A single-cavity molding twice-sealing mechanism of an injection mold

An injection mold and sealing technology, which is applied in the field of single-cavity molding secondary sealing mechanism, can solve the problems of high cost and complex structure, and achieve the effects of simple processing, simplified structure, and reduced mold manufacturing cost and injection molding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

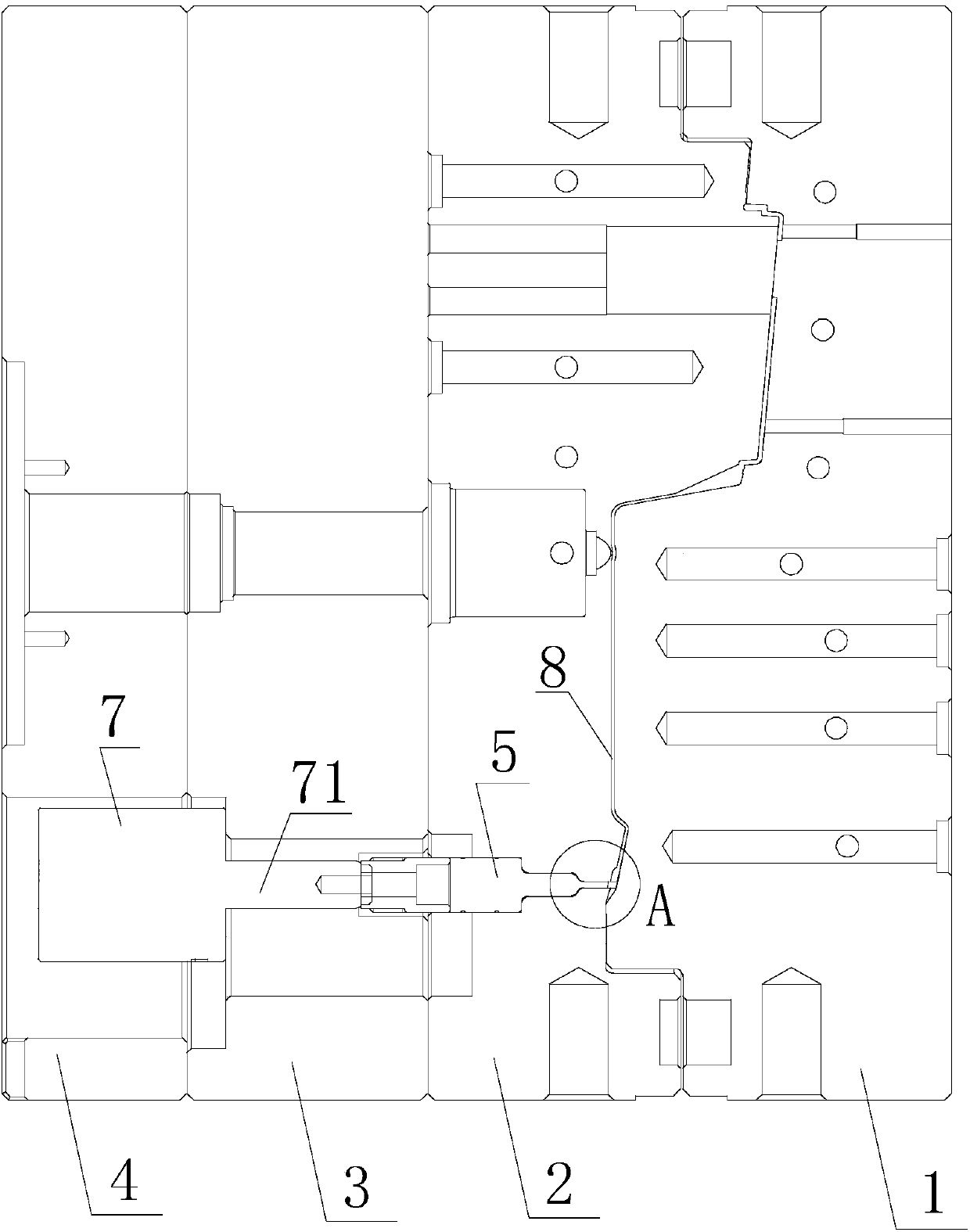

