A method for preparing copper anti-fouling micro-nano composite structure layer by electric discharge machining

A micro-nano composite structure and EDM technology, which is applied in the field of material surface engineering, can solve the problems of pollution secondary dirt deposition, affecting service life, thermal conductivity is not as good as thermal conductivity, etc., to reduce pollution, reduce additional expenses, EDM Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

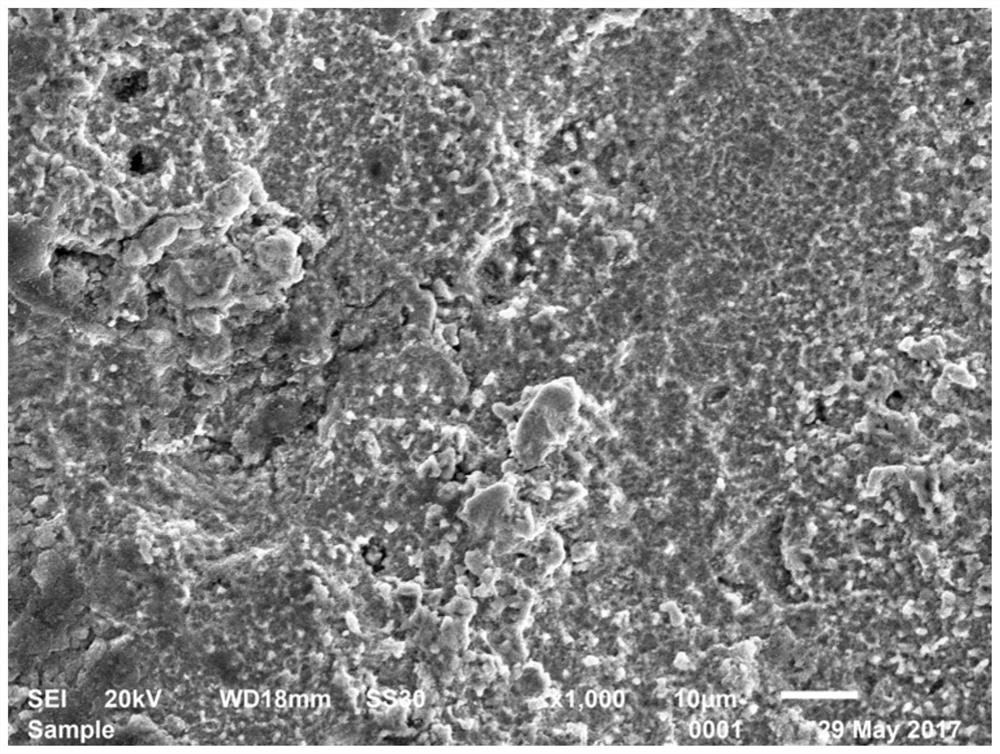

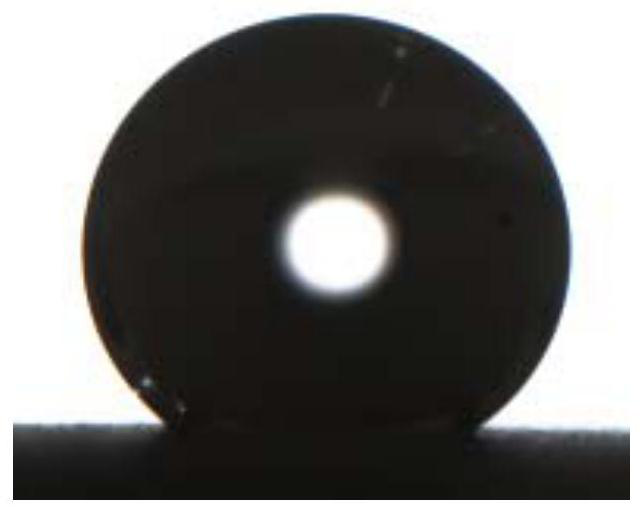

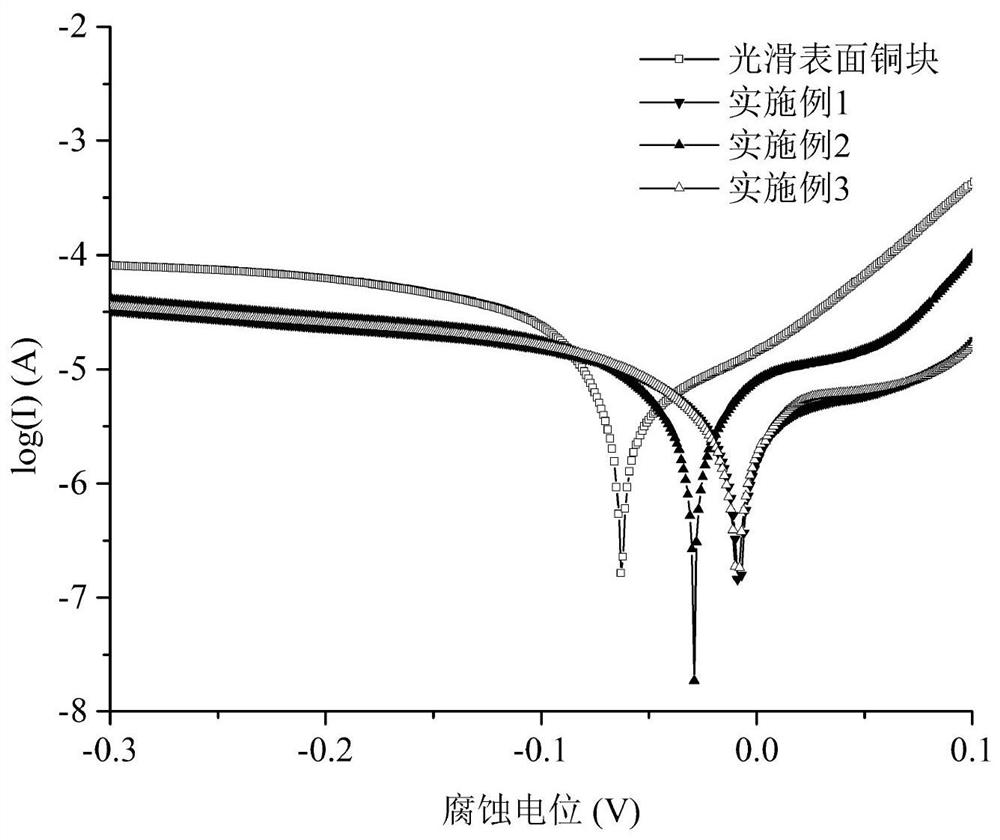

Embodiment 1

[0029] First, cut the copper block sample with a size of 10mm×10mm×3mm, and polish the surface of the cut copper block with 200, 400, and 600 mesh sandpaper to remove impurities and scale on the surface, and then use acetone and absolute ethanol to Ultrasonic cleaning with deionized water for 5 minutes to remove the residual abrasive debris on the surface, and then dry the copper block with a blower; secondly, install the copper block on the fixture of the EDM machine to ensure that the copper block is installed correctly and can conduct electricity without In case of short circuit, adjust the injection direction of the EDM fluid to point to the surface of the copper block, and adjust the injection direction to form an angle of about 10° with the surface of the copper block. Set the EDM parameters as follows: current 20A, pulse width 100μs, duty cycle 80% , Gap voltage 40V, processing depth 1mm, and then start processing; when the EDM reaches the set depth, the surface of the p...

Embodiment 2

