Height-adjustable high-strength rebar bracket

A technology of high-strength steel bars and steel bar brackets, applied in building reinforcements, structural elements, building components, etc., can solve problems such as easy mold escape, fragility, and hidden quality problems, and achieve the effect of ensuring reliability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

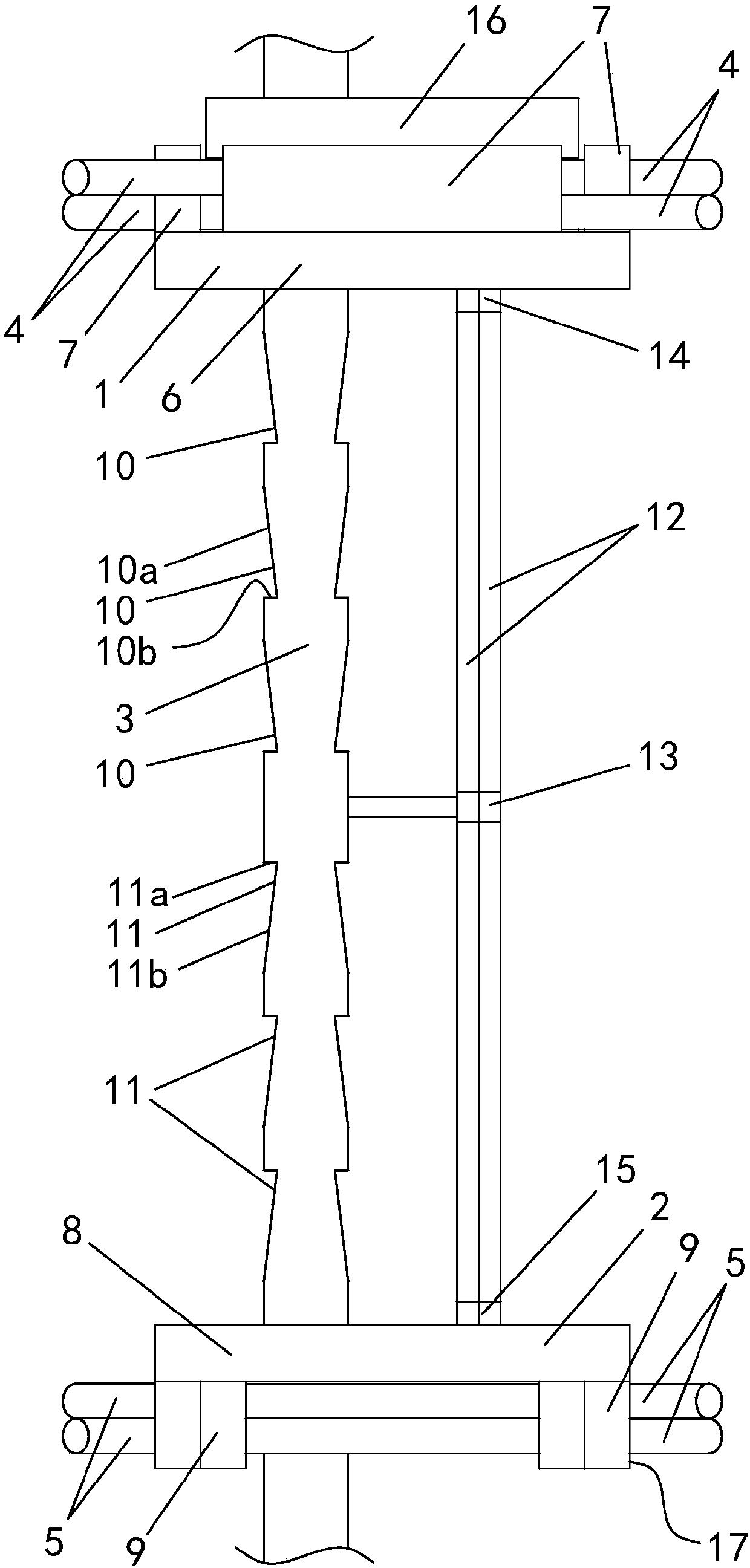

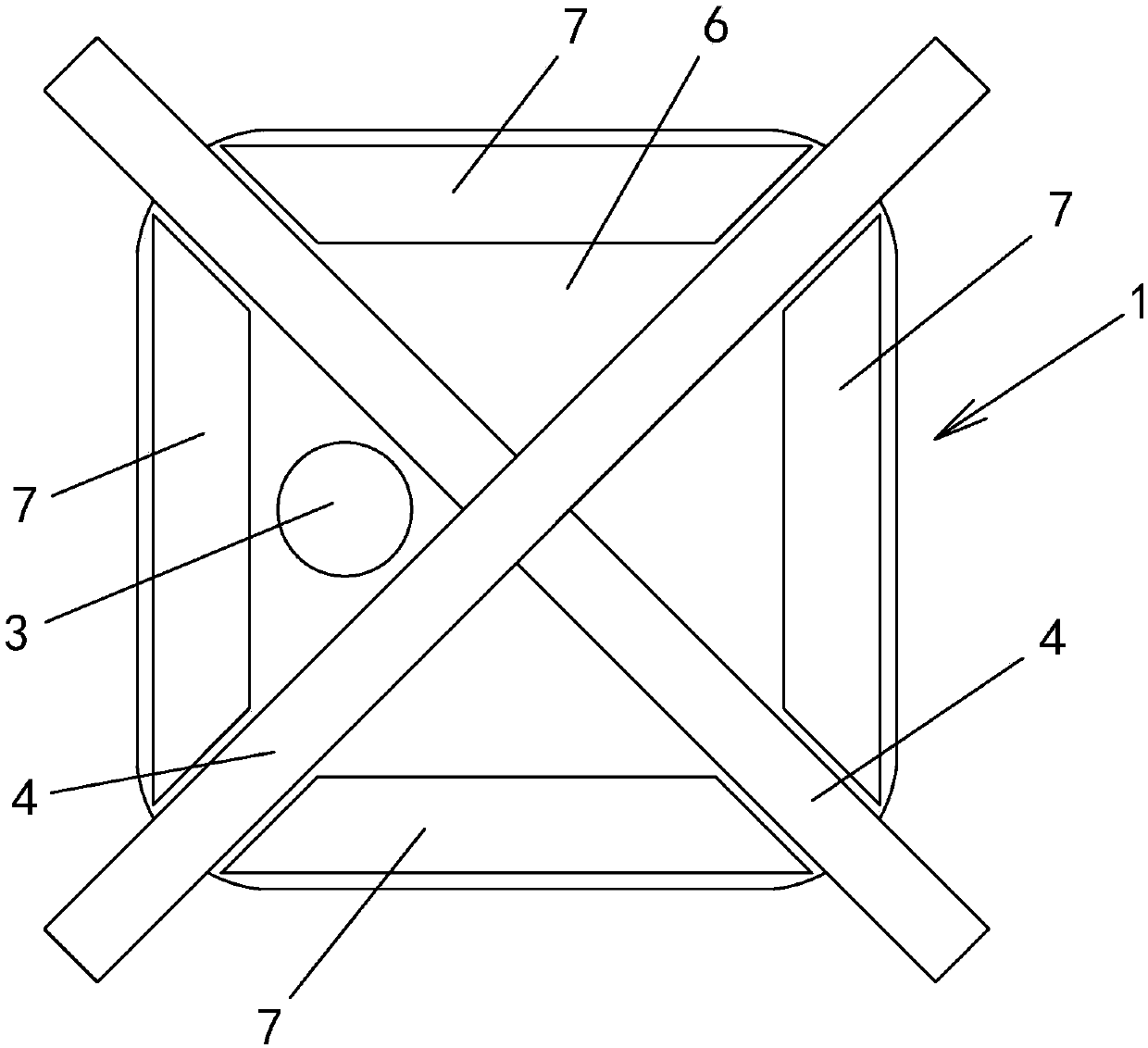

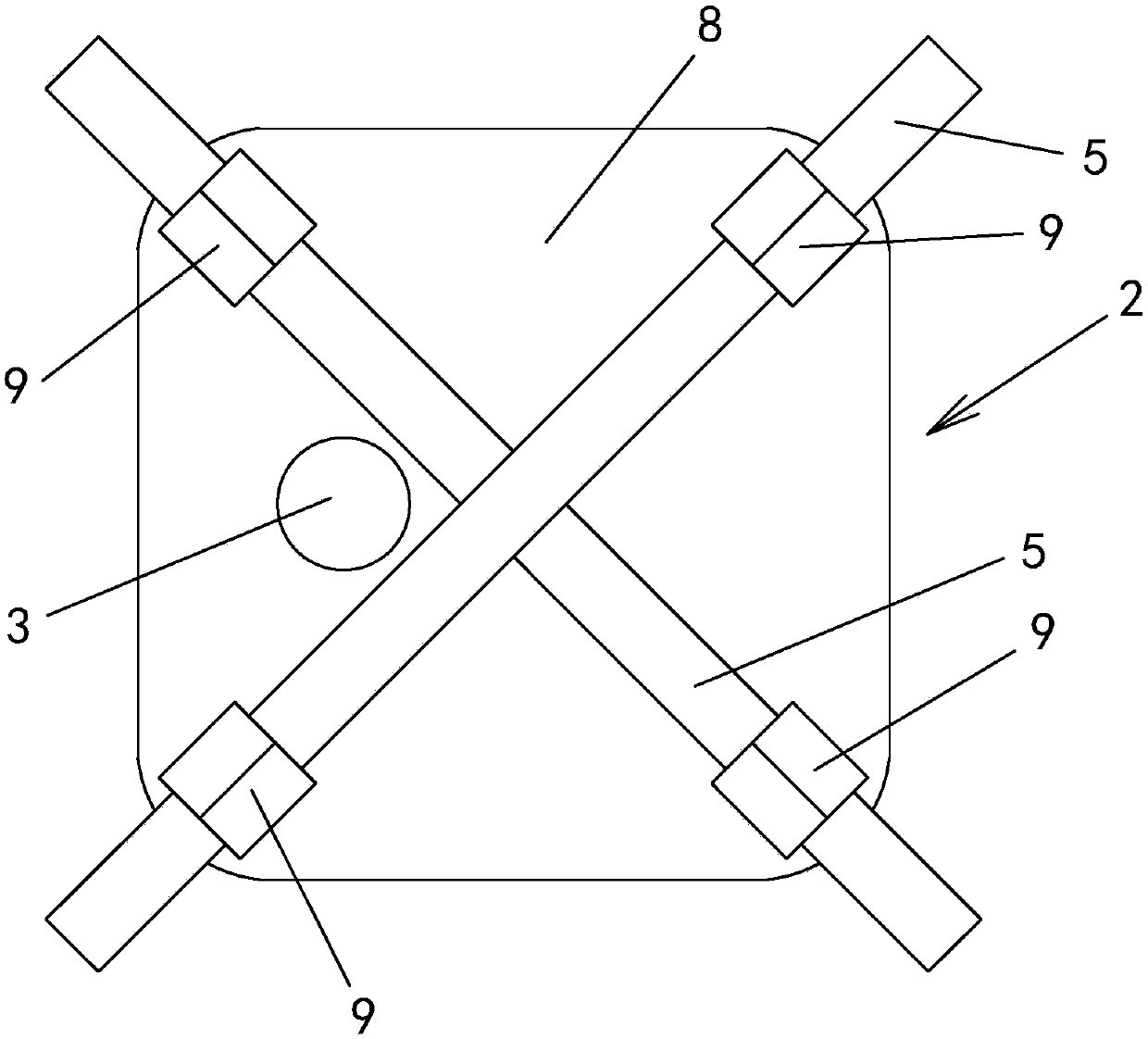

[0040] Example: see attached Figure 1~4 As shown, a height-adjustable high-strength steel bar support includes an upper positioning frame 1, a lower positioning frame 2 and a pillar 3; the upper positioning frame 1 is used for positioning the upper rib 4, and the lower positioning frame 2 is used for Locate the lower row of ribs 5, and the upper positioning frame 1 and the lower positioning frame 2 are all height-adjustably positioned on the pillar 3; through the height-adjustable design, the distance between the upper positioning frame 1 and the lower positioning frame 2 can be changed , and then change the spacing between the upper row of bars 4 and the lower row of bars 5, so that the steel bar bracket can adapt to different steel bar cover thickness requirements.

[0041] The upper positioning frame 1 includes a supporting plate 6, the plate body of the supporting plate 6 is arranged horizontally, and the circumference of the supporting plate 6 protrudes upwards with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com