A kind of automatic ejector device with time delay function and mold having the same

An automatic ejection and functional technology, applied in electric vehicles, vehicle energy storage, transportation and packaging, etc., can solve problems such as long research and processing time, inconvenient assembly and replacement, large overall size of the mold, etc., to achieve no collision Hidden dangers of the mold, convenient assembly and replacement, and the effect of ensuring quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

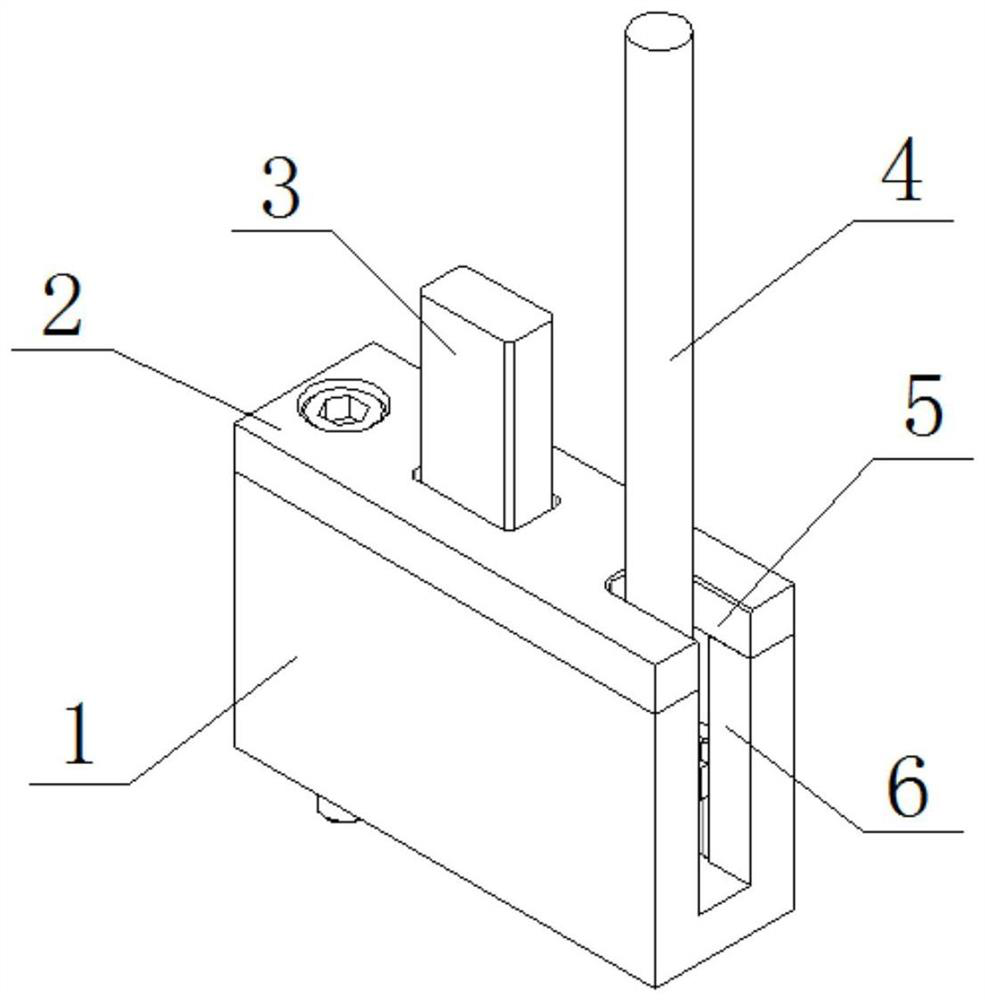

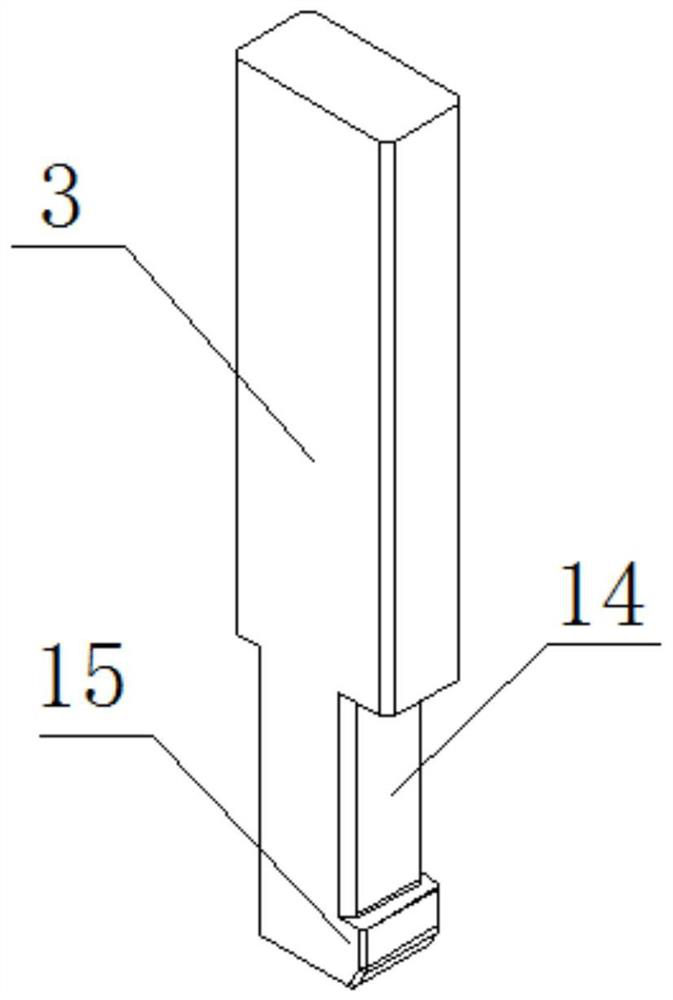

[0039] like Figure 1 to Figure 8 As shown, this embodiment provides an automatic ejection device with a delay function, including a base 1, an upper cover 2, a pressing block 3, a dial 8, a locking block 12 and an ejector 4, and the upper cover 2 is fixedly arranged on the On the base 1, the upper cover 2 is welded on the upper surface of the base 1, the base 1 is provided with a placement groove 10, the dial block 8 is set in the placement groove 10, the upper cover 2 is provided with a pressure block mounting hole 9, and the dial block 8 is provided with A pressure block guide hole 13 and a lock block guide hole 20 are provided, the lower end of the pressure block 3 is arranged through the pressure block guide hole 13, the upper end of the pressure block 3 is arranged through the pressure block installation hole 9, and the lock block 12 is arranged in the lock block guide hole 20, The pressure block guide hole 13 and the lock block guide hole 20 communicate with each other,...

Embodiment 2

[0051] like Figure 3 to Figure 10 As shown, this embodiment provides an automatic ejection device with a delay function, including a base 1, an upper cover 2, a pressing block 3, a dial 8, a locking block 12 and an ejector 4, and the upper cover 2 is fixedly arranged on the On the base 1, the upper cover 2 is welded on the upper surface of the base 1, the base 1 is provided with a placement groove 10, the dial block 8 is set in the placement groove 10, the upper cover 2 is provided with a pressure block mounting hole 9, and the dial block 8 is provided with A pressure block guide hole 13 and a lock block guide hole 20 are provided, the lower end of the pressure block 3 is arranged through the pressure block guide hole 13, the upper end of the pressure block 3 is arranged through the pressure block installation hole 9, and the lock block 12 is arranged in the lock block guide hole 20, The pressure block guide hole 13 and the lock block guide hole 20 communicate with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com