[0031] First, cut the copper block sample with a size of 10mm×10mm×3mm, and polish the surface of the cut copper block with 200, 400, and 600 mesh sandpaper to remove impurities and scale on the surface, and then use acetone and absolute ethanol to Ultrasonic cleaning with deionized water for 5 minutes to remove the residual abrasive debris on the surface, and then dry the copper block with a blower; secondly, install the copper block on the fixture of the EDM machine to ensure that the copper block is installed correctly and can conduct electricity without In the case of short circuit, adjust the injection direction of the EDM fluid to point to the surface of the copper block, and adjust the injection direction to form an angle of about 10° with the surface of the copper block. Set the EDM parameters as follows: current 15A, pulse width 80μs, duty cycle 80% , Gap voltage 40V, processing depth 1mm, and then start processing; when the EDM reaches the set depth, the surface of th...

Embodiment 3

[0033] First, cut the copper block sample with a size of 10mm×10mm×3mm, and polish the surface of the cut copper block with 200, 400, and 600 mesh sandpaper to remove impurities and scale on the surface, and then use acetone and absolute ethanol to Ultrasonic cleaning with deionized water for 10 minutes to clean off the residual wear debris on the surface, and then dry the copper block with a blower; secondly, install the copper block on the fixture of the EDM machine to ensure that the copper block is installed correctly. There is no short circuit in the conduction, adjust the injection direction of the EDM fluid to point to the surface of the copper block, and adjust the injection direction to form an angle of about 10° with the surface of the copper block. Set the EDM parameters as follows: current 18A, pulse width 100μs, duty cycle 80%, gap voltage 40V, processing depth 2mm, and then start processing; when the EDM reaches the set depth, the surface of the processed sample i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| aniline point | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com