Driving system of self-walking cleaning vehicle for lifting equipment

A lifting equipment and drive system technology, applied to cranes, traveling mechanisms, trolley cranes, etc., can solve problems such as increasing exhaust gas emissions, and achieve the effects of reducing fuel use, improving cleaning operations, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

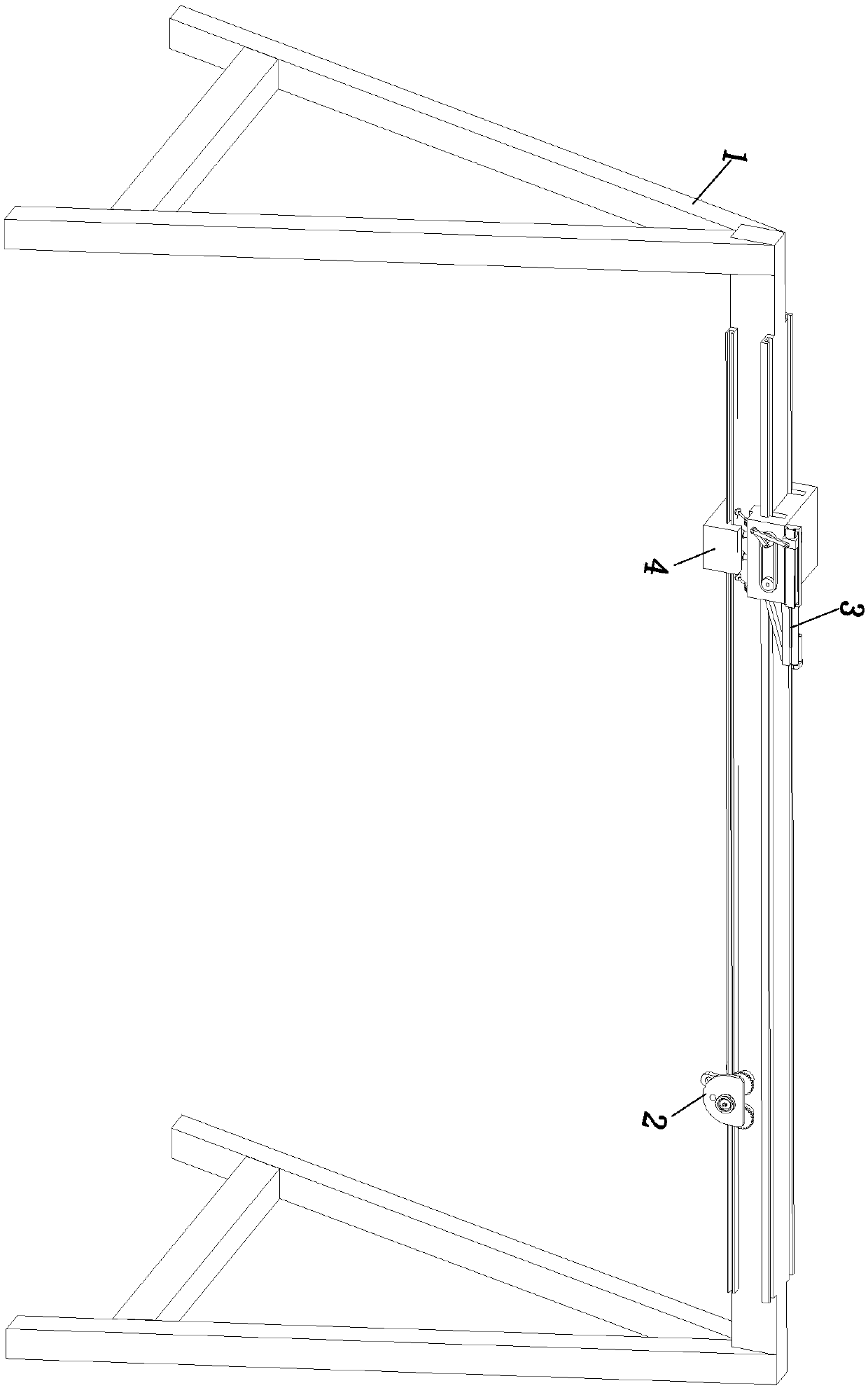

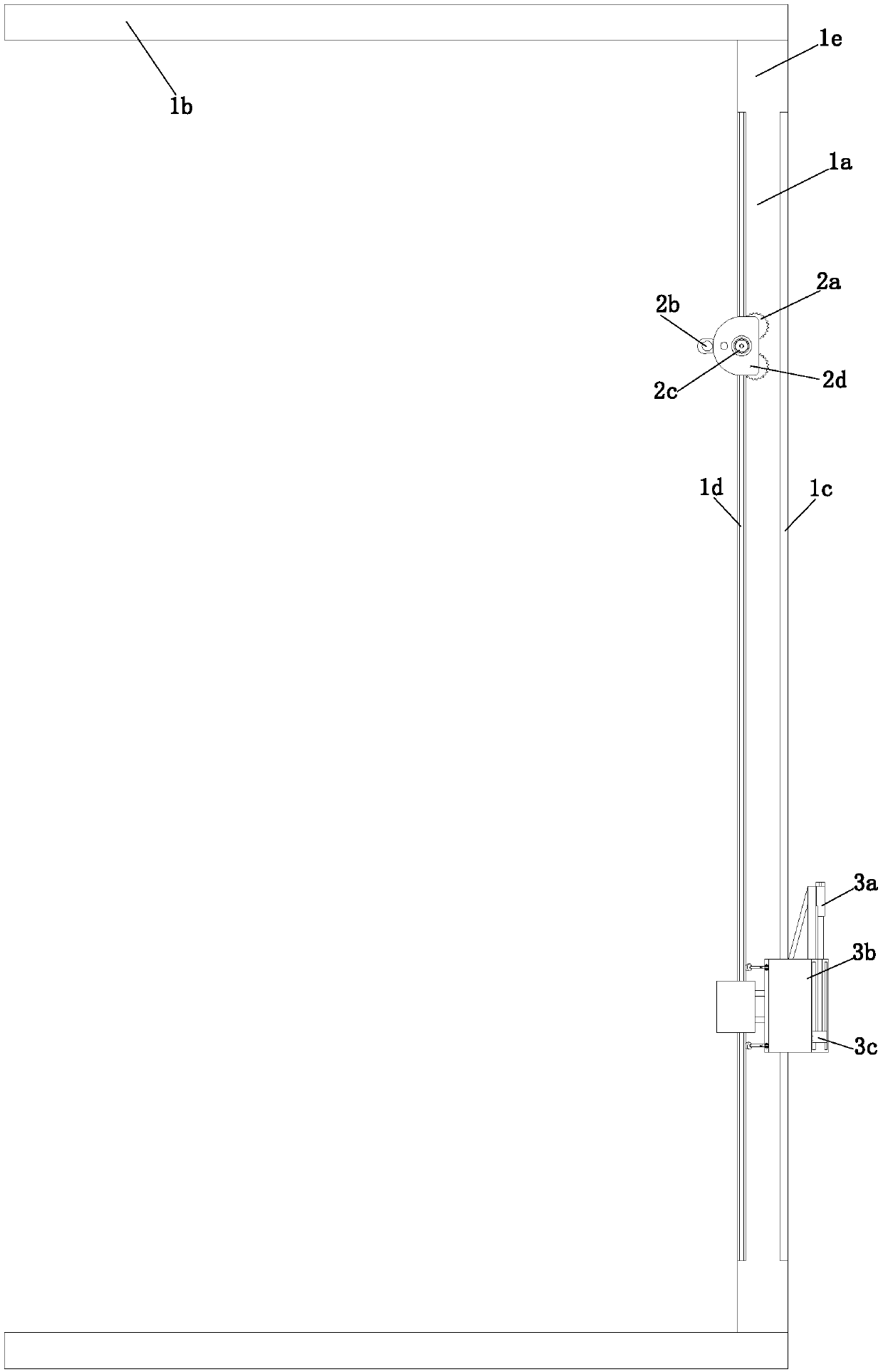

