Aluminum cell with pre-baked anode

A technology of aluminum electrolytic cells and prebaked anodes, applied in the field of electrolytic aluminum, to achieve the effects of improving current efficiency, simple structure, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

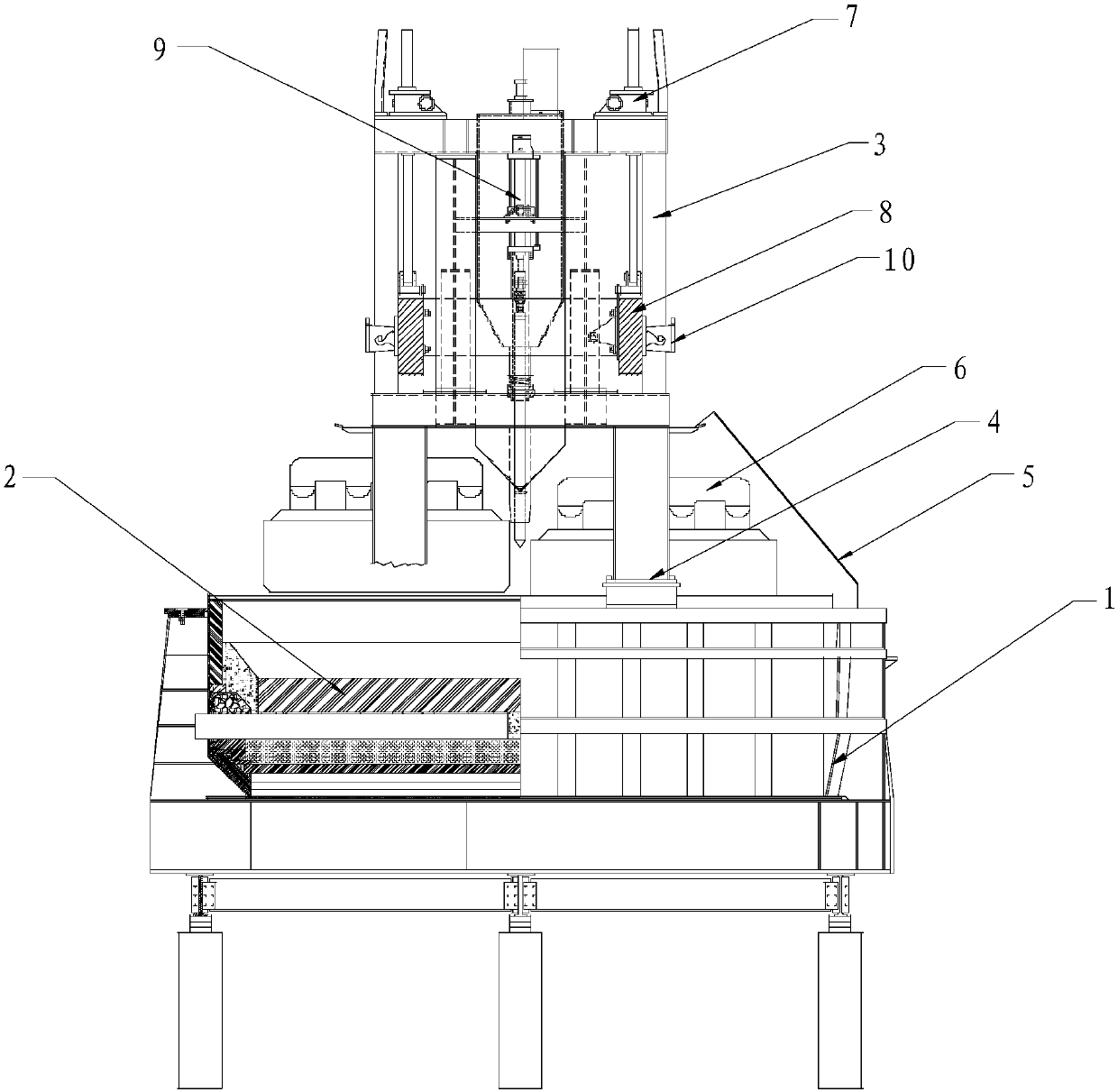

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] like figure 1 As shown, a prebaked anode aluminum electrolytic cell includes a tank shell body 1 with a hollow interior and an open upper end, a lining 2, a frame 3, a column 4, a sealing cover plate 5, a pair of anode carbon block groups 6, a pair of An anode lifting device 7, a pair of anode busbars 8, and a shell-breaking and unloading system 9, the inner lining 2 is set in the tank shell main body 1; the frame 3 is vertically set in the tank through the column 4 On the shell main body 1; the sealing cover plate 5 is closed on the opening; a pair of the anode carbon block groups 6 are arranged side by side at the opening of the tank shell main body 1; a pair of the anode lifting devices 7 It is arranged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com