Corn thresher with auto-threshing function

A technology for thresher and corn, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as unfavorable overall efficiency, improvement, labor intensity, etc., to ensure purity, avoid incompleteness, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0019] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

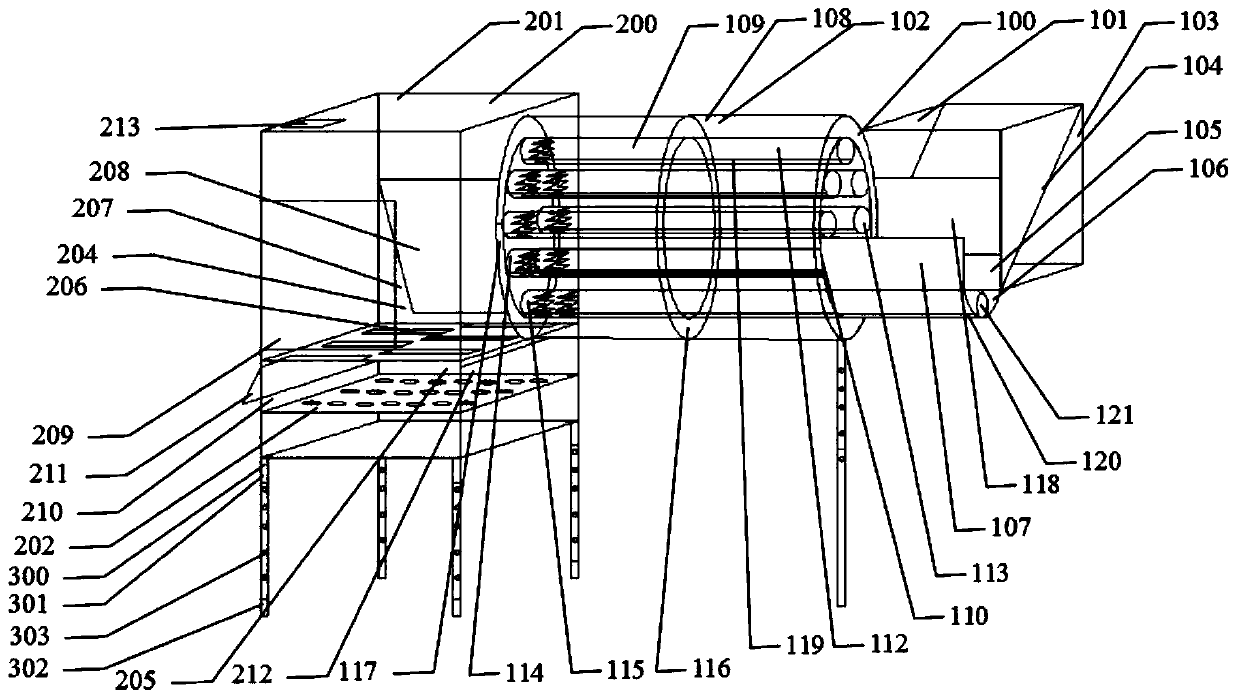

[0020] Such as figure 1 As shown, the invention provides a corn thresher that can automatically thresh, comprising:

[0021] Feeding device 100, it comprises shelving basket 101 and feed cylinder 102, and said shelving basket 101 is arranged on the side of the inlet of said feed cylinder 102, and said shelving basket 101 comprises square frame body 103 and first compartment plate 104, the first partition 104 is arranged in the square frame body 103, and forms an included angle of 30-45 degrees with the bottom plate of the square frame body 103, and the bottom of the square frame b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com