A vacuum emulsification tank

A vacuum emulsification and tank technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve problems such as the inability to observe the state of the emulsification tank medium, and achieve the effect of simple structure and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: A kind of vacuum emulsification tank

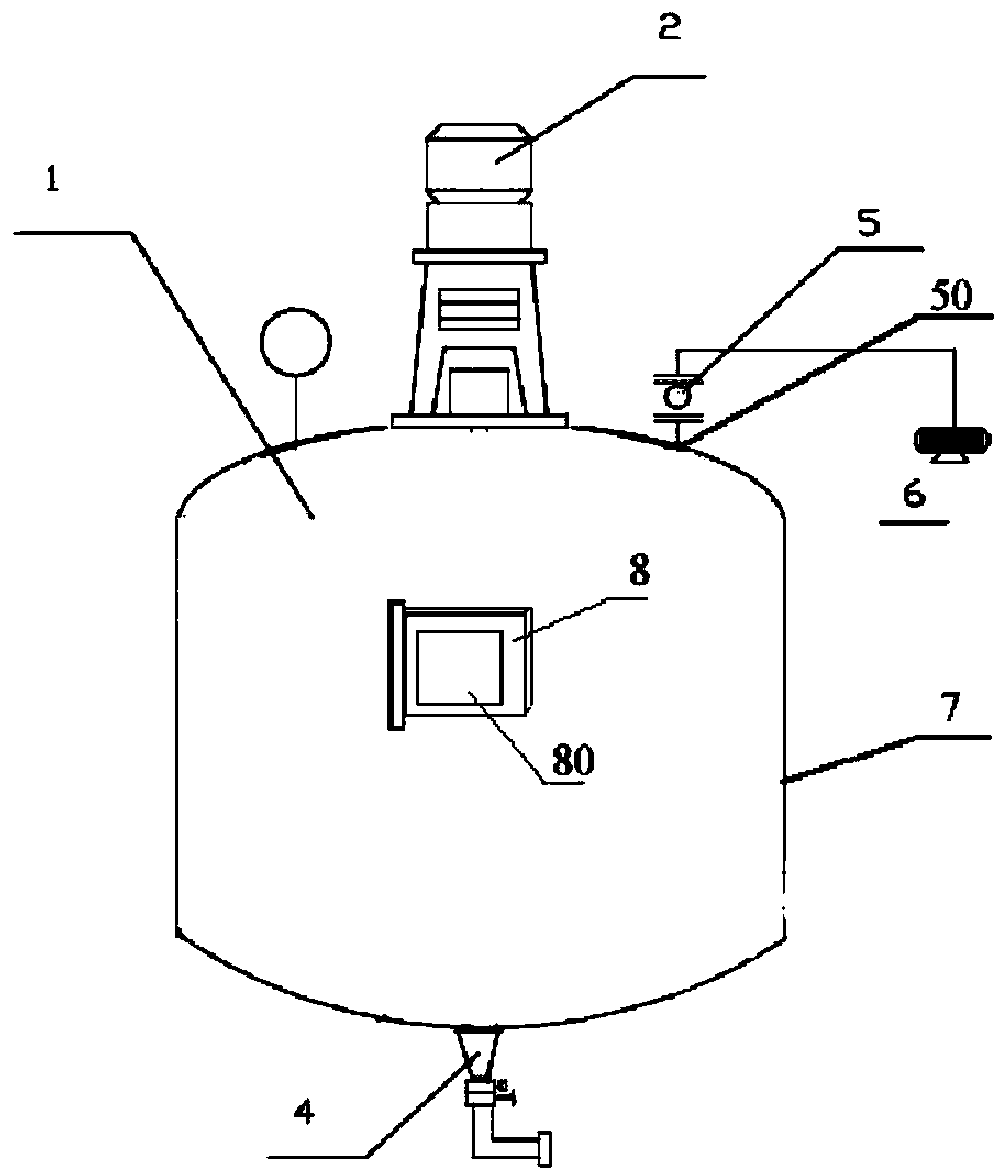

[0020] Such as Figure 1 to Figure 3 As shown, an emulsification tank device includes a cylindrical tank body 1 provided with a feed port and a discharge port 4 located at the bottom of the tank body 1 .

[0021] The top of the tank body 1 is provided with a rotating motor 2 and a vacuum pump 5, the output shaft of the rotating motor 2 is connected to the stirring shaft 30 of a stirrer, and the stirring paddle 3 of the stirrer is located inside the tank body 1 for The medium inside the tank body 1 is stirred. Stirring can make the material mix more evenly and react more fully. At the same time, during the reaction process, air bubbles will be generated, and the stirring of the material is also conducive to the elimination of air bubbles.

[0022] The vacuum pump 5 includes an exhaust port 50 and a suction port 51, and the suction port 51 communicates with the inside of the tank 1 through a vacuum tube.

[0023] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com