Urethane resin particles

一种聚氨酯树脂、颗粒的技术,应用在聚脲/聚氨酯涂料、涂层、乳胶漆等方向,能够解决不足储存稳定性、难以获得涂膜储存稳定性物理性质等问题,达到优异储存稳定性、增强储存稳定性、增强耐溶剂性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

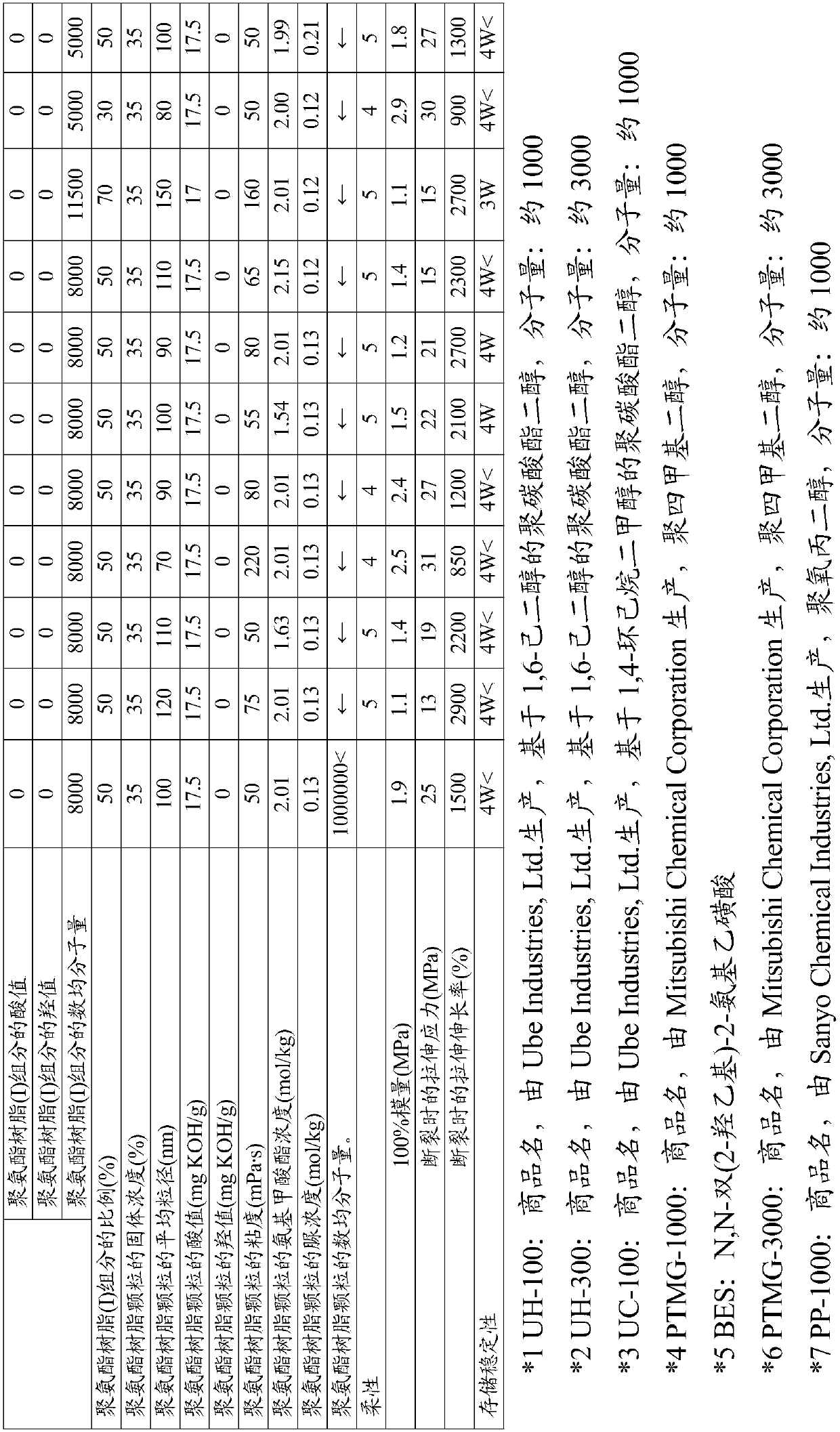

[0104] In terms of production stability and flexibility of the coating film obtained, the polyurethane prepolymer preferably has 0 to 100 mgKOH / g, particularly preferably 0 to 50 mg KOH / g, more particularly preferably 0 to 30 mg KOH / g and even more particularly preferably 0 to an acid value of 10mgKOH / g.

[0105] In terms of manufacturability, the polyurethane prepolymer preferably has a number-average molecular weight of 2,000 to 50,000, particularly preferably 2,000 to 30,000 and very particularly preferably 5,000 to 20,000.

[0106] Synthesis of Polyurethane Resin Particles

[0107] The present invention can be obtained by adding deionized water optionally with a neutralizing agent for ion-forming groups to a polyurethane prepolymer for water dispersion (emulsification), and if necessary, further performing a chain extension reaction and removing the solvent. An aqueous dispersion of inventive core-shell polyurethane resin particles.

