Composite conductive agent and preparation method thereof, electrode plate and lithium ion battery

A technology of composite conductive agent and composite material, which is applied in the field of lithium ion battery, composite conductive agent and its preparation method, and pole piece, and can solve the problems of small improvement, unimproved tap density of composite conductive agent, and influence on the energy of lithium ion battery. Density improvement and other issues, to achieve the effect of high efficiency, overall conductivity and mechanical properties, and large specific capacity for the first time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

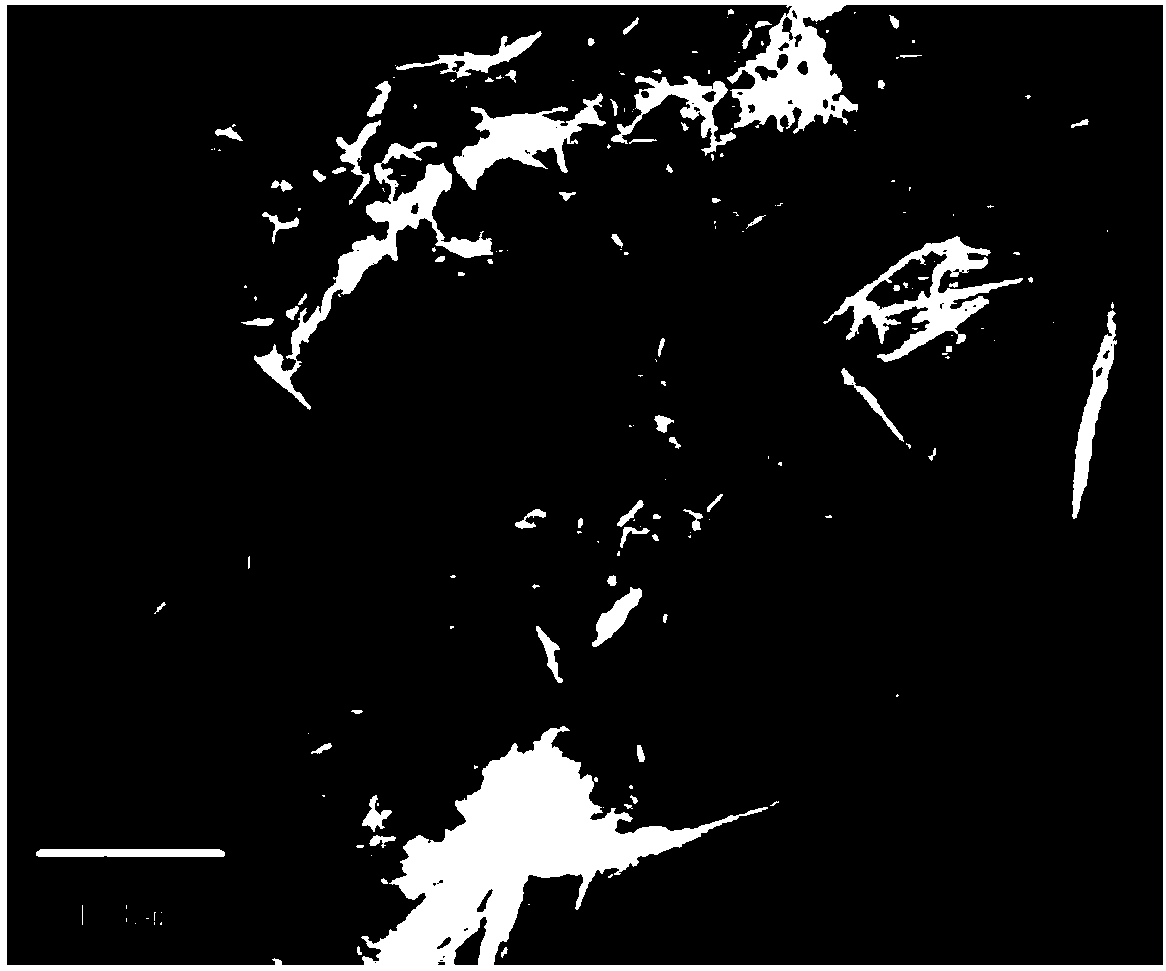

Image

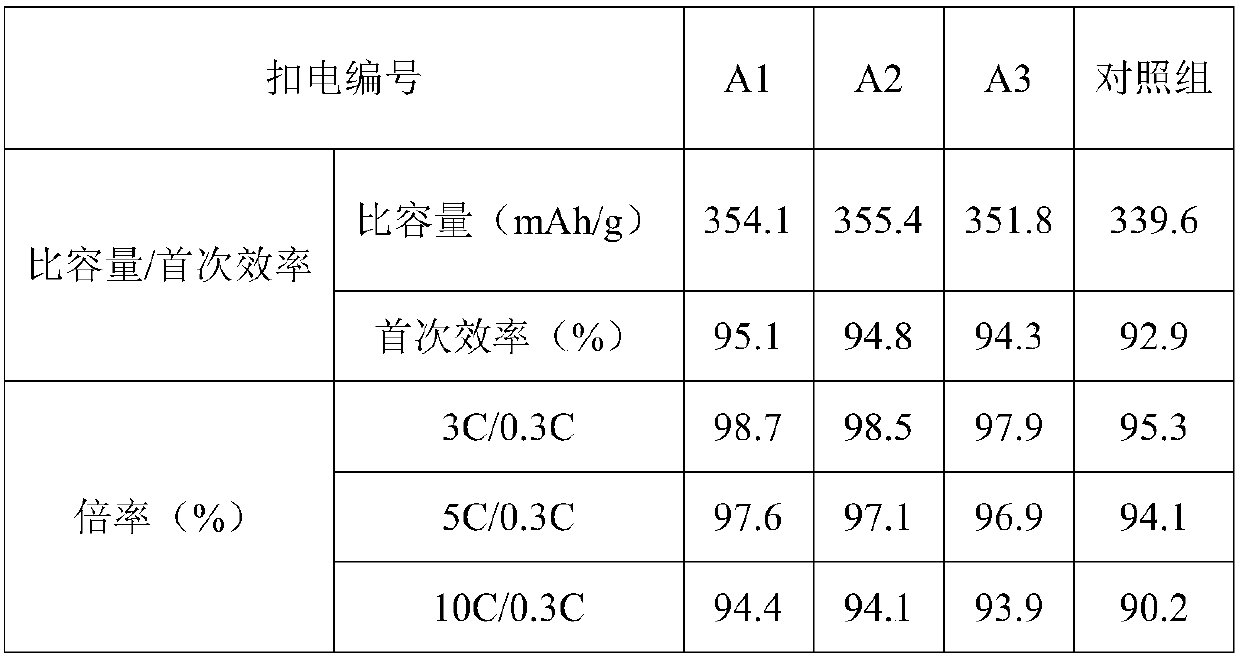

Examples

Embodiment 1

[0048] The preparation method of the composite conductive agent of the present embodiment comprises the following steps:

[0049] 1) Catalyst load:

[0050]The carbon black with a particle size of 200nm was washed with deionized water, dried, and then washed 50 times with 0.1mol / L hydrochloric acid solution, and then washed 50 times with 0.1mol / L sodium hydroxide solution. After drying, the pretreated Carbon black of 100nm nickel catalyst and 96g citric acid were added to 1000mL of deionized water to prepare mixed solution A, and then 100g of pretreated carbon black was added to 2000mL mixed solution A. And soak for 24 hours at 80°C and 5MPa under high pressure to obtain material B;

[0051] 2) Preparation of carbon black / carbon nanotubes:

[0052] Put material B into a quartz boat and put it in the middle of the tube furnace, raise the temperature to 800°C under the protection of inert gas, keep it warm for 2 hours, then change it to hydrogen for 180 minutes, then keep it a...

Embodiment 2

[0058] The preparation method of the composite conductive agent of the present embodiment comprises the following steps:

