Composite liner mask

A mask and liner technology, applied in the field of masks, can solve the problems of limited use of masks, small filter layer area, poor overall sealing, etc., and achieve the effects of simple structure, good sealing effect, and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

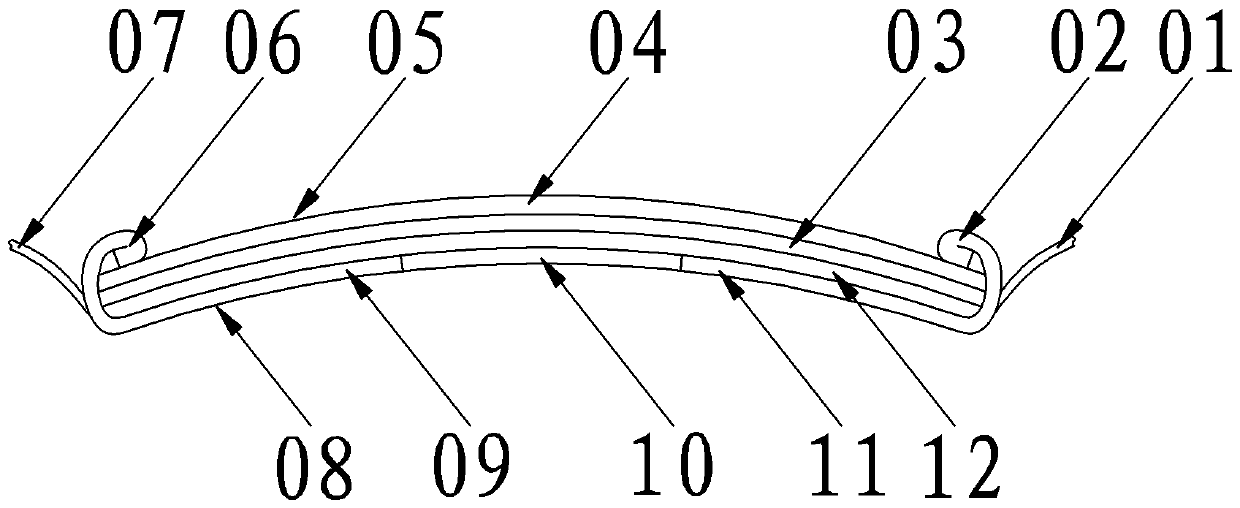

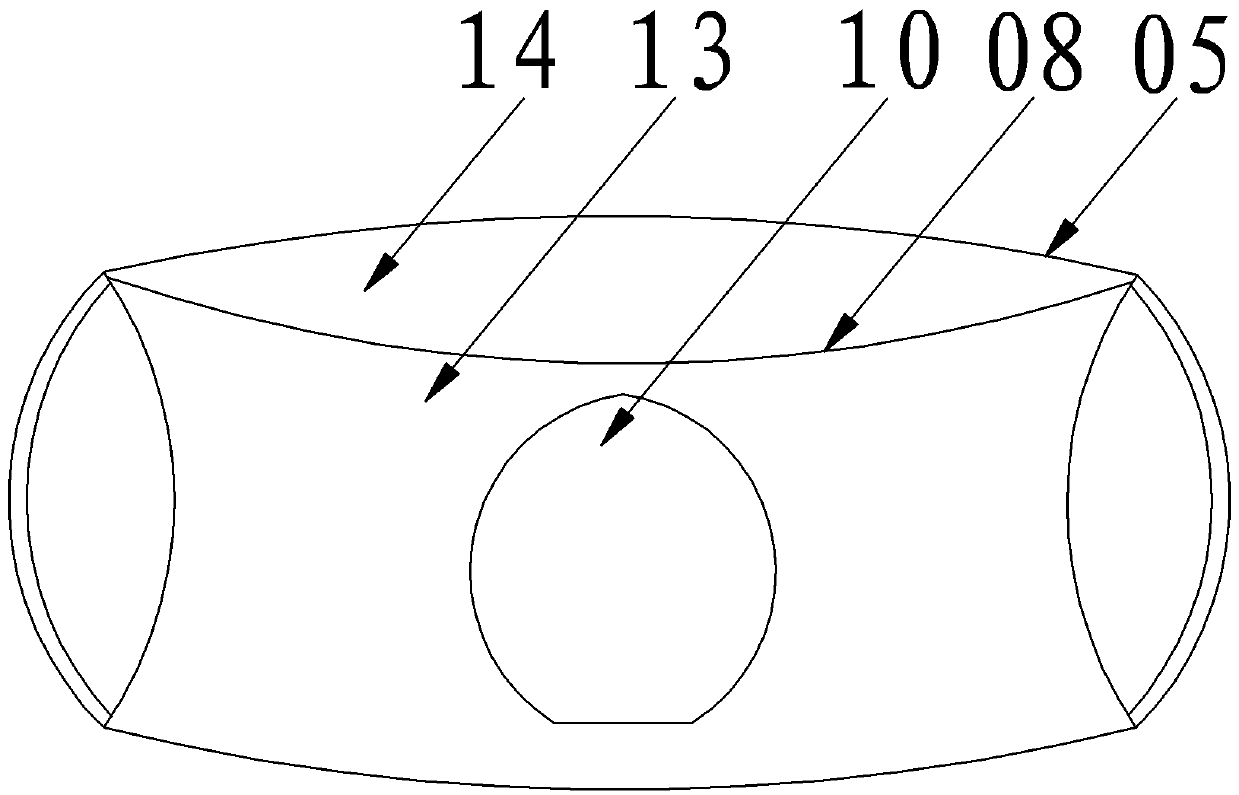

[0020] Example 1, such as figure 1 Shown, mouth mask body 05 is made up of mouth mask surface layer 04, mouth mask filter layer 03, mouth mask breathable layer 12, and mouth mask composite lining layer 08. Mask top layer 04 is for fixing mask body 05 effect. Mask filter layer 03 uses mask filter material, which functions to filter air impurities and harmful substances, and purify the air. Air-permeable layer 12, separating filter layer 03 and mouth mask composite inner lining layer 08, forms the gas circulation channel of support space, gathers the air passing through mask filter layer 03, can make full use of the use area of filter layer 03, and air-permeable layer 12 lays supportable For breathable materials, such as structural materials such as woven wire mesh with a thickness of more than 1MM, the material is selected from anti-condensation materials or the surface is treated with anti-condensation to prevent or reduce the condensation phenomenon of the material when it...

Embodiment 2

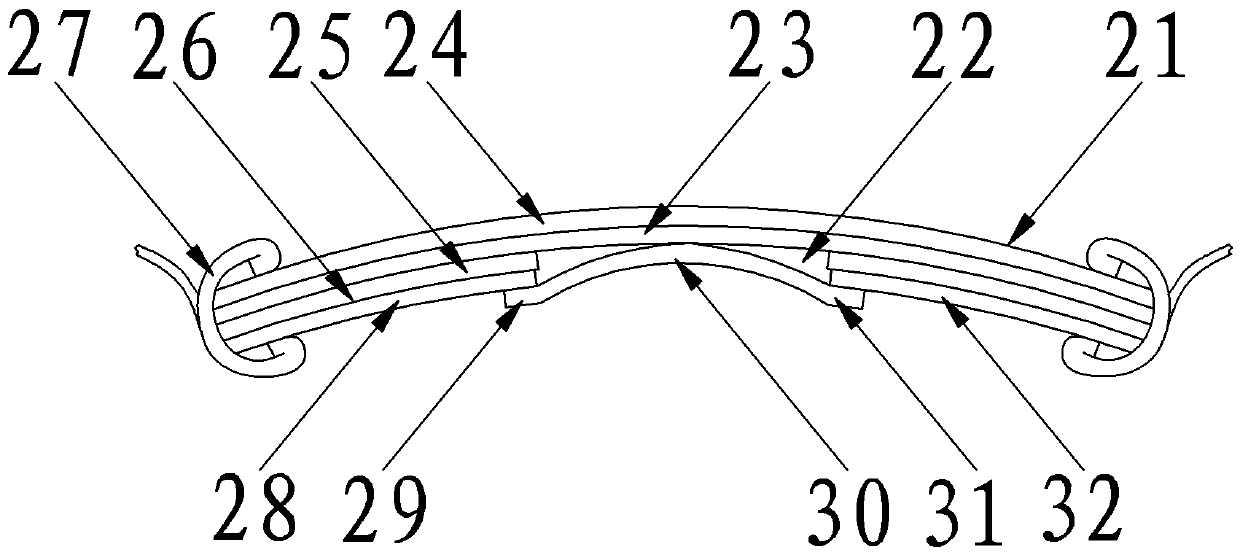

