A liquid metal flexible shielding material and preparation method thereof

A technology of liquid metal and shielding materials, applied in the direction of metal layered products, chemical instruments and methods, protective equipment, etc., can solve the problems of poor stretchability and mechanical strength, environmental toxicity hazards, poor flexibility, etc., and achieve radiation absorption Good performance, high ultimate tensile stress, and high degree of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

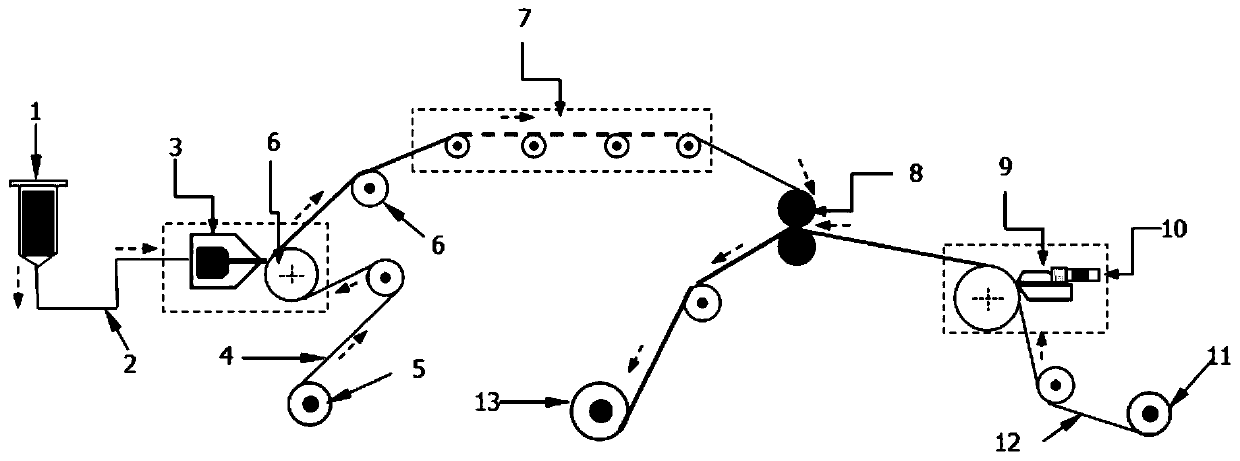

[0047] The invention also provides a method for preparing a liquid metal flexible shielding material, comprising: melting and coating the liquid metal on the surface of the substrate layer to form a liquid metal layer, and plating an anti-aging layer on the surface of the liquid metal layer by OSP technology.

[0048] In a preferred embodiment, the thickness of the liquid metal flexible shielding material is preferably 0.01-5 mm.

[0049] Wherein, forming the liquid metal layer by melting and coating the liquid metal on the surface of the substrate layer specifically includes:

[0050] Apply an adhesive layer on the surface of the substrate layer, melt and coat the liquid metal on the substrate to form a substrate containing the liquid metal layer, then use a pressure roller to combine the adhesive layer with the substrate containing the liquid metal layer, and remove the lining You get what you pay for.

[0051] Wherein, the material of the adhesive layer is preferably a the...

Embodiment 1

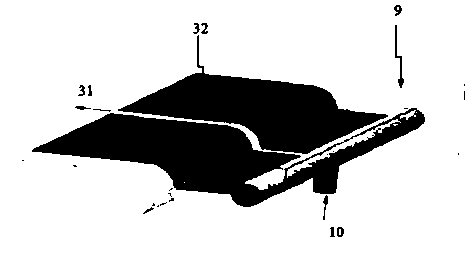

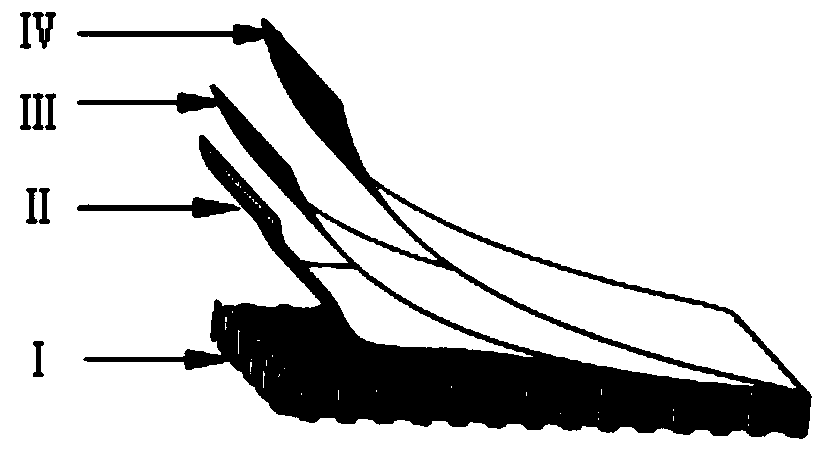

[0067] (1), the structure of the liquid metal flexible shielding material is as follows:

[0068]

[0069] The radiation shielding material of traditional lead-containing particle silica gel or rubber is thicker than 2mm;

[0070] (2), Material mechanical properties and 180Kev energy zone shielding performance data table:

[0071] performance content value Tensile strength (MPa) 19.20 Elongation at break (%) 300 Bending resistance (times) >1000 X-ray shielding rate (%) 95.2 Gamma ray shielding rate (%) 96.7 Neutron shielding rate (%) 96.9

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com