[0059] 1) Catalyst load:

[0060] Wash the carbon black with a particle size of 100nm with deionized water and dry it with 0.1mol / L hydrochloric acid solution for 50 times, then wash it with 0.1mol / L sodium hydroxide solution for 50 times, and dry it to obtain the pretreated carbon black; after that, 5.9g of ferric nitrate catalyst with a particle size of 10nm and 19.2g of citric acid were added to 200mL of deionized water to prepare mixed solution A, and then 100g of pretreated carbon black was added to 200mL of mixed solution A , and soaked at 25°C and 10MPa high pressure for 48h to obtain material B;

[0061] 2) Preparation of carbon black / carbon nanotubes:

[0062] Put material B into a quartz boat and put it in the middle of the tube furnace, raise the temperature to 600°C under the protection of inert gas, keep it warm for 2 hours, then change it t...

Embodiment 3

[0068] The preparation method of the composite conductive agent of the present embodiment comprises the following steps:

[0069] 1) Catalyst load:

[0070] Carbon black with a particle size of 200nm was washed with deionized water, dried, and then washed 100 times with 0.1mol / L hydrochloric acid solution, then washed 100 times with 0.1mol / L sodium hydroxide solution, and dried to obtain the pretreated The carbon black of 200nm cobalt catalyst and 192g citric acid were added to 2000mL of deionized water to prepare mixed solution A, and then 100g of pretreated carbon black was added to 200mL mixed solution A. And soak for 48 hours at 200°C and 1MPa high pressure to obtain material B;

[0071] 2) Preparation of carbon black / carbon nanotubes:

[0072] Put material B into a quartz boat and place it in the middle of the tube furnace, raise the temperature to 800°C under the protection of inert gas, keep it warm for 2 hours, then change it to hydrogen for 350 minutes, then keep it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com