Cooling device with lateral heating function in furnace

A cooling device and cooling belt technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, long cooling time, leakage, etc., to improve work efficiency, prevent heat leakage, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

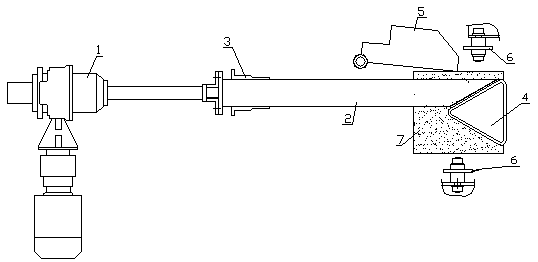

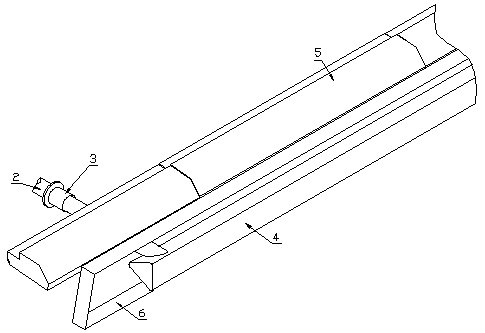

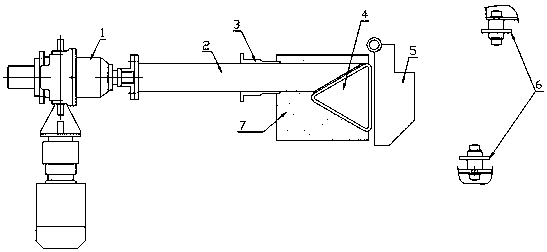

[0024] With reference to accompanying drawing: the technical scheme that the present invention solves its technical problem adopts is: a kind of cooling device with side heating in the furnace, comprises heating band 6 and cooling band 4, and heating band 6 and cooling band 4 are arranged in the brazing furnace Inside, the cooling belt 4 is driven by the linear drive 1 to move to cool the workpieces in the brazing furnace. The device can quickly switch the cooling device between two working states of heating and cooling.

[0025] The linear drive 1 is connected to the cooling belt 4 via a circular connection 2 .

[0026] The circular connection 2 passes through the sealing ring 3 of the shell of the brazing furnace to be connected with the transmission device, and the sealing ring 3 of the shell is provided to prevent the heat in the furnace from leaking out.

[0027] The front end of cooling band 4 is provided with movable heat preservation door 5 that can rotate, and movabl...

Embodiment 2

[0032] Compared with Embodiment 1, there are the following differences in the cooling device with side heating in the furnace of the present embodiment:

[0033] With reference to accompanying drawing: cooling band 4 drives it to move by cylinder, and the workpiece in the brazing furnace is cooled.

[0034] The cross-section of the cooling zone 4 is a semicircular wavy structure.

[0035] Working principle and using method of the present invention:

[0036] In the cooling device, the linear drive 1 can drive the cooling belt 4 to stretch back and forth. When the brazing furnace starts working and heating, the linear drive 1 drives the cooling belt 4 to shrink, and the movable heat preservation door 5 turns to the vertical closed position due to gravity, and the heating belt 6 starts heating at the same time; During cooling, the linear drive 1 drives the cooling belt 4 to stretch out, and the cooling belt 4 pushes the movable heat preservation door 5 to the horizontal opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com