Anti-loosening and anti-abnormal noise structure for rear axle stabilizer bar

A stabilizer bar, anti-loosening technology, used in interconnection systems, vehicle components, transportation and packaging, etc., can solve problems such as corrosion and loss of torque at connecting parts, damage to rear axle contact surfaces, and reduce driving quality, to eliminate material creep. , The effect of ensuring that the axial force does not decline and improving the driving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

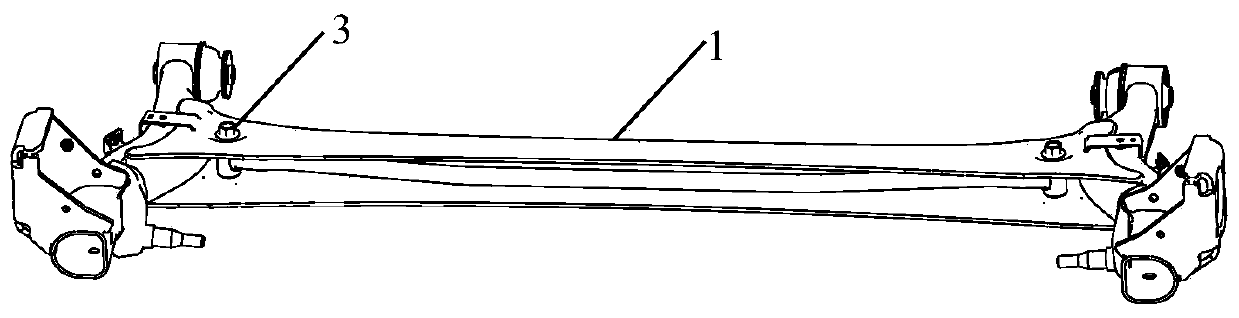

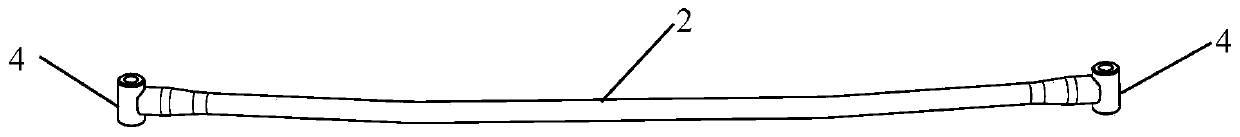

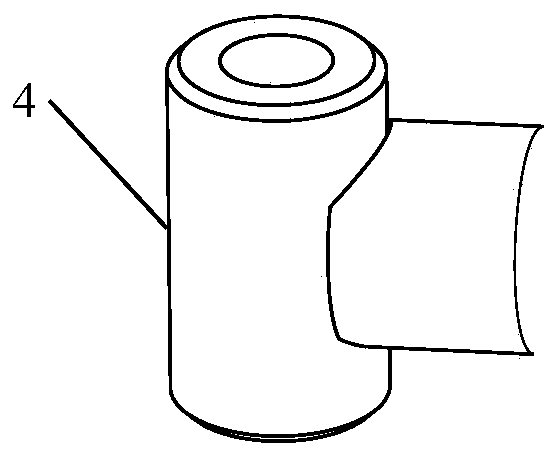

[0038] Such as figure 1 with figure 2 As shown, the rear axle stabilizer bar 2 in the prior art is generally connected to the rear axle through fasteners 3 . The fastening contact between the stabilizer bar sleeve 4 and the rear axle 1 is usually connected by two connection methods, one connection method is plane connection, such as image 3 As shown, once this kind of structure is loose, when passing a bumpy road or turning quickly, the line change will produce abnormal noise, causing great after-sales complaints; the other is a sawtooth surface connection, such as Figure 4 As shown, the sawtooth of this kind of structure will damage the contact surface of the rear axle 1 and cause corrosion when the car is running. Cause loose noise.

[0039] In view of the above problems, this embodiment provides a rear axle stabilizer bar anti-loosening and anti-abnormal noise structure, including a rear axle stabilizer bar 2, and the rear axle stabilizer bar 2 is fixed on the rear ax...

Embodiment 2

[0045] This embodiment provides a rear axle stabilizer bar anti-loosening and anti-abnormal noise structure, including a rear axle stabilizer bar 2, and the rear axle stabilizer bar 2 is fixed on the rear axle by fasteners 3, such as figure 1 with figure 2 shown. Both ends of the rear axle stabilizer bar 2 are respectively provided with a stabilizer bar sleeve 4, and the stabilizer bar sleeve 4 is welded to the surface of the rear axle stabilizer bar 2 along the welding seam 5, as Figure 5 shown. The material of the stabilizer sleeve 4 has a wide range of sources, low carbon steel and alloy steel can be used, and the cost is low.

[0046] Such as Figure 5 As shown, the stabilizer bar sleeve 4 has a tube top surface 6 and a tube bottom surface 7 , and the tube top surface 6 is the contact surface between the stabilizer bar sleeve 4 and the rear axle 1 . The cylinder top surface 6 is processed into a first circular ring plane 61 and a second circular ring plane 62 with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com