[0022] Example 2, such as image 3 Shown, mouth mask body 21 is made up of mouth mask surface layer 24, mouth mask filter layer 23, mouth mask breathable layer 25, mouth mask composite lining layer 26. The air-permeable layer 25 is provided with a hollow area 22, and the hollow area 22 is not provided with air-permeable materials, which does not affect the use of the mask. Composite inner liner 26 is made up of mouth and nose area lining 30, peripheral portion lining 28, peripheral portion lining 32; Air-permeable material; the connecting portion 29 connecting the nose and mouth area lining 30 and the peripheral lining 28, and the connecting portion 31 of the peripheral lining 32 are respectively overlapped and connected, and the breathable sheet 26 can be installed and disassembled through the connecting portion 29 or the connecting portion 31. The air-permeable layer 25 can be connected with each non-breathable lining of the mouth mask composite lining 26 as an integral str...

Embodiment 3

[0024] Example 3, such as Figure 5 As shown, both sides of the mouth and nose area lining sheet 44 of the composite liner breathable material have a peripheral non-breathable lining sheet 42 and a peripheral portion non-breathable lining sheet 42 respectively, and the mouth and nose area lining sheet 44 upper end of the composite lining layer breathable material Extend to upper mouth mask body wrapping place 43, the nose and mouth area liner 44 lower end of composite liner breathable material extends to mask body lower wrapping 41. The upper and lower ends of the mouth and nose area lining 44 of the composite liner breathable material in this embodiment extend to the edge of the mask body respectively, and can also be extended to the edge of the mask body with a single upper end or a single lower end during practical application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com