[0108] The neutralizing agent is n...

Embodiment 1A

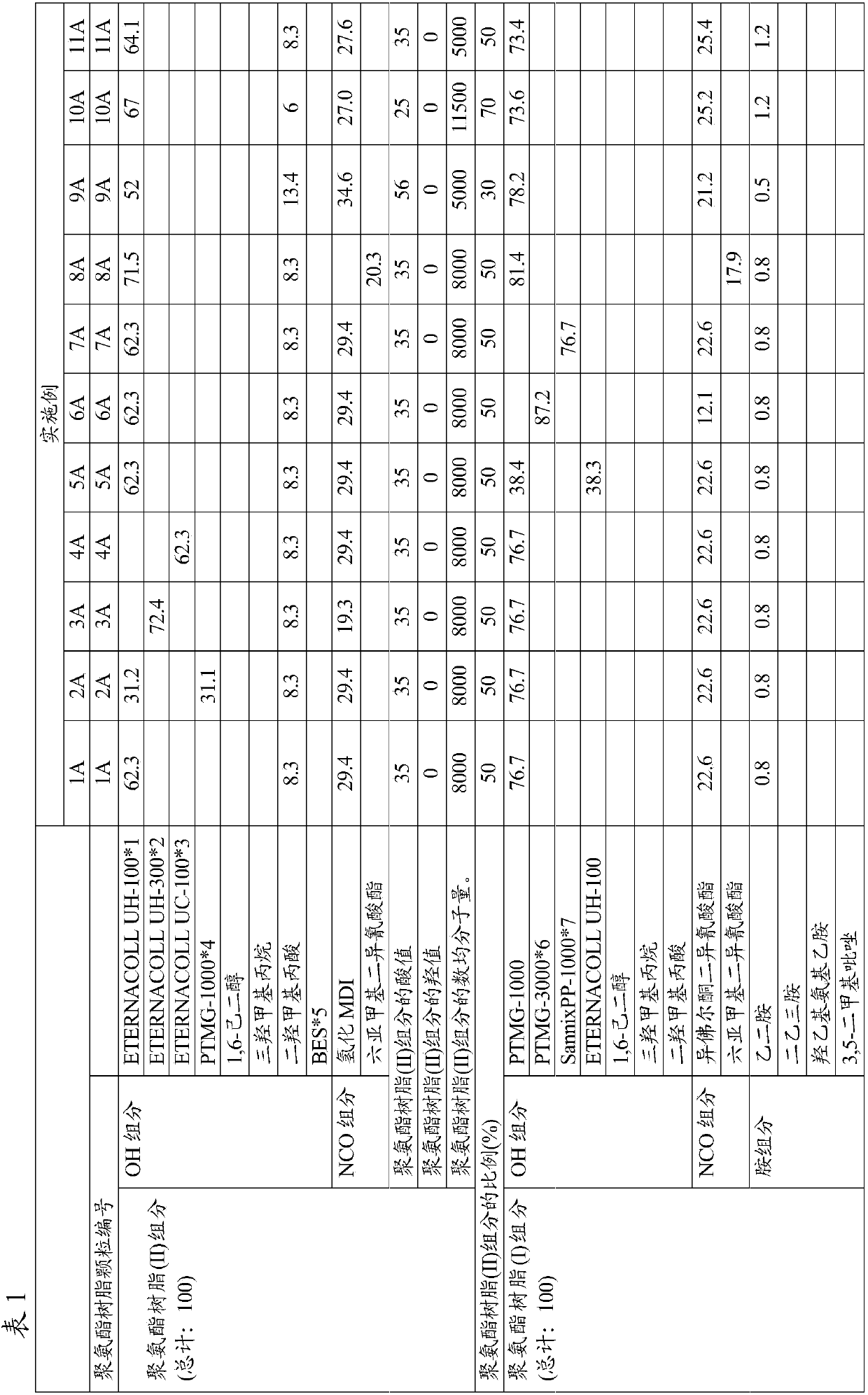

[0239] 62.3 parts of ETERNACOLL UH-100 (trade name, produced by Ube Industries, Ltd., 1,6-hexanediol-based polycarbonate diol, molecular weight: about 1,000) and 8.3 parts of dimethylolpropionic acid (the For the production of polyurethane resin (II) starting material), 0.1 part of NEOSTANN U-600 (trade name, produced by Nitto Kasei Co., Ltd., bismuth catalyst) and 200 parts of methyl ethyl ketone solvent were placed in a thermometer equipped with a thermometer , thermostat, stirrer and reflux condenser in the reaction vessel. After raising the temperature to 80°C with stirring, 29.4 parts of hydrogenated MDI (4,4'-dicyclohexylmethane diisocyanate) were added dropwise over a period of 30 minutes.

[0240] Then, while maintaining the temperature at 80° C., the reaction was performed until an NCO value of 1 mg / g or less was achieved.

[0241] The obtained polyurethane resin (II) had a number average molecular weight of 8000.

