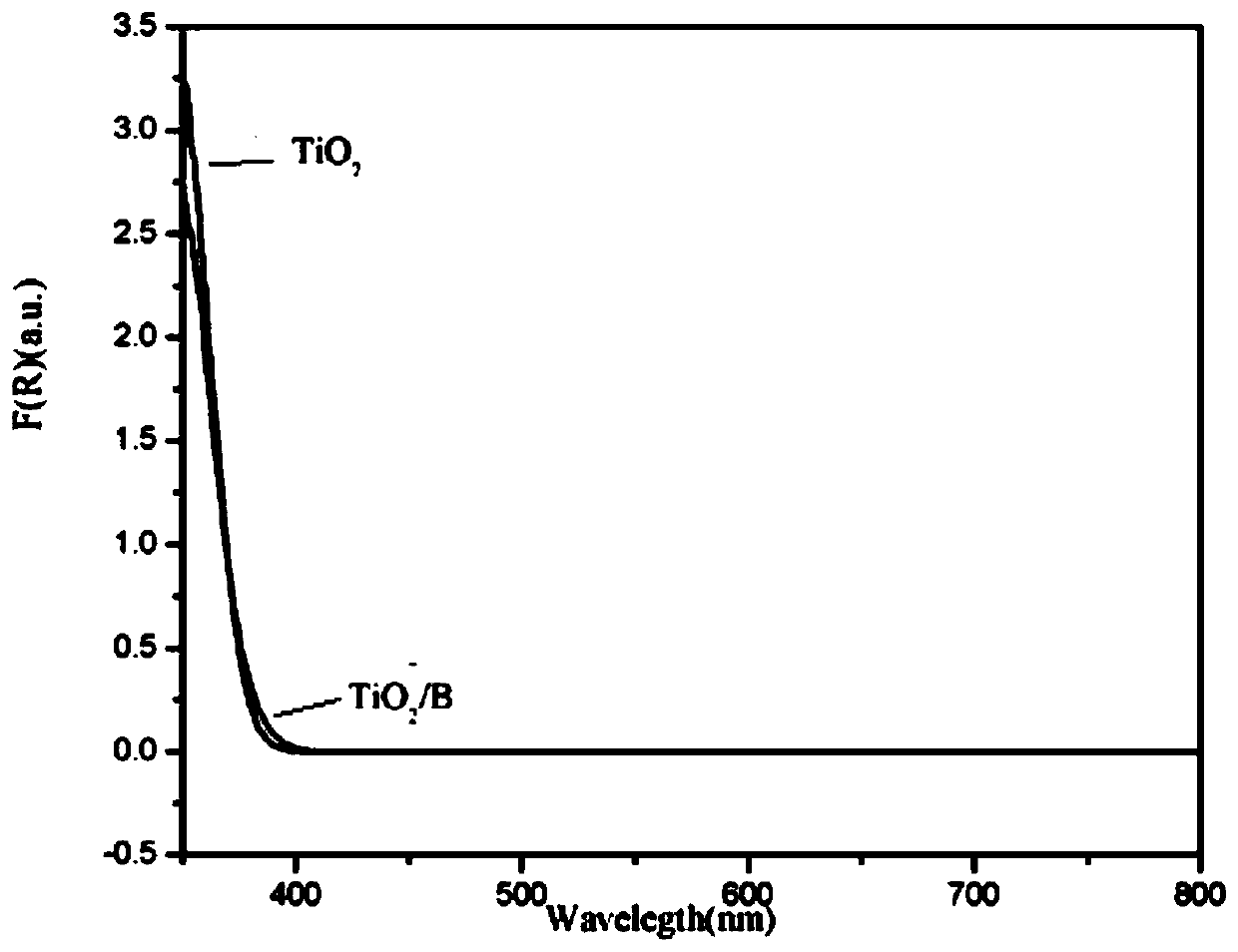

A boron-doped titanium dioxide photo-assisted gas sensor and its preparation method and application

A gas-sensing element and titanium dioxide technology, applied in the field of gas-sensing sensors, can solve the problems of low selectivity, flammability and explosion, poor stability, etc., and achieve the effects of simple preparation method, good gas-sensing response, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] TiO 2 and B / TiO 2 Preparation of gas sensor

[0026] Preparation of B / TiO 2 Material: take 1.24g of H 3 BO 3 In a 100ml beaker, add 50ml of deionized water to dissolve, add 7ml of isopropyl titanate dropwise under continuous stirring, stir at room temperature for 12h, bake at 100°C for 12h, and bake at 500°C for 1h.

[0027] Preparation of TiO 2 Materials: Take 50ml of deionized water in a 100ml beaker, add 7ml of isopropyl titanate dropwise under constant stirring, bake at 100°C for 12h, and bake at 500°C for 1h.

[0028] First use deionized water, ethanol, and ultrasonic for 20 minutes to wash the gold interdigitated electrode sheet, and dry it for later use.

[0029] Weigh 30mg of TiO 2 , B / TiO 2 Put the powder into two 1.5ml vials, add 1ml of ethylene glycol dropwise, ultrasonically disperse for 1 hour, use a pipette gun to pipette 50μL and drop it on the cleaned electrode sheet, and dry it at 80°C after it spreads evenly , and finally, place the electrode ...

Embodiment 2

[0039] A kind of preparation method of boron-doped titanium dioxide light-assisted gas sensor

[0040] 1) Under stirring conditions, the H 3 BO 3 The solution was added dropwise in isopropyl titanate, the H 3 BO 3 The ratio of isopropyl titanate to isopropyl titanate was 1 g: 6 mL, stirred at room temperature for 12 h and dried at 100 °C, and the obtained material was calcined at 500 °C to obtain B / TiO 2 powder;

[0041] 2) Use deionized water and ethanol to ultrasonically wash the gold interdigitated electrode sheet for 25 minutes, and dry it for later use;

[0042] 3) Weigh 30mg B / TiO 2 Put the powder in a medicine bottle, and drop 1 mL of ethylene glycol into the ultrasonic dispersion to obtain the gas-sensitive material, then use a pipette gun to pipette 50 μL of the gas-sensitive material and drop it on the surface of the gold finger electrode, wait for it to spread evenly, and place it at 80°C Drying, finally, place the gold interdigitated electrode sheet in a muff...

Embodiment 3

[0044] A kind of preparation method of boron-doped titanium dioxide light-assisted gas sensor

[0045] 1) Under stirring conditions, the H 3 BO 3 The solution was added dropwise in isopropyl titanate, the H 3 BO 3 The ratio of isopropyl titanate to isopropyl titanate is 1 g: 5 mL, stirred at room temperature for 8 h and then dried at 110 °C, and the obtained material was calcined at 400 °C to obtain B / TiO 2 powder;

[0046] 2) Use deionized water and ethanol to ultrasonically wash the gold interdigitated electrode sheet for 20 minutes, and dry it for later use;

[0047] 3) Weigh 30mg B / TiO 2 Put the powder into a medicine bottle, and drop 1 mL of ethylene glycol into the ultrasonic dispersion to obtain the gas-sensitive material, then use a pipette gun to pipette 50 μL of the gas-sensitive material and drop it on the surface of the gold finger electrode, wait for it to spread evenly, and store it at 70°C Drying, finally, place the gold interdigitated electrode sheet in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com