Liquid guide device and method for stable flow control in semi-continuous casting process of magnesium alloy

A magnesium alloy, semi-continuous technology, applied in the field of casting, can solve the problems of uneven outflow of high-temperature melt, affecting the effect of melt shunting, and changing the liquid level of the crystallizer. tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

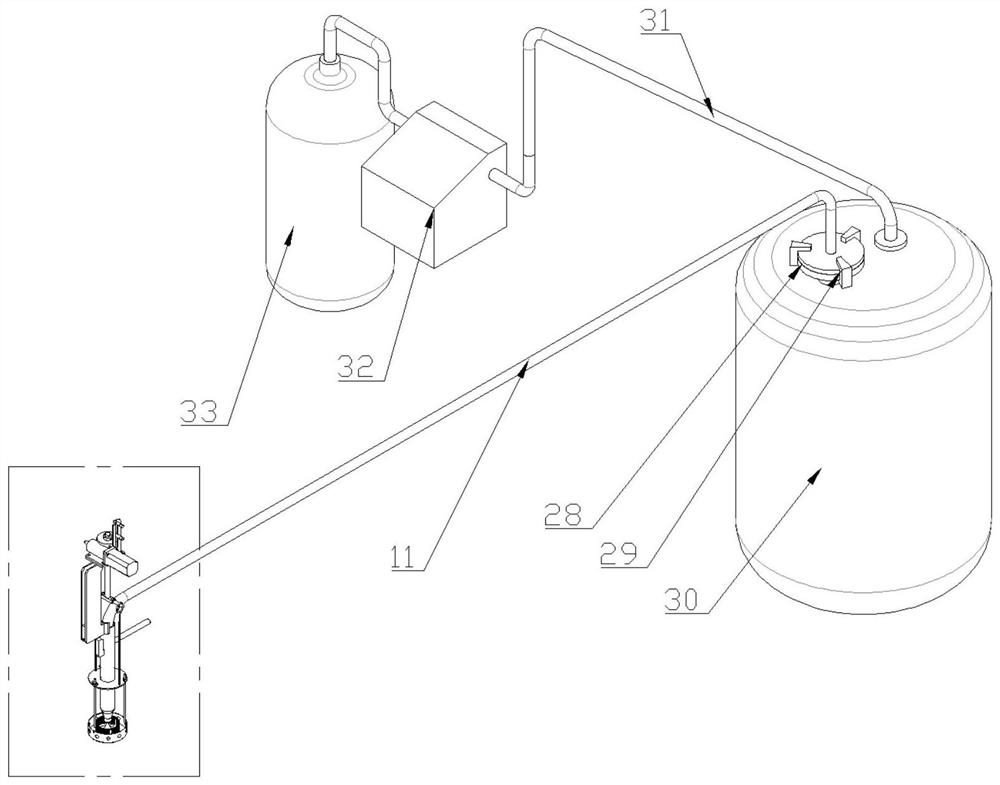

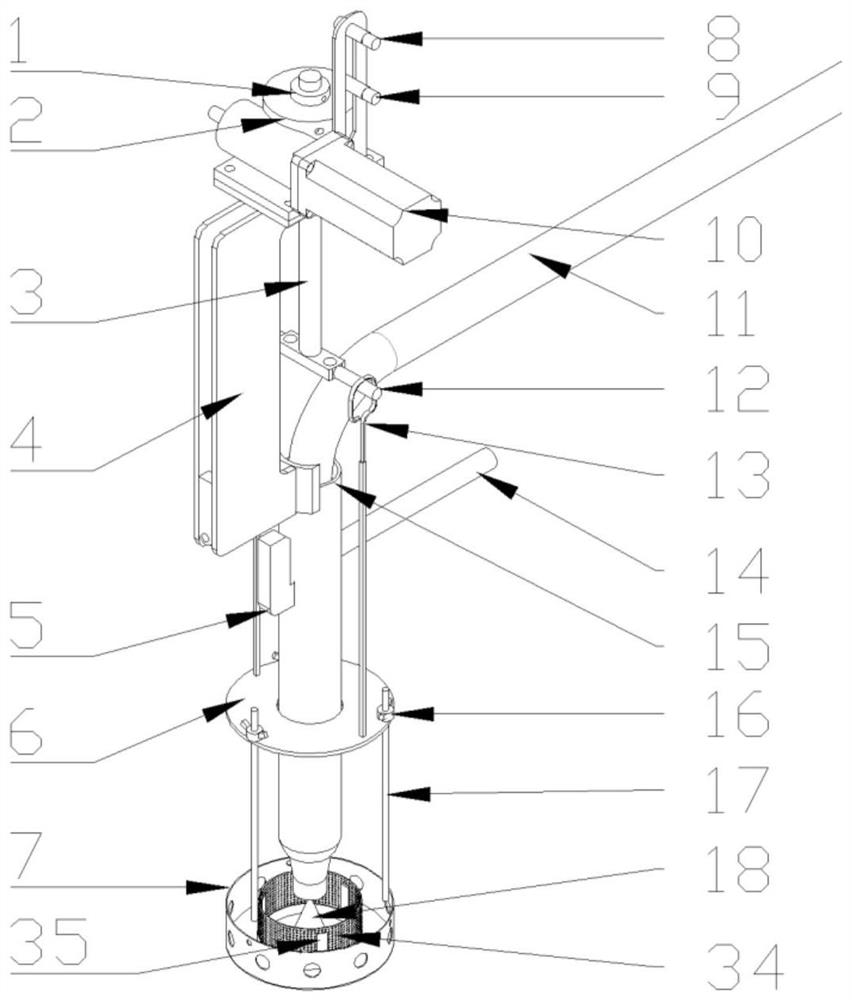

[0072] A liquid guide device for stable flow control in the semi-continuous casting process of magnesium alloys, the schematic diagram of which is shown in figure 1 , in the semi-continuous casting, comprise the crucible 30 that is filled with magnesium alloy, guide tube 11, crystallizer, guide tube 11 is square hook shape, is divided into short end (inlet end), long end (outlet end) and the middle liquid guide main pipe; the outer side of the liquid guide tube is welded with a stainless steel sleeve slightly larger than the diameter of the guide tube, and the liquid guide tube extends to the crucible 30 filled with magnesium alloy, and the port is located below the magnesium alloy. The liquid inlet end of the catheter is sealed by the sealing flange 28 and the crucible, and fixed by the concave buckle 29; A protective gas control device 32 is arranged on the top, and the protective gas control device 32 is used to control the internal pressure of the crucible by adjusting the...

Embodiment 2

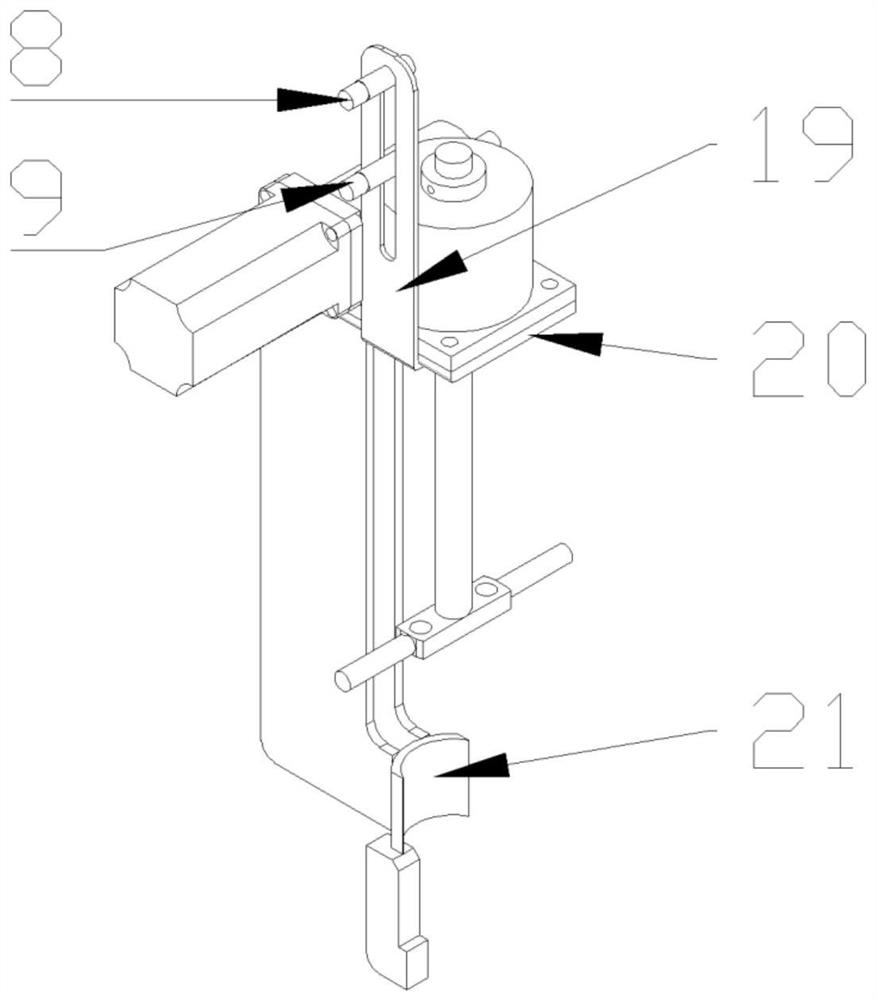

[0090] A liquid guiding device for stabilizing and controlling flow in the semi-continuous casting process of magnesium alloys in this embodiment is the same as that in Embodiment 1, except that the hanging beam adjustment part used is a manual hanging beam adjusting part, and the liquid guiding control actuator Partial enlarged picture is Figure 4 , the difference is:

