Internal cleaning system of dedusting pipeline

A cleaning system and pipeline technology, applied in the field of mechanical equipment, can solve the problems of affecting the dust removal effect of the dust removal pipeline, the dust removal pipeline is easy to consolidate and adhere to block dust, and it is difficult to remove block dust, so as to reduce the workload of operation and maintenance and ensure Airtightness and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a system for cleaning the interior of the dust removal pipeline, which cleans the dust inside the dust removal pipeline 1. The dust removal pipeline 1 is the dust transmission pipeline in the dust removal system, and the dust removal system is stainless steel slag processing, etc. Dust treatment method, dust removal equipment used in the device.

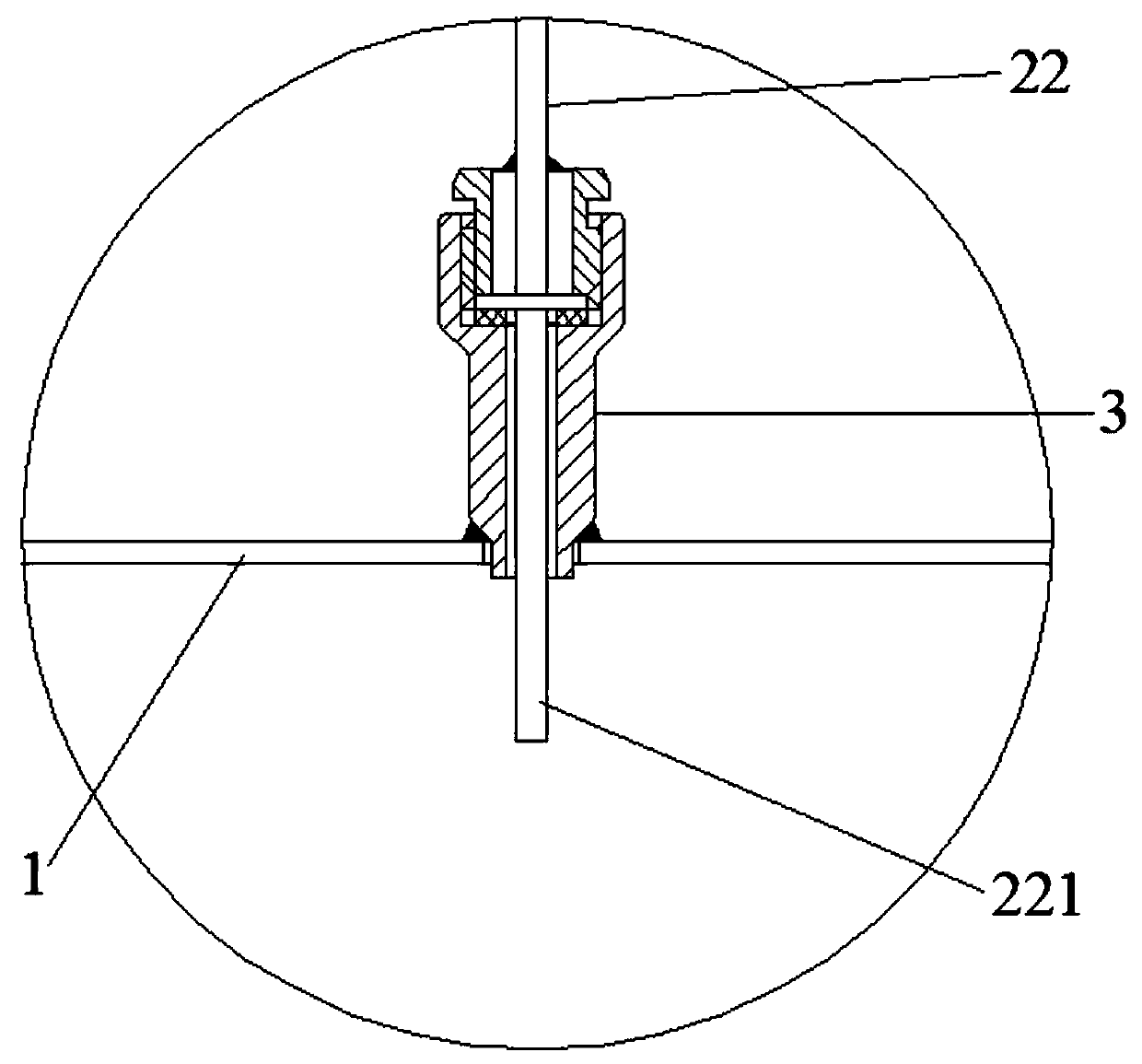

[0035] Please refer to figure 1 , is a structural schematic diagram of a blowing unit in the dust removal pipeline internal cleaning system provided by the present invention, wherein a dust removal pipeline internal cleaning system includes at least one blowing unit 2 distributed on the dust removal pipeline 1; the blowing unit 2 is connected to A high-pressure air source, wherein the blowing unit includes at least one blowing nozzle 221 , and the blowing nozzle 221 of the blowing unit 2 passes through the pipe wall of the dust removal pipeline 1 and enters the inside of the dust removal pipeline 1 . ...

Embodiment 2

[0056] This embodiment is described based on the content of Embodiment 1, therefore, similar components are denoted by similar reference numerals.

[0057] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the cleaning system includes three sets of blowing units 2, and the three sets of blowing units 2 are separated along the extension of the dust removal pipeline 1 according to a certain distance. The direction is distributed on the dust removal pipeline 1, and the distance between the adjacent spray units 2 can be set according to the length of the dust removal pipeline 1, for example, in the middle of the dust removal pipeline 1, a The above-mentioned blowing unit starts from the middle part of the dust removal pipeline 1, extends to both ends for a certain distance, and then installs the remaining two groups of blowing units 2, so that the three sets of blowing units 2 can cover the dust removal pipeline to avoid cleaning. out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com