Screw tightening assembly and tightening device

A component and screw technology, applied in the field of screw tightening components and tightening devices, can solve problems such as inconvenience, deformation, and no support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

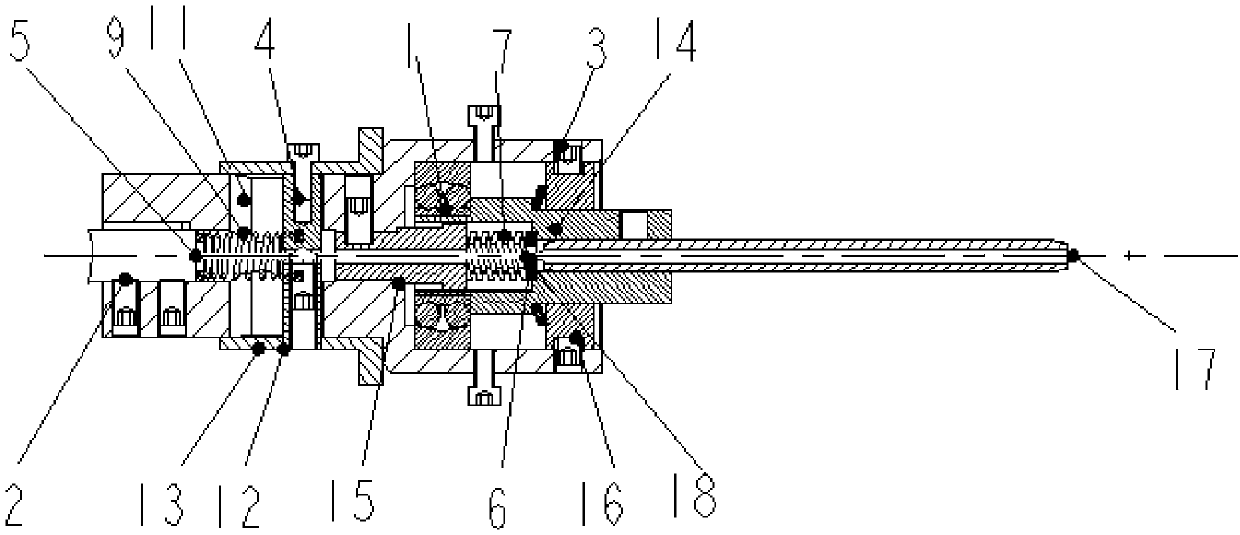

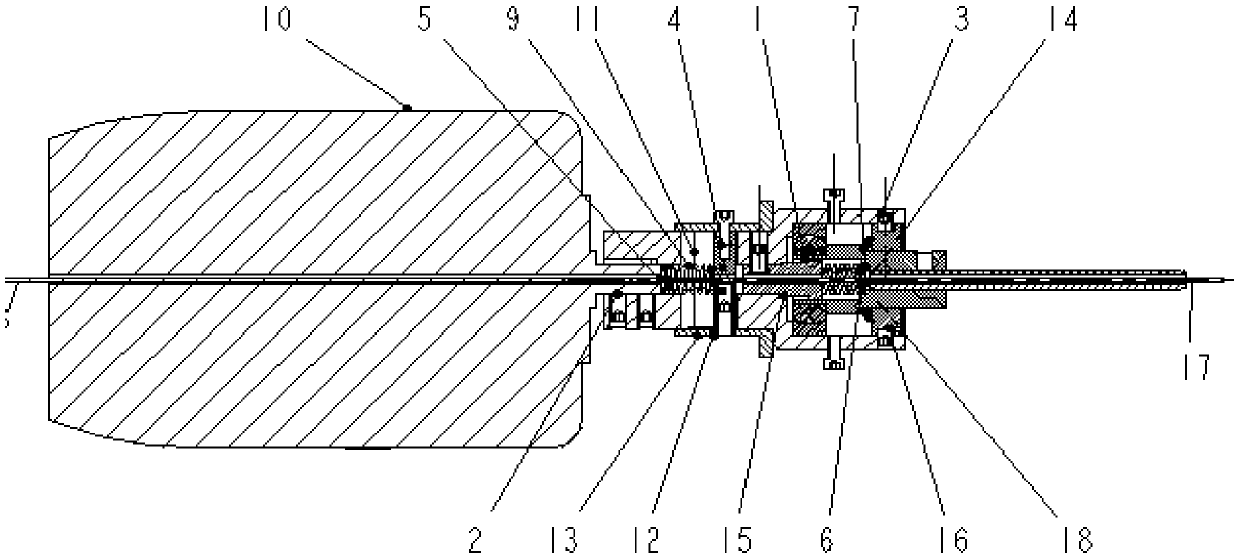

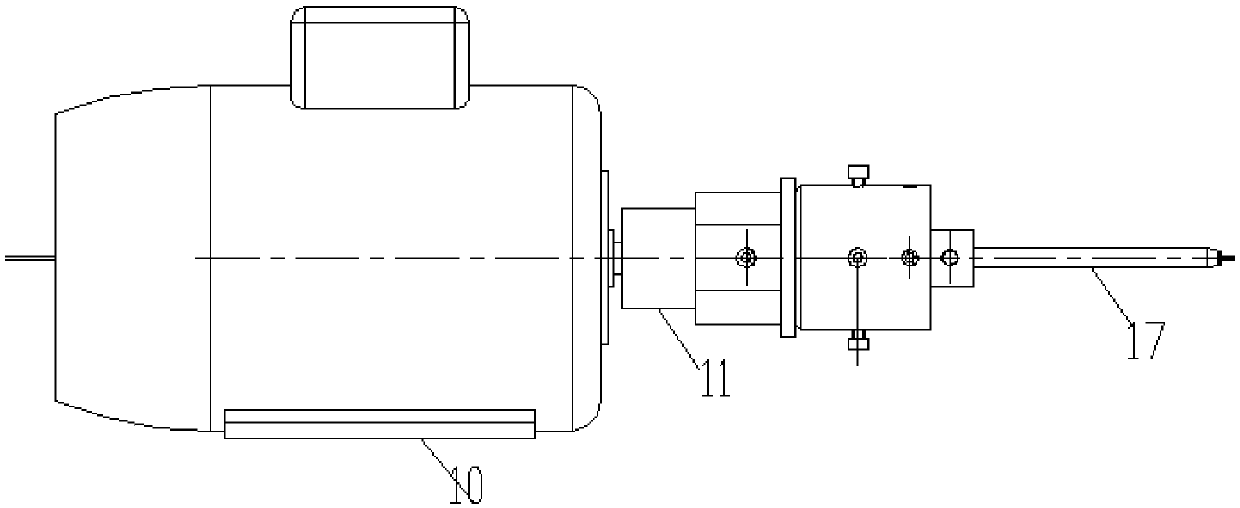

[0039] figure 1 A schematic diagram of the internal structure of the screw tightening assembly provided in Embodiment 1 of the present invention; figure 2 A schematic diagram of the internal structure of the screw tightening assembly and the motor provided in Embodiment 1 of the present invention; image 3 A schematic diagram of the external structure of the motor in the screw tightening assembly provided by Embodiment 1 of the present invention.

[0040] like Figure 1 to Figure 3 As shown, the screw tightening assembly provided by the embodiment of the first aspect of the present invention includes a transition shaft 11, a fixed shaft 14 and a screwdriver 17, a groove is arranged in the transition shaft 11, and the fixed shaft 14 is arranged in the concave In the groove, the screwdriver 17 is arranged in the fixed shaft 14 , and the self-aligning ball bearing 1 is arranged between the fixed shaft 14 and the transition shaft 11 .

[0041] In the screw tightening assembly ...

Embodiment 2

[0053] The shape of the cutter head 21 of the existing screwdriver 17 is a right-angle transition. When the locking process is carried out, the cutter head 21 will cause wear to the screw head, and the right angle will cause stress concentration, and the stress concentration will cause fatigue failure, reducing the use of the screwdriver 17. life.

[0054] like Figure 4 As shown, in any of the above technical solutions, further, the screwdriver 17 includes a knife shaft 20 and a knife head 21, and the knife shaft 20 and the knife head 21 transition through a slope.

[0055] The geometrical transition of the bit 21 of the screw is rounded, which improves the stress concentration, improves the service life of the screwdriver 17, and reduces the damage to the screw head during work.

[0056] In any of the above technical solutions, further, there are multiple cutter heads 21 , which are respectively arranged on the cutter bar 20 . And the screwdriver 17 is made into a double-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com