Vibrating filtering mechanism

A technology of filter mechanism and vibration mechanism, which is applied in the field of papermaking, and can solve problems such as easy damage and heavy load of the filter screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

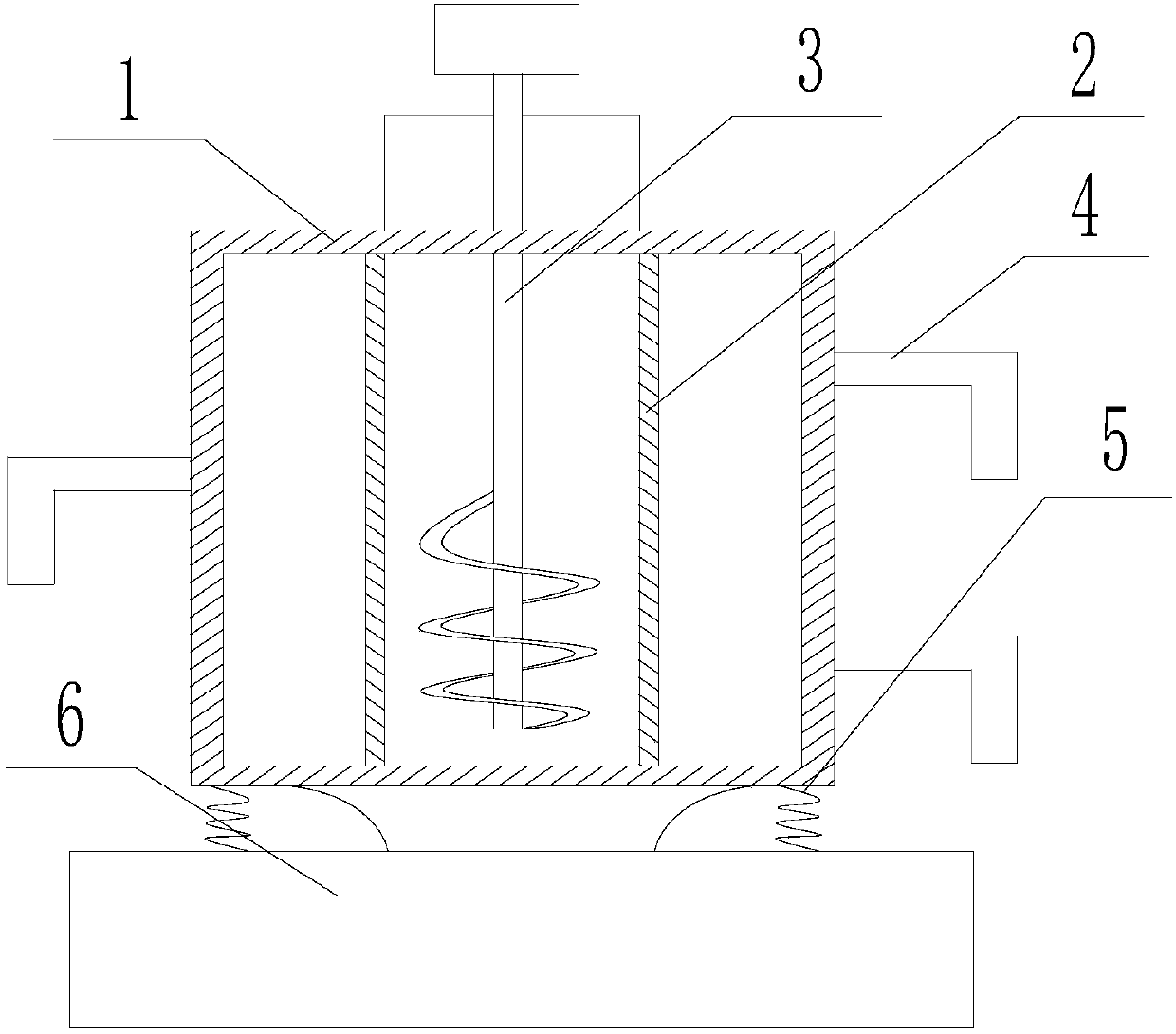

[0030] Such as figure 1 As shown, a vibrating filter mechanism includes a housing 1, and a cylindrical filter 2 is arranged in the housing 1. One end of the cylindrical filter 2 is in contact with the housing 1, and the other end protrudes from the housing. 1 top, the outer wall of the housing 1 is provided with three drain pipes 4 from top to bottom, and the lower part of the housing 1 is provided with a protective cover 6, and a reciprocating vibration mechanism is arranged inside the protective cover 6, so The housing 1 is connected to a compound vibration mechanism; the compound vibration mechanism is a crank connecting rod.

Embodiment 2

[0032] Such as figure 1 As shown, the cylindrical filter 2 is also provided with a stirring device 3; the stirring device 3 includes a rotating shaft and a bolt blade arranged on the rotating shaft; the cylindrical filter 2 includes 2 layers of annular filter screens, the inner layer The filter holes of the filter screen are larger than the filter holes of the outer filter screen; a shock absorbing mechanism 5 is arranged between the housing 1 and the protective cover 6; the shock absorbing mechanism 5 is a spring shock absorbing seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com