Wastewater recovering system

A waste water recycling and sump technology, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage multi-stage treatment, etc., can solve the problems of many harmful substances, environmental pollution, large amount of sewage, etc., to protect the living environment , easy to use, the effect of purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

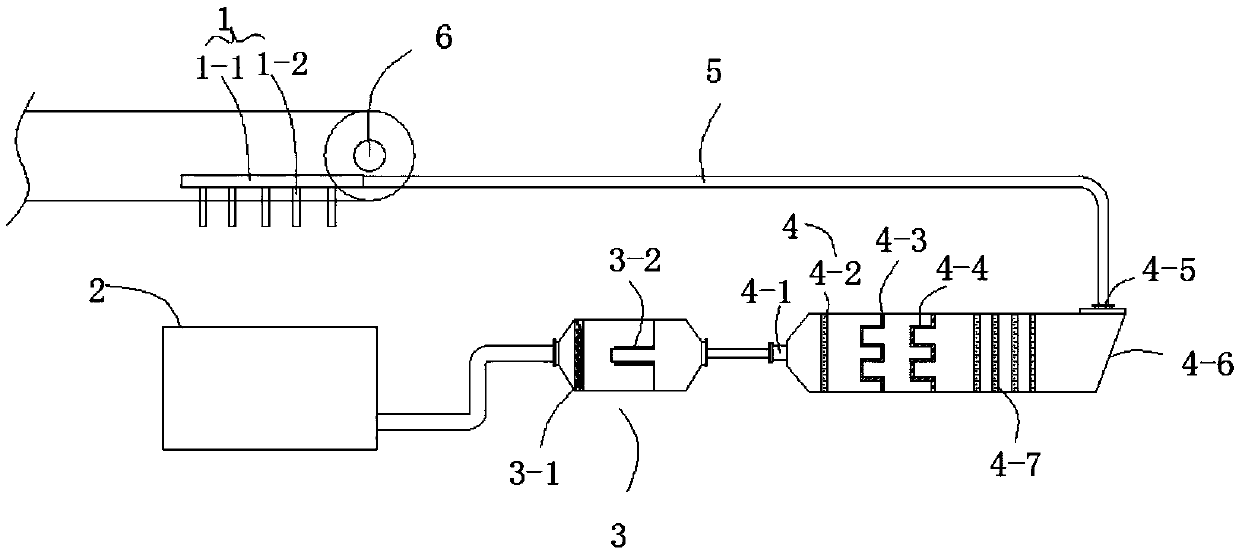

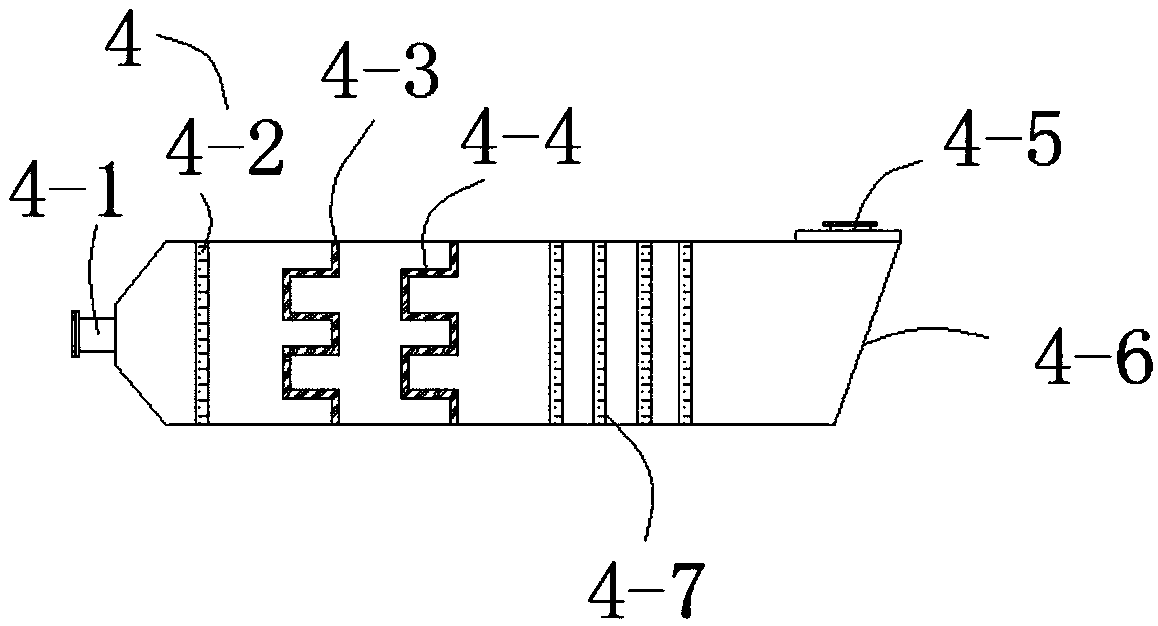

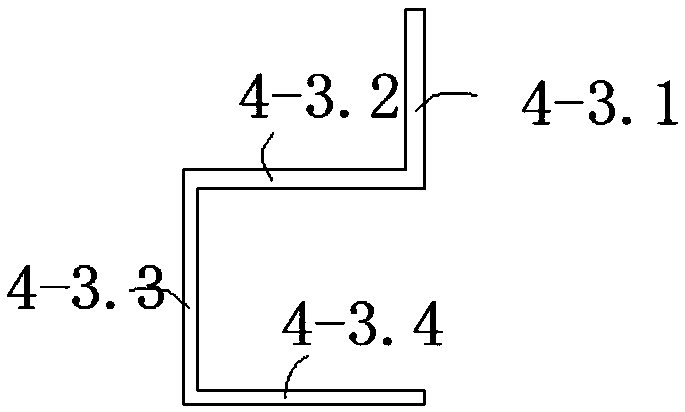

[0021] Such as Figures 1 to 2 As shown, this embodiment provides a waste water recovery system, including a sump 2, a filter assembly 4, and a spray assembly 1 connected sequentially through pipelines. The spray assembly 1 is arranged above the sump 2. It is characterized in that the sump 2 A flow regulating chamber 3 is connected between the filter assembly 4, the spray assembly 1 includes a main spray pipe 1-1 and a branch spray pipe 1-2 communicated with the main spray pipe 1-1, and the branch spray pipe 1-1 2 is provided with a plurality of atomizing nozzles, the filter assembly 4 includes a housing 4-6, and the decibels at both ends of the housing 4-6 are provided with a liquid inlet 4-1 and a liquid outlet 4-5, and the liquid outlet 4-5 The spray assembly 1 is connected to the recovery pipe 5, and the housing 4-6 is detachably provided with an activated carbon layer A4-2, an activated carbon layer B4-3, an activated carbon layer C4-4 and an activated carbon layer D4-7, ...

Embodiment 2

[0024] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0025] The flow regulating chamber 3 is provided with a flow regulating structure 3-1 and a primary filter 3-2, and the flow regulating structure 3-1 includes a connecting rod 3-1.2, a fixed frame 3-1.3 and a plurality of adjustable filter elements arranged up and down. Plate 3-1.1, the same end of each adjustable filter plate 3-1.1 is hinged on the connecting rod 3-1.2, and the other ends of all adjustable filter plates 3-1.1 except the uppermost adjustable filter plate 3-1.1 are connected On the fixed frame 3-1.3, the other end of the uppermost adjustable filter plate 3-1.1 is hinged on the inner wall of the flow regulating chamber 3, and the lower surface of the lowermost adjustable filter plate 3-1.1 is hinged with a telescopic cylinder 3-1.4 The telescopic shaft, the other end of the telescopic cylinder 3-1.4 is hinged at the bottom of the flow regulating cavity 3 .

[0026] Both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com