Cantilever crane

A cantilever crane and cantilever technology, applied in the field of cantilever cranes, can solve the problems of long cantilever, bulky, unable to achieve self-locking, etc., and achieve the effect of locking safety and preventing collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

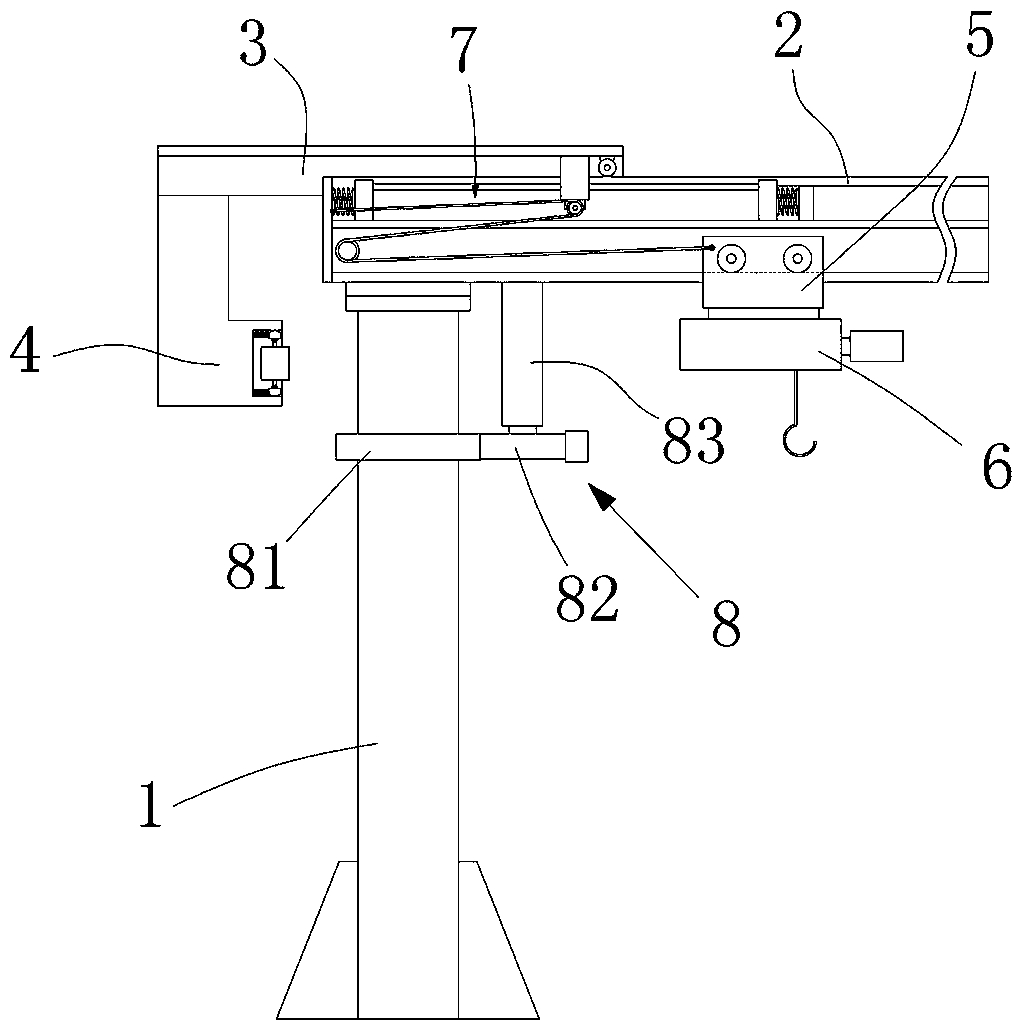

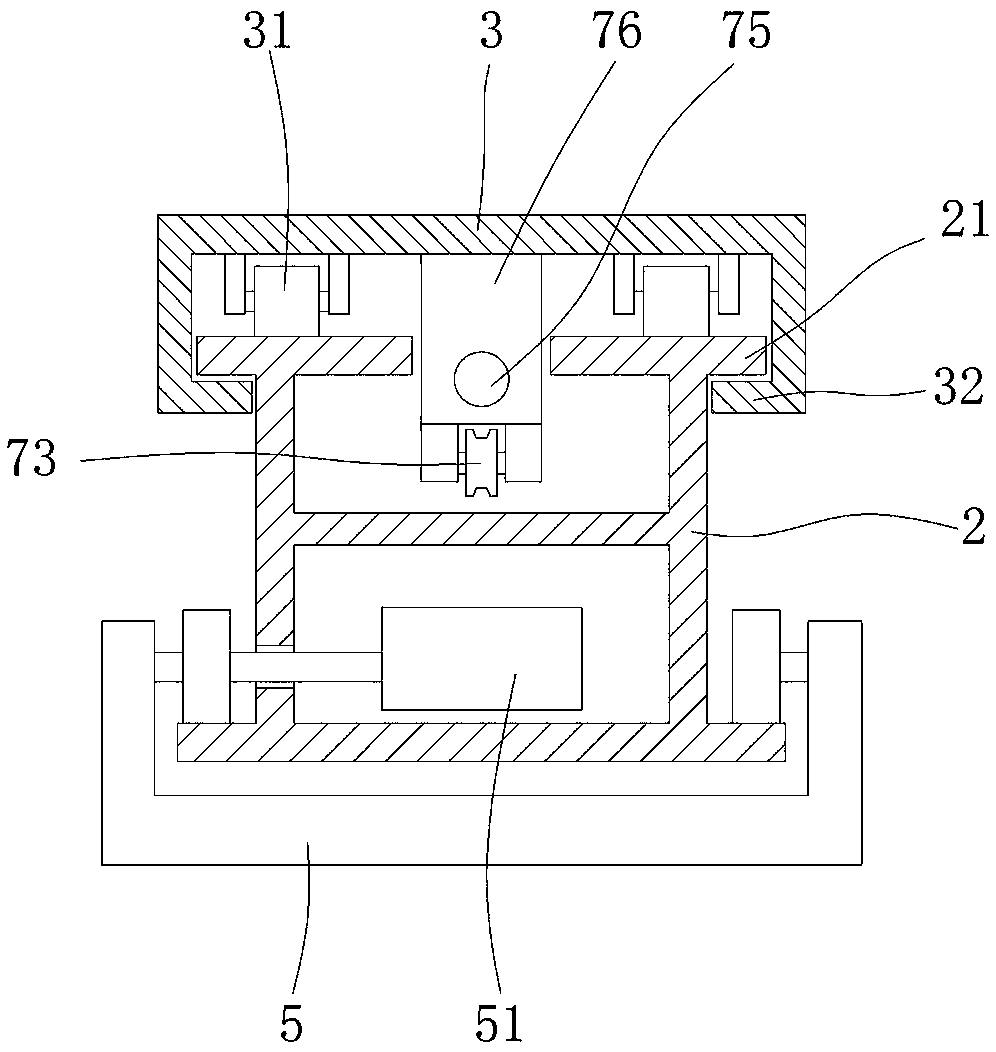

[0022] Example: such as Figure 1-5 As shown, a cantilever crane includes a column 1, a boom, a mobile trolley 5 moving along the boom and an electric hoist 6 mounted on the mobile trolley 5, and the boom is mounted on the column 1 through a rotating support. And rotate relative to the column 1. The rotation support includes an upper support