Beam and pile anchor foundation for towers

A base and tower technology, applied in the field of improved base, can solve problems such as being susceptible to weather conditions and other site conditions, thermal cracking of concrete, adverse effects, etc., to eliminate the risk of thermal cracking, reduce waste, reduce The effect of erection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

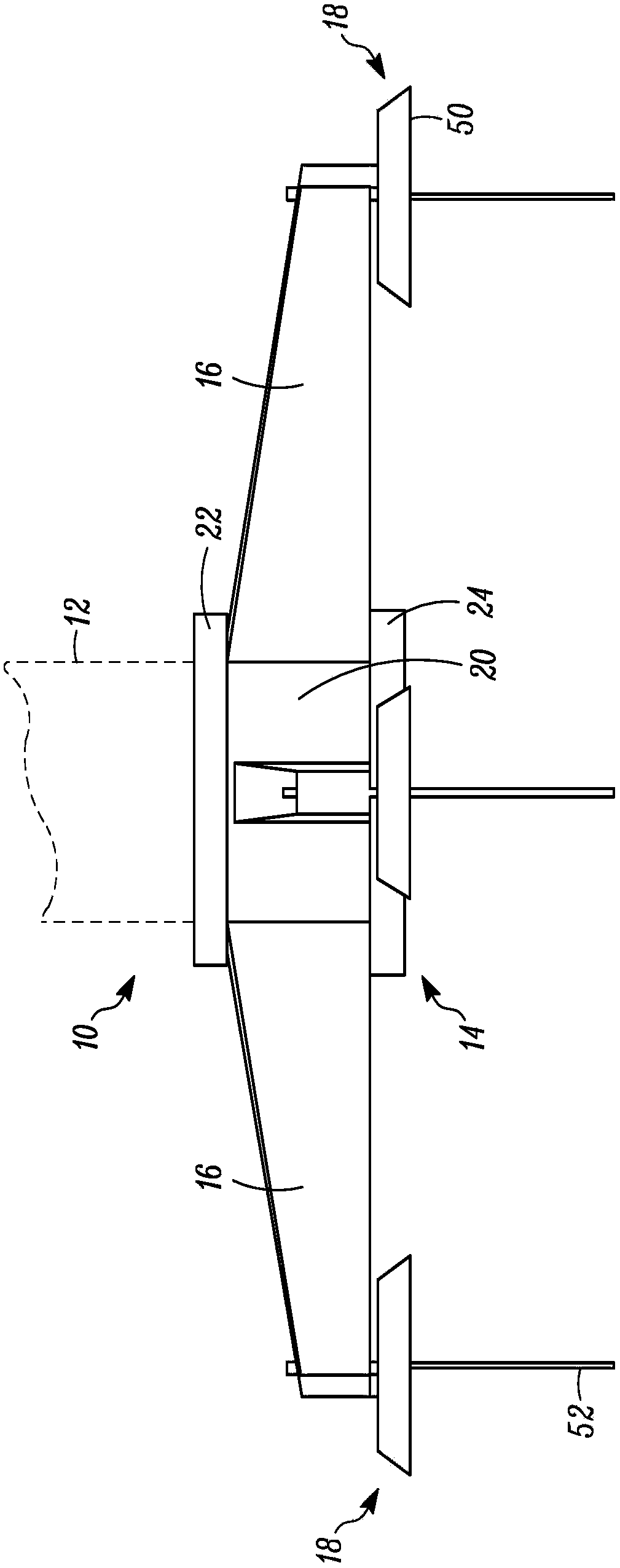

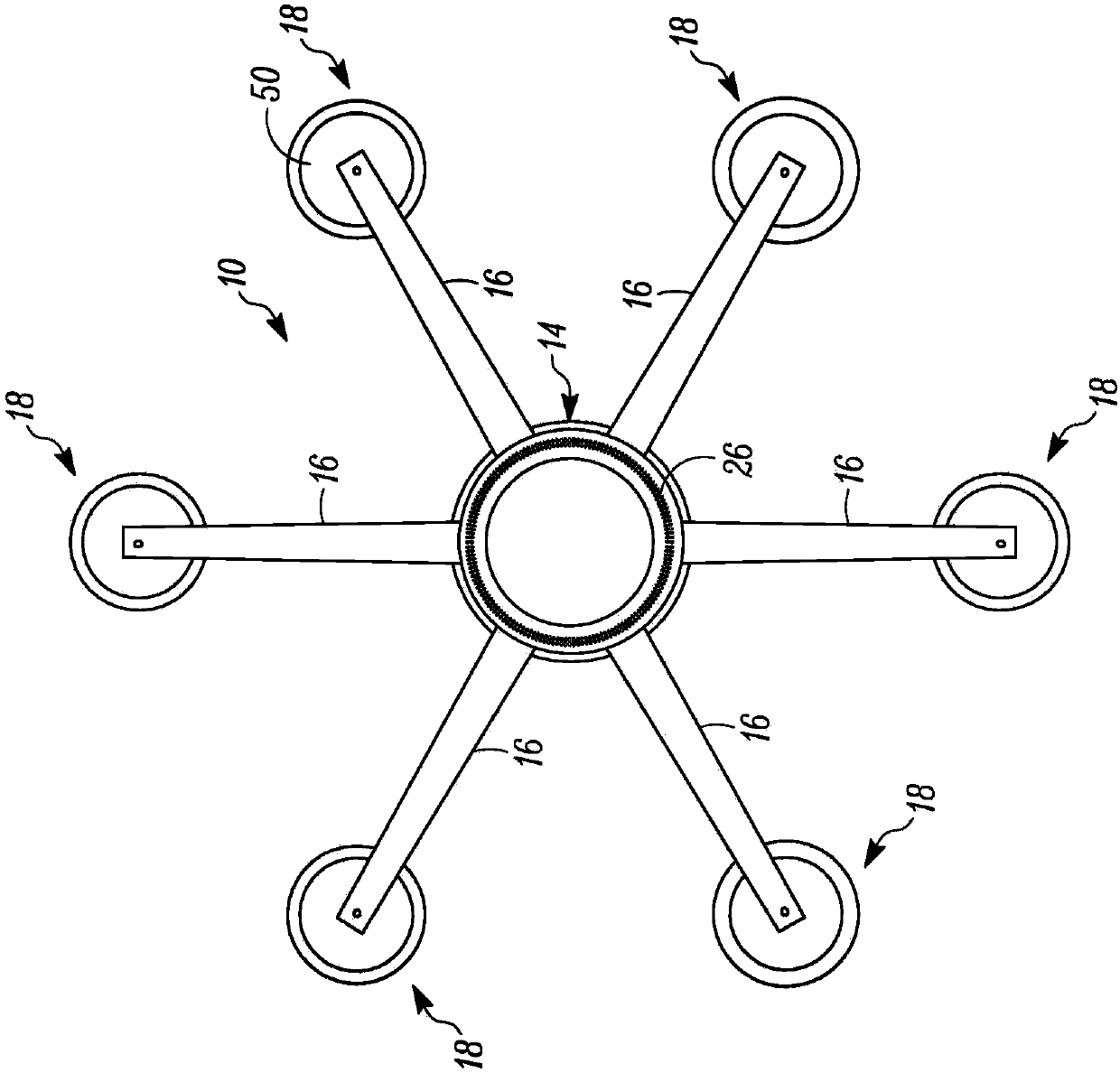

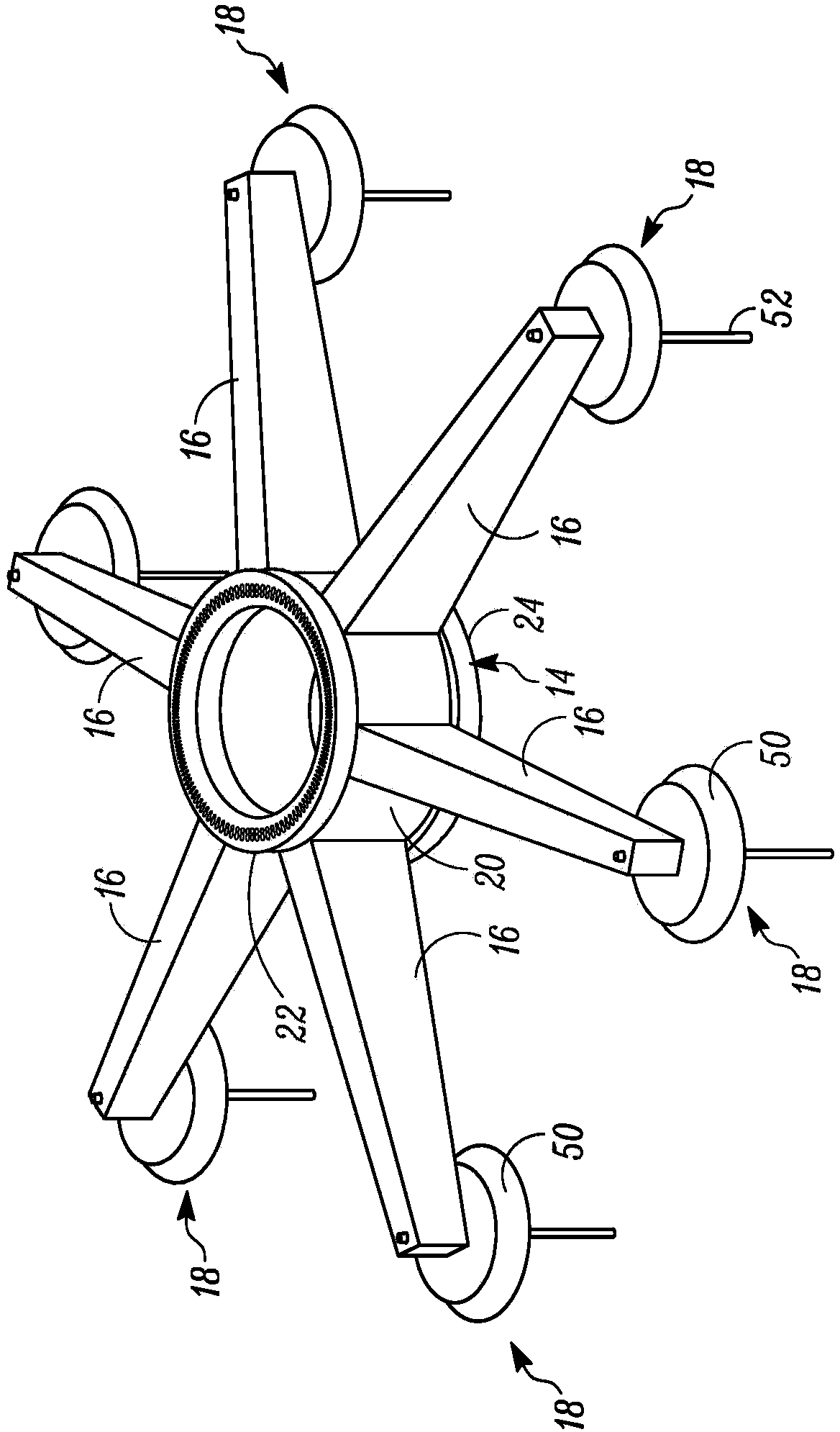

[0078] Embodiment 1: A foundation system for a wind turbine, the foundation system comprising:

[0079] center hub assembly;

[0080] a plurality of prestressed inverted spherical tee concrete beams arranged in offset pairs, wherein each pair includes at least one post-tensioning cable inserted from the distal end of the first beam to the proximal end of the offset beam, and the cables pass through the central hub assembly; and

[0081] At least one anchor configured below leveled ground and mechanically coupled to at least one inverted ball-end T-beam.

Embodiment approach 2

[0082] Embodiment 2: The foundation system of Embodiment 1, wherein each inverted spherical tee concrete beam includes a top flange forming an upper surface and a bottom flange forming a bottom surface, and the bottom flange is larger than The top flange is wide, wherein, in use, the foundation system is arranged such that the bottom surface of the ball-joint T-beam bears on soil.

Embodiment approach 3

[0083] Embodiment 3: The foundation system of Embodiment 1, wherein each inverted ball-end concrete T-beam includes a plurality of post-tensioning cables, and the post-tensioning cables extend through the top projection rim and the bottom flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com