Method and system for controlling water injection

A water injection and collection system technology, applied in electrical control, charging system, engine control, etc., can solve problems such as increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

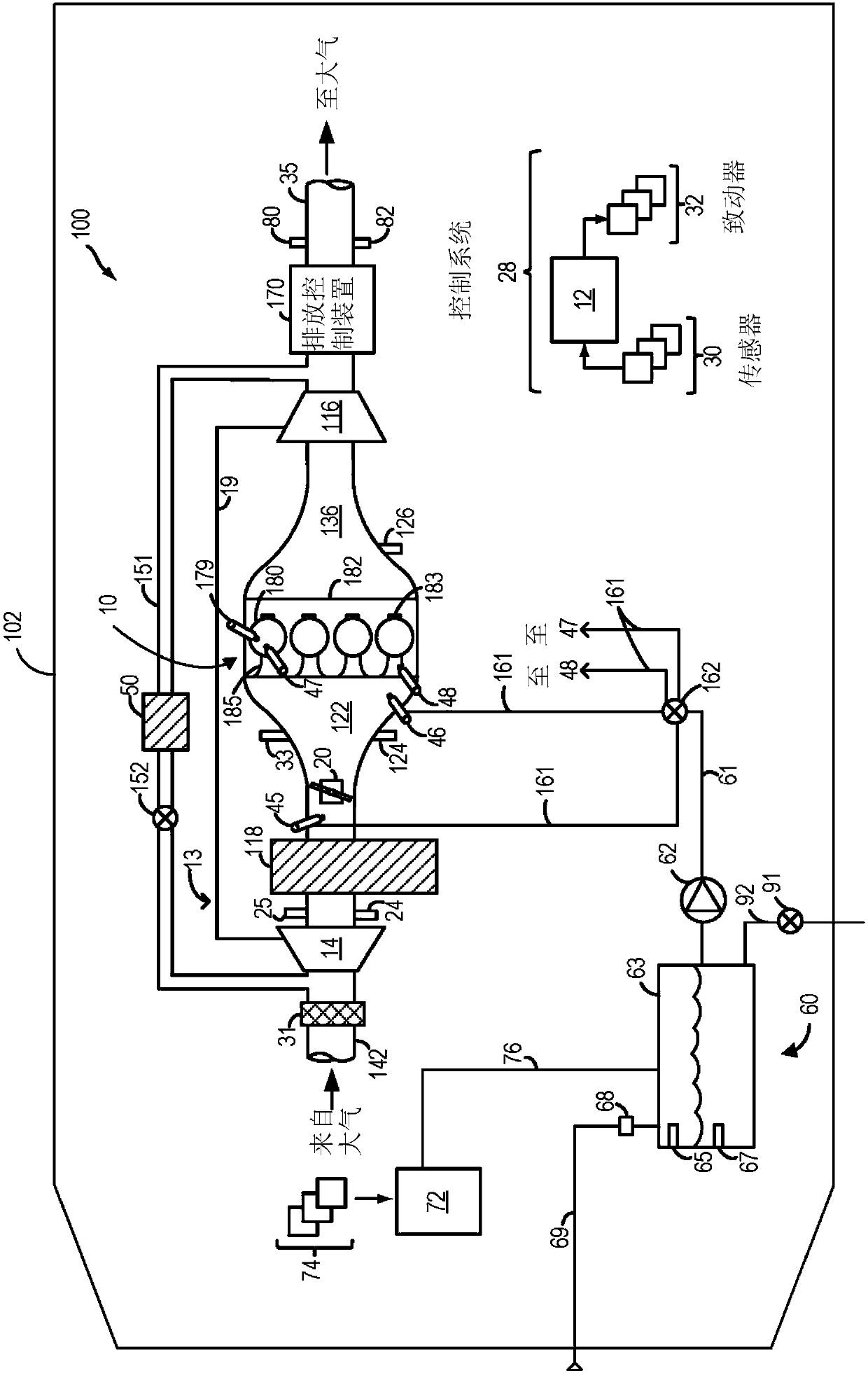

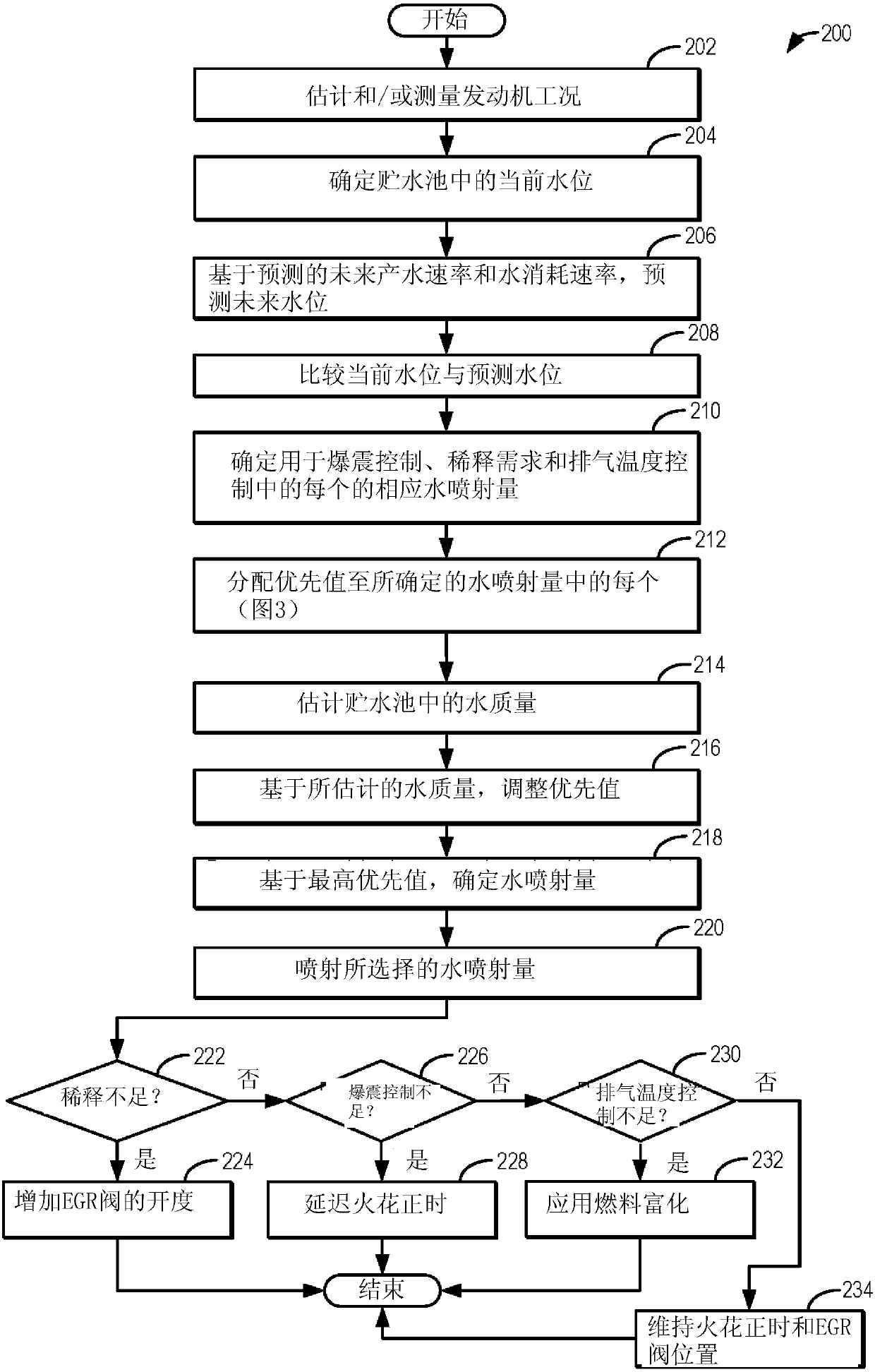

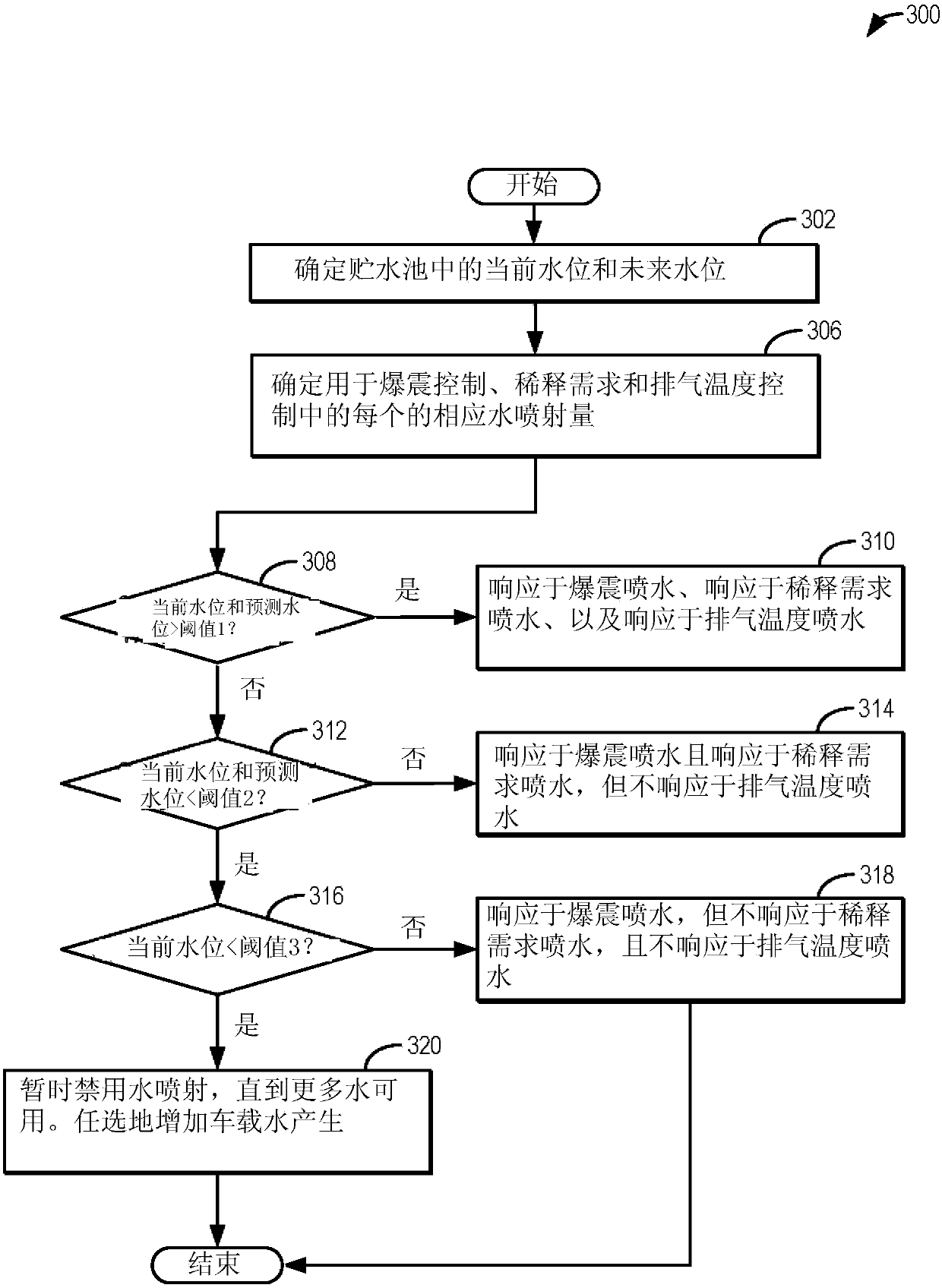

[0013] The following description relates to systems and methods for utilizing the benefits of injecting water into an engine from a water injection system coupled to a vehicle engine, as referenced figure 1 the vehicle described. The controller can be configured to execute control routines such as figure 2 An example routine for assigning priority values to different water injection quantities for knock control, dilution control, and exhaust temperature control based on water availability, and then selecting the injection quantity with the highest priority value for delivery. The controller can also be configured to execute control routines such as image 3 An example routine to vary the water injection sequence for knock control, dilution control, and exhaust temperature control based on water availability. Example Water Jet Adjustment Reference Figure 4 describe. In this way, the fuel economy benefits of water injection can be exploited (even when the water supply is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com