Plastic preservative film with high CO2/O2 permeation ratio and preparation method

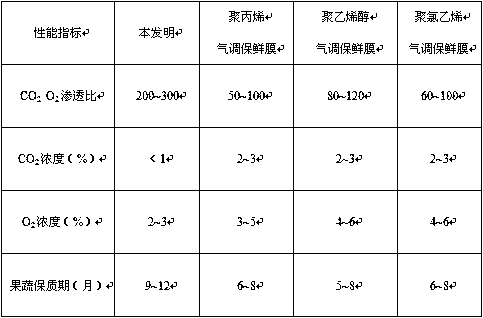

A fresh-keeping film and high-permeability technology, applied in the field of fresh-keeping materials, can solve the problems that fruits and vegetables are easily damaged by carbon dioxide, cannot effectively maintain the concentration ratio, and the shelf life of fruits and vegetables is short, and achieve good economic advantages, obvious effect of air conditioning, and long shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The specific process for the preparation of mixed colloids is:

[0036] First add polyvinyl alcohol into ethanol, soak for a period of time, then filter and dry, then add deionized water and heat and stir to obtain polyvinyl alcohol colloid, then use propylene carbonate as carbon dioxide adsorbent, add propylene carbonate In the polyvinyl alcohol colloid, stir until it is evenly mixed to obtain a mixed colloid; the soaking time is 13 hours; the heating temperature is 55°C;

[0037] In the mixed colloid, the total mass parts of each component are calculated in 100 parts, including: 25 parts of polyvinyl alcohol, 50 parts of deionized water, and 25 parts of propylene carbonate;

[0038] (2) The specific process of preparation of colloid / polyethylene composite film is as follows:

[0039]Take a polyethylene film with a microporous structure, and use the whole board coating machine to evenly coat the prepared mixed colloid on the surface of the film to obtain a colloid...

Embodiment 2

[0044] (1) The specific process for the preparation of mixed colloids is:

[0045] First add polyvinyl alcohol into ethanol, soak for a period of time, then filter and dry, then add deionized water and heat and stir to obtain polyvinyl alcohol colloid, then use propylene carbonate as carbon dioxide adsorbent, add propylene carbonate In the polyvinyl alcohol colloid, stir until it is evenly mixed to obtain a mixed colloid; the soaking time is 12 hours; the heating temperature is 50°C;

[0046] In the mixed colloid, the total mass parts of each component are calculated in 100 parts, including: 20 parts of polyvinyl alcohol, 60 parts of deionized water, and 20 parts of propylene carbonate;

[0047] (2) The specific process of preparation of colloid / polyethylene composite film is as follows:

[0048] Take a polyethylene film with a microporous structure, and use the whole board coating machine to evenly coat the prepared mixed colloid on the surface of the film to obtain a colloi...

Embodiment 3

[0053] (1) The specific process for the preparation of mixed colloids is:

[0054] First add polyvinyl alcohol into ethanol, soak for a period of time, then filter and dry, then add deionized water and heat and stir to obtain polyvinyl alcohol colloid, then use propylene carbonate as carbon dioxide adsorbent, add propylene carbonate In the polyvinyl alcohol colloid, stir until it is evenly mixed to obtain a mixed colloid; the soaking time is 15 hours; the heating temperature is 60°C;

[0055] In the mixed colloid, the total mass parts of each component is calculated in 100 parts, wherein: 30 parts of polyvinyl alcohol, 40 parts of deionized water, 30 parts of propylene carbonate;

[0056] (2) The specific process of preparation of colloid / polyethylene composite film is as follows:

[0057] Take a polyethylene film with a microporous structure, and use the whole board coating machine to evenly coat the prepared mixed colloid on the surface of the film to obtain a colloid / polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com