plate arranged at the end of the boom and a lower support plate arranged on the column 1, and the upper and lower support plates are connected by a rotating shaft and a bearing.

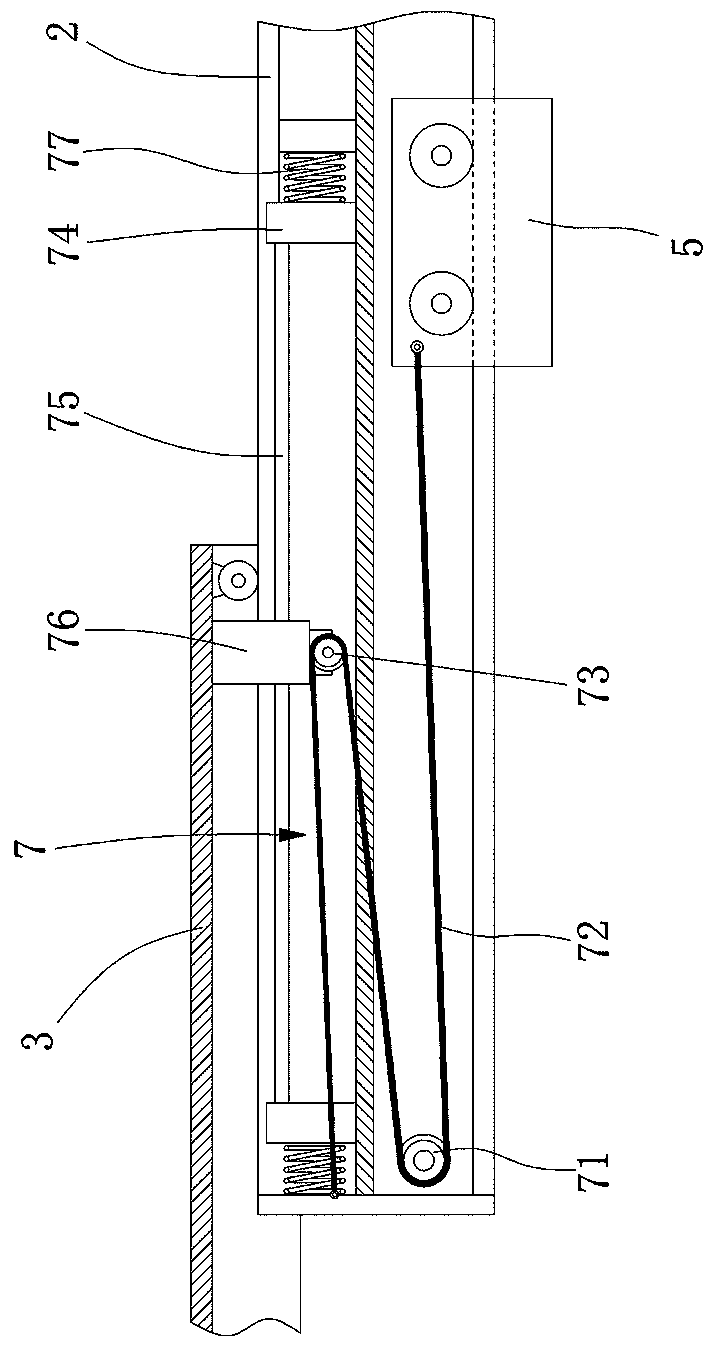

[0023] Such as figure 1 , figure 2 and image 3 As shown, the boom is a telescopic structure, including a boom 2 and a balance arm 3. One end of the boom 2 is rotatably mounted on the column 1, and the balance arm 3 is slidably mounted on the boom 2 and moves along the boom 2. The length direction of moving, the driving mechanism 7 that drives the balance arm 3 to move is arranged between the moving trolley 5 and the balance arm 3, so that the balance arm 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com