[0091] The lifting device in the liquid guiding control executive mechanism includes the quick-hanging support arm 4, the hanging beam 12, the positioning block 21, the lifting rod 3 and the manual hanging beam adjusting part, and the manual hanging beam adjusting part includes a fine-tuning bolt 22, an adjusting rod 23, a shaft Pin 24, steel block 38, fast-falling pad iron 25, fast-falling pad iron nut 26, fast-falling pad iron screw rod 27; the adjusting rod 23 is connected with the quick-hanging support arm 4 through the pivot pin 24, and one end of the adjusting rod 23 is a suspension The beam 12 and the...

Embodiment 3

[0096] Embodiment 1 of the present invention is an electric liquid guiding device with a rectangular shunt tank, and its control shunting device is as follows: Figure 5 shown.

[0097] In this embodiment, a liquid guiding device for stabilizing and controlling flow in the semi-continuous casting process of magnesium alloys is provided with a liquid guiding control actuator and a protective gas control device at the liquid outlet of the catheter tube. The liquid guiding control actuator can be divided into electric guiding The liquid control device and the manual liquid control device; the electric liquid control device uses the motor and the limit switch to realize the liquid control; the manual liquid control device is slightly different from the electric liquid control device, and the lever principle is used to realize the liquid control;

[0098] This embodiment is an electric catheter control device. In this embodiment, the catheter is in the shape of a square hook, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com