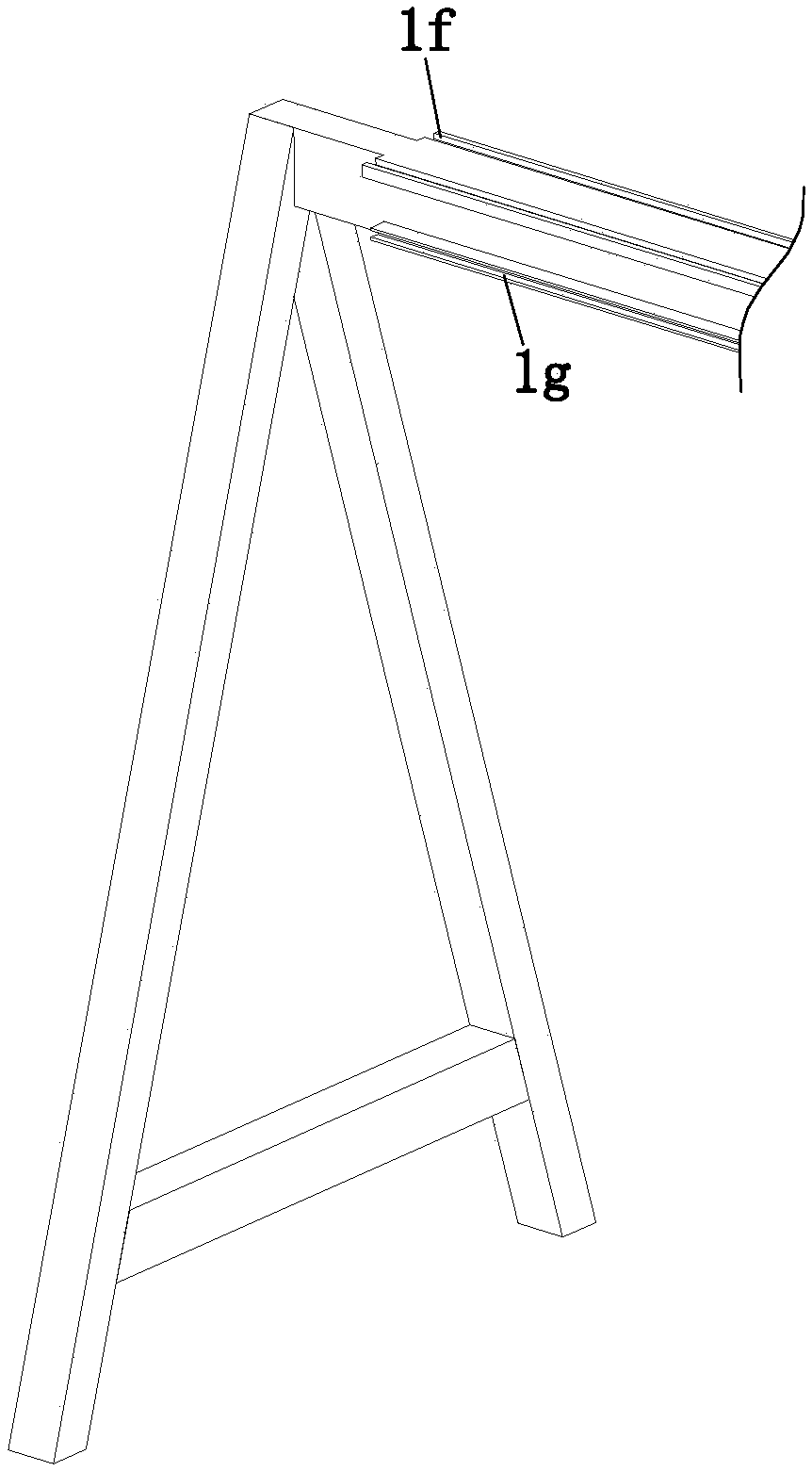

[0034] refer to Figure 1 to Figure 18 The shown lifting equipment with a dust cleaning device includes a gantry body 1, a load-bearing device 2, a driving device 3 and a cleaning device 4, and the load-bearing device 2, the driving device 3 and the cleaning device 4 are all movable Installed on the gantry body 1, the load-bearing device 2 includes a first moving mechanism 2a, a load-bearing mechanism 2b and a first driving mechanism 2c for driving the moving mechanism to move on the gantry body 1, and the cleaning device 4 includes a The cleaning base 4a that moves on the gantry body 1 and the cleaning mechanism 4b that is installed on the cleaning base 4a for cleaning the dust on the gantry body 1, the drive unit 3 includes a second drive mechanism 3a and The second moving mechanism 3b installed on the cleaning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com