Wood crushing vehicle

A technology for shredding vehicles and wood, applied in the direction of wood processing equipment, grain processing, manufacturing tools, etc., can solve the problems of inability to meet the feeding of the shredder, the production efficiency cannot be improved, and the collection and packaging are inconvenient, and meet the requirements of low noise and installation. The effect of low height and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

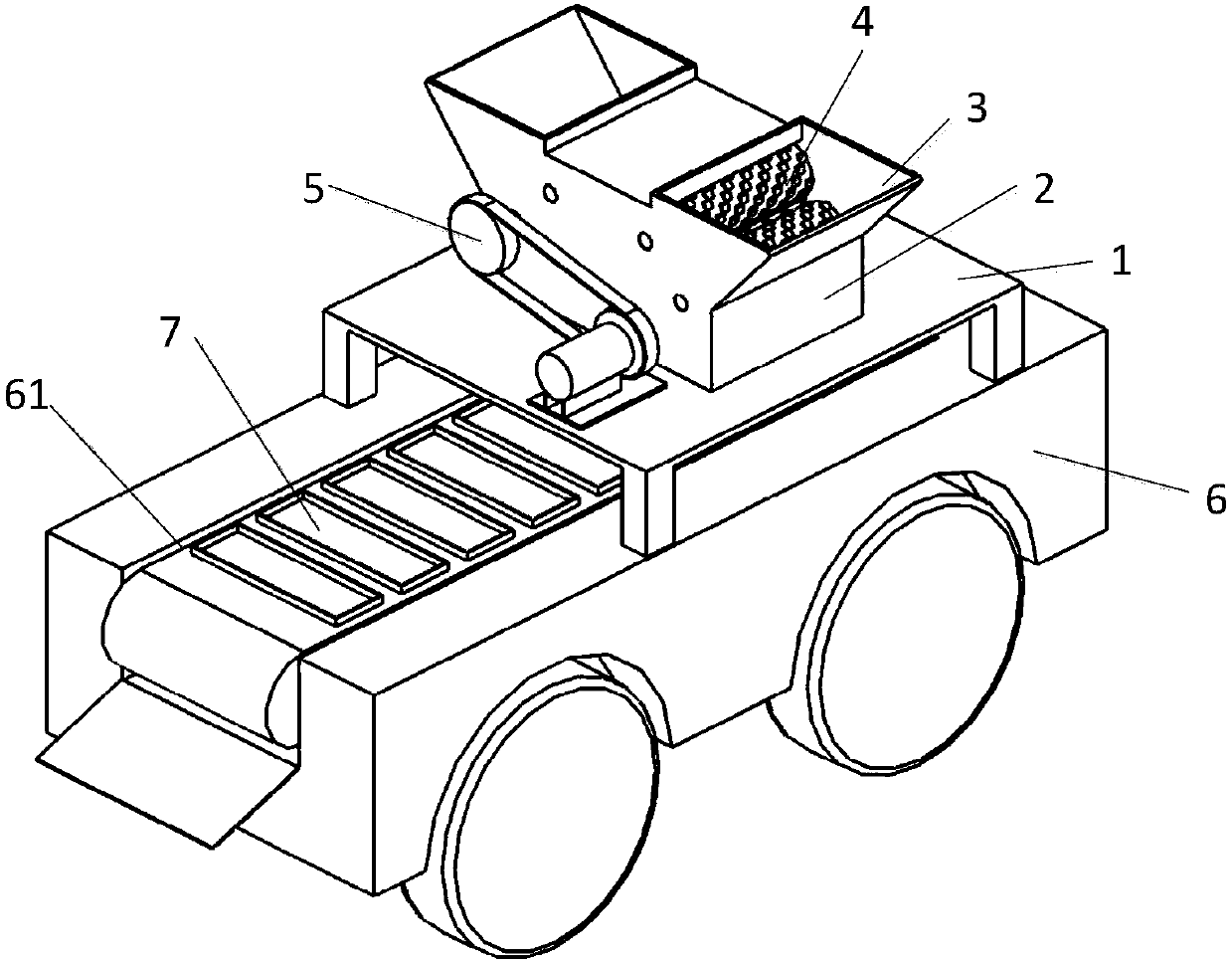

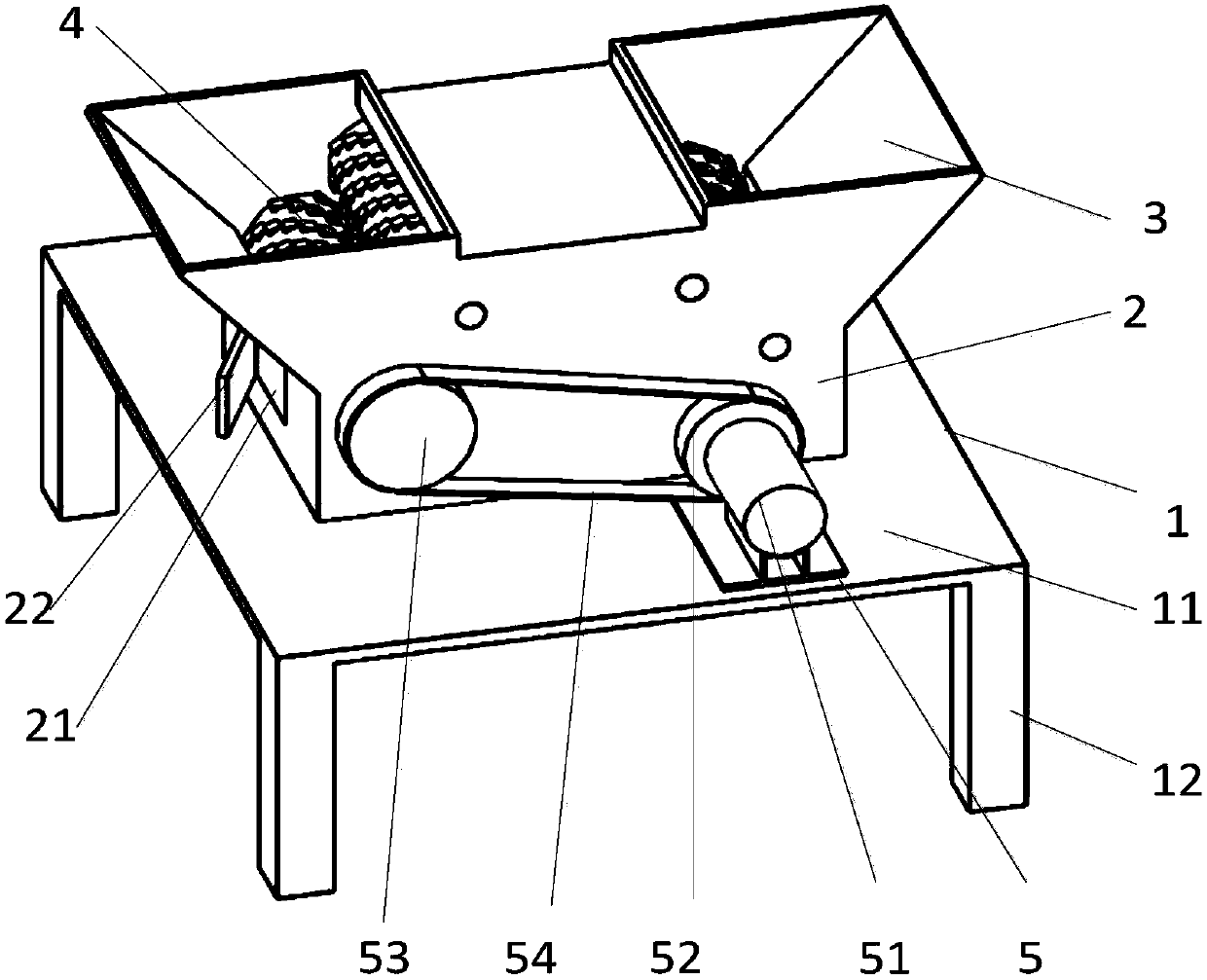

[0031] Such as figure 1 Shown, a wood crushing vehicle is characterized in that: it comprises a frame 1, a housing 2, a material inlet 3, a crushing roller 4, a driving device 5, a car body 6 and a conveyor belt device 7; the car body 6 is arranged on the frame 1 below, its upper end surface is fixedly connected with the lower end surface of frame 1; its upper end surface is provided with a downwardly recessed rectangular groove 61, the rectangular groove 61 is arranged along the length direction of the vehicle body 6 and is located directly below the discharge port, the rectangular groove 61 Close to the tail of the car body 6 is non-closed; the conveyor belt device 7 is arranged in the rectangular groove 7, and the wood chips discharged from the discharge port are conveyed from the front of the car body 6 to the rear of the car;

[0032] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com