Irrigating device after corn planting

A technology of watering device and corn, applied in the field of watering device and watering device after corn is sown, can solve the problems such as insufficient uniform and comprehensive land watering, working width of adjusting device, poor watering efficiency, etc., to ensure universality , Change the watering position, use the effect of saving time and effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

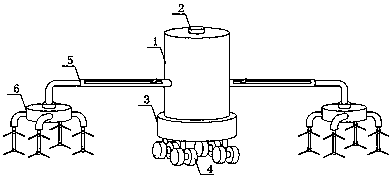

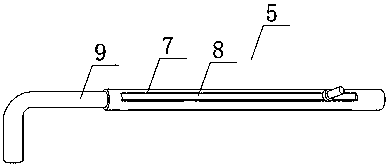

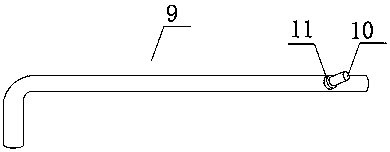

[0028] See Figure 1-7 As shown, a watering device used for corn after sowing includes a water tank 1, an electric roller 4, a water delivery tray 5, a watering rack 6 and a pouring tray 19, four electric rollers 4 are arranged under the water tank 1, and the water tank 1 A power distribution box 3 is arranged between the electric roller 4 and both ends of the water tank 1 are provided with a water supply tray 5, and a watering rack 6 is provided under the water supply tray 5, and the side walls of both ends of the water tank 1 are provided with a water supply tray 5 Matching water receiving port 13; a mounting ring 7 is horizontally arranged on the water supply tray 5, and a chute 8 is horizontally arranged on the mounting ring 7, and a water pipe 9 is clamped inside the mounting ring 7; the upper middle part of the watering rack 6 is provided for convenience and communication The connecting block 15 to which the water pipe 9 is connected, and the connecting block 15 is provide...

Embodiment 2

[0030] In addition, please continue to see Figure 2-7 As shown, the difference from the above-mentioned embodiment is that a water-filling cover 2 is screwed on the upper middle of the water tank 1, and the water tank 1 is filled with water through the water-filling cover, and the outer ring of the water tank 1 is laid with a sealing plate 14 to prevent water leakage. The water pipe 9 is vertically provided with a sliding clip post 10, and the sliding clip post 10 is screwed with a tightening bolt 11, and the extension of the water pipe 9 is changed by sliding the sliding clip post 10 back and forth on the chute 8 of the ring 7 Length, thereby changing the working position of the two watering racks 6, so that the overall watering position and overall width of the device are changed, so that the device is more accurate in the watering position of the ground. The sliding clamp post 10 penetrates the chute 8 and is sliding The diameter of the clamping post 10 matches the width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com