A method of arranging siu mai

A technology of siu mai and cups, which is applied in dough forming machinery or equipment, dough processing, baking, etc. It can solve the problems of low product qualification rate, siu mai extrusion deformation, and affecting the appearance of siu mai, achieving high safety , prevent breakage, and protect the appearance of the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

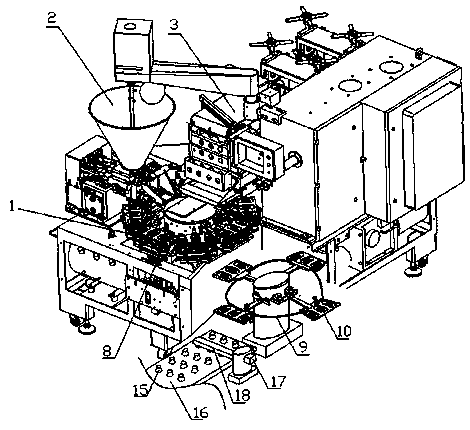

[0050] Such as Figures 1 to 13 Shown, a method for siu mai arranging, comprises the following steps:

[0051] In the first step, the first circular track 4 rotates to drive the forming mold to pass through the skin grafting station 5 and filling station 6 to make the siu mai 15 into shape, and the first circular track 4 continues to rotate to drive the forming mold to the blanking station 7 ;

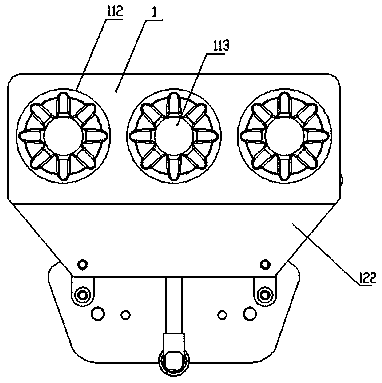

[0052] In the second step, the rack push rod 115 on the forming mold pushes the push block 122 inwardly, and the push block 122 pushes the left plate 117 and the right plate 118 and separates them, and the bottom of the through hole 113 is opened;

[0053] In the third step, at the same time as the second step, the motor 206 on the first opening and closing cup 8 drives the gear 207 to rotate clockwise, and the gear 207 drives the long rack 205 to move to the left until the baffle plate 202 blocks the bottom of the material receiving hole 201 ;

[0054] In the fourth step, the siu mai ...

Embodiment 2

[0064] Such as Figures 1 to 13 Shown, a kind of method for siu mai arranging, comprises the following steps:

[0065] In the first step, the first circular track 4 rotates to drive the forming mold to pass through the skin grafting station 5 and filling station 6 to make the siu mai 15 into shape, and the first circular track 4 continues to rotate to drive the forming mold to the blanking station 7 ;

[0066] In the second step, the rack push rod 116 on the forming mold pushes the push block 122 inwardly, and the push block 122 pushes the left plate 117 and the right plate 118 and separates them, and the bottom of the through hole 113 is opened;

[0067] In the third step, at the same time as the second step, the motor 206 on the first opening and closing cup 8 drives the gear 207 to rotate clockwise, and the gear 207 drives the long rack 205 to move to the left until the baffle plate 202 blocks the bottom of the material receiving hole 201 ;

[0068] In the fourth step, th...

Embodiment 3

[0080] Such as Figures 1 to 13 Shown, a kind of method for siu mai arranging, comprises the following steps:

[0081] In the first step, the first circular track 4 rotates to drive the forming mold to pass through the skin grafting station 5 and filling station 6 to make the siu mai 15 into shape, and the first circular track 4 continues to rotate to drive the forming mold to the blanking station 7 ;

[0082] In the second step, the rack push rod 116 on the forming mold pushes the push block 122 inwardly, and the push block 122 pushes the left plate 117 and the right plate 118 and separates them, and the bottom of the through hole 113 is opened;

[0083] In the third step, at the same time as the second step, the motor 206 on the first opening and closing cup 8 drives the gear 207 to rotate clockwise, and the gear 207 drives the long rack 205 to move to the left until the baffle plate 202 blocks the bottom of the material receiving hole 201 ;

[0084] In the fourth step, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com