Variable spraying method for plane polygon

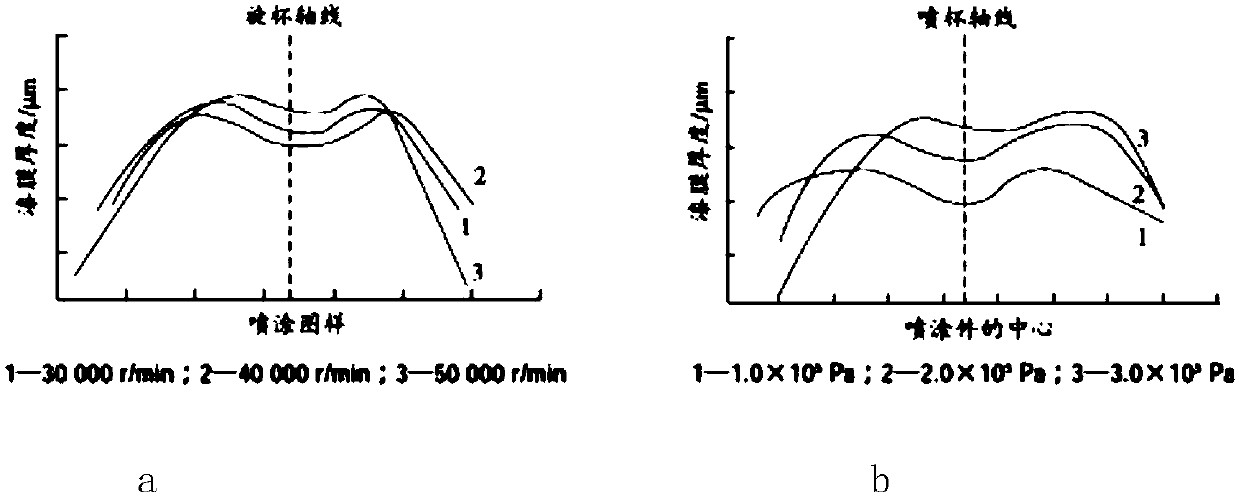

A polygonal and variable technology, applied in the field of off-line programming, can solve the problems of wasting paint, roughness, etc., and achieve the effects of strong practicability, saving paint amount, and optimizing spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

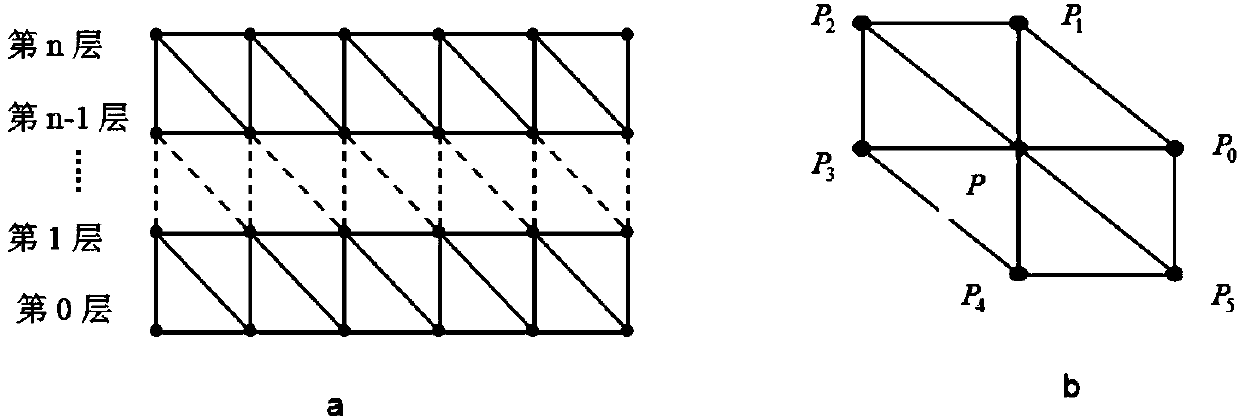

[0033] Step 1: Teach the tool TCP of the spraying robot, so that the tool can teach each vertex of the polygon with a suitable posture. The method of obtaining the pose of the spray gun is as follows:

[0034] 1) Mathematical model of spray gun trajectory

[0035] Assuming that the workpiece is fixed, the polygonal surface can be represented by the function z=h(x,y), where the mapping h:D→R, the definition domain So the function of the polygonal surface can be defined as:

[0036] S={(x,y,z)|z=h(x,y),(x,y)∈D} (1-1)

[0037] The pose is represented by the Cartesian coordinate system XYZ. Let the three-dimensional vector functions P(t) and O(t) represent the position and direction of the spray gun in the fixed Cartesian coordinate system respectively. The relationship between these two vectors and time t can be expressed as:

[0038] P(t)=[p x (t),p y (t),p z (t)] (1-2)

[0039] O(t)=[o x (t), o y (t), o z (t)] (1-3)

[0040] Among them, the vector p in formula (1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com