[0242] 76.7 parts of "PTMG-1000" (trade name, prod...

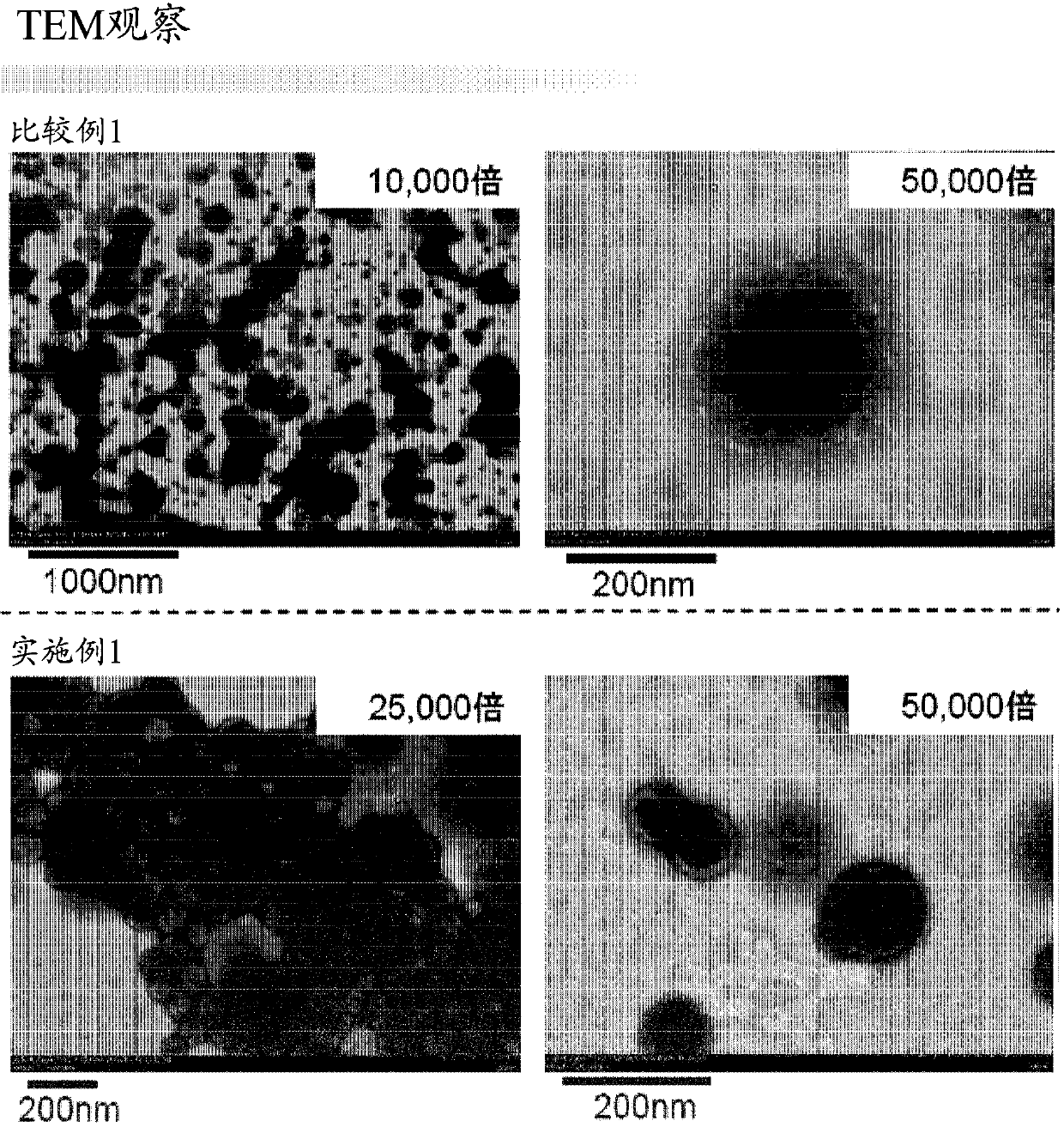

Embodiment 2A to Embodiment 18A and comparative example 1A to comparative example 3A

[0249] Aqueous dispersions of polyurethane resin particles No. 2A to No. 21A were obtained in the same manner as in Example 1A, but changing the composition as shown in Table 1 and Table 2 below. Tables 1 and 2 below include property values of the obtained aqueous dispersions of polyurethane resin particles.

[0250] The following Tables 1 and 2 show the composition ratios of each of the polyurethane resin (II) and the polyurethane resin (I) based on the total amount of the components of the respective resins (regarded as 100).

[0251] In the production method, the NCO value at the end of the reaction and the amount of methyl ethyl ketone solvent are appropriately adjusted according to the formula.

[0252] Aqueous dispersions of polyurethane resin particles No. 19A to No. 21A were used in Comparative Examples.

[0253] assessment test

[0254] The polyurethane resin particles 1A to 21A obtained in Example 1A to Example 18A and Comparative Example 1A to Comparative Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance coefficient | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com