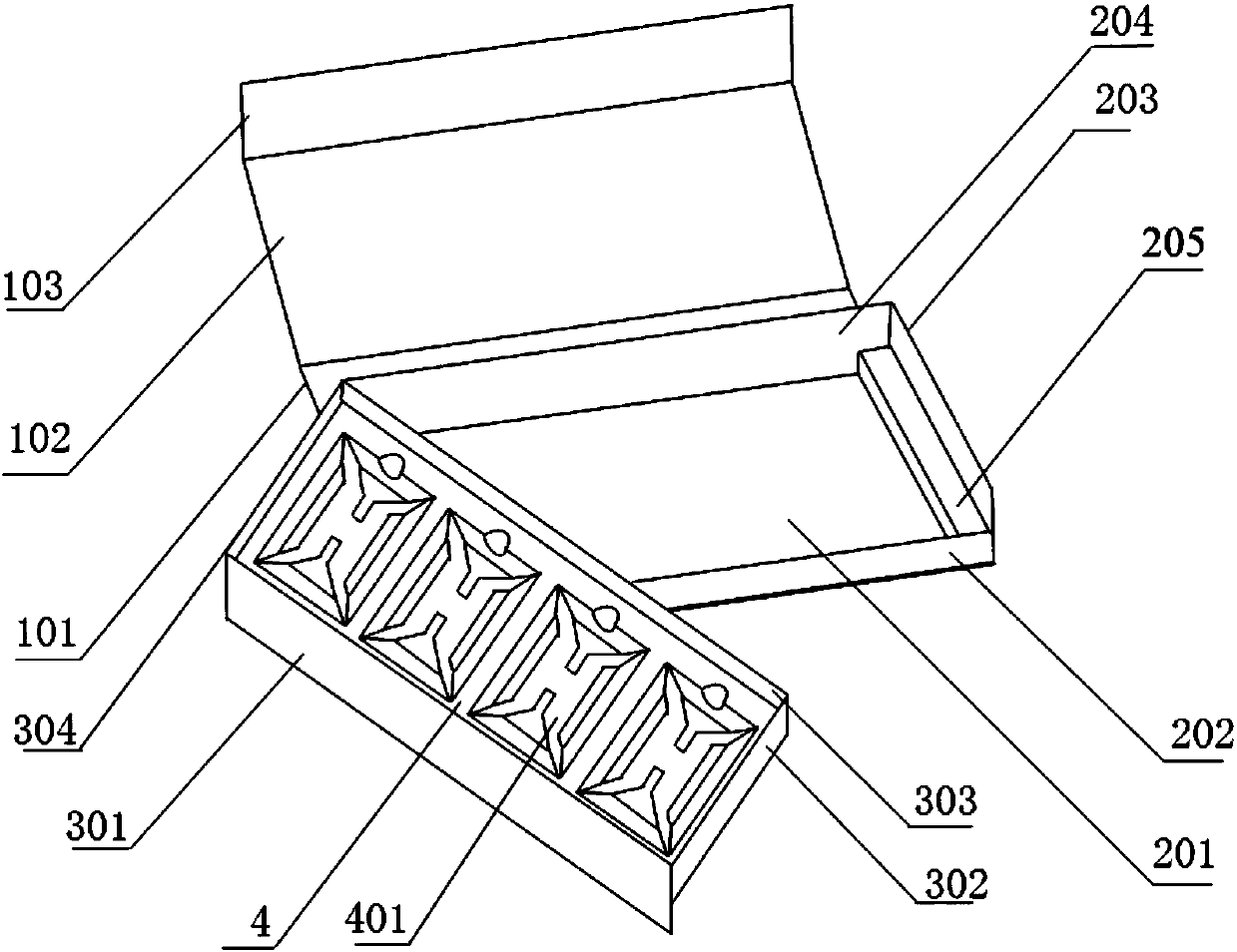

[0027] The invention provides a sliding double-layer packaging box with integrated cutting and embossing, referring to figure 1 , including a box body and a box cover, the box body is composed of a bottom plate 201, a front plate 202, a side plate 203 and a rear plate 204, and the sides of the front plate 202, the side plates 203 and the rear plate 204 are successively connected, and the front The bottom edge of plate 202, side plate 203 and back plate 204 is respectively fixed on three limits of base plate 201, wherein the height of side plate 203 is identical with back plate 204, and the height of front plate 202 is less than the height of back plate 204; There is an inner box, and the inner box is composed of an inner box bottom plate, an inner box front plate 301, a first inner box side plate 302, an inner box rear plate 303 and a second inner box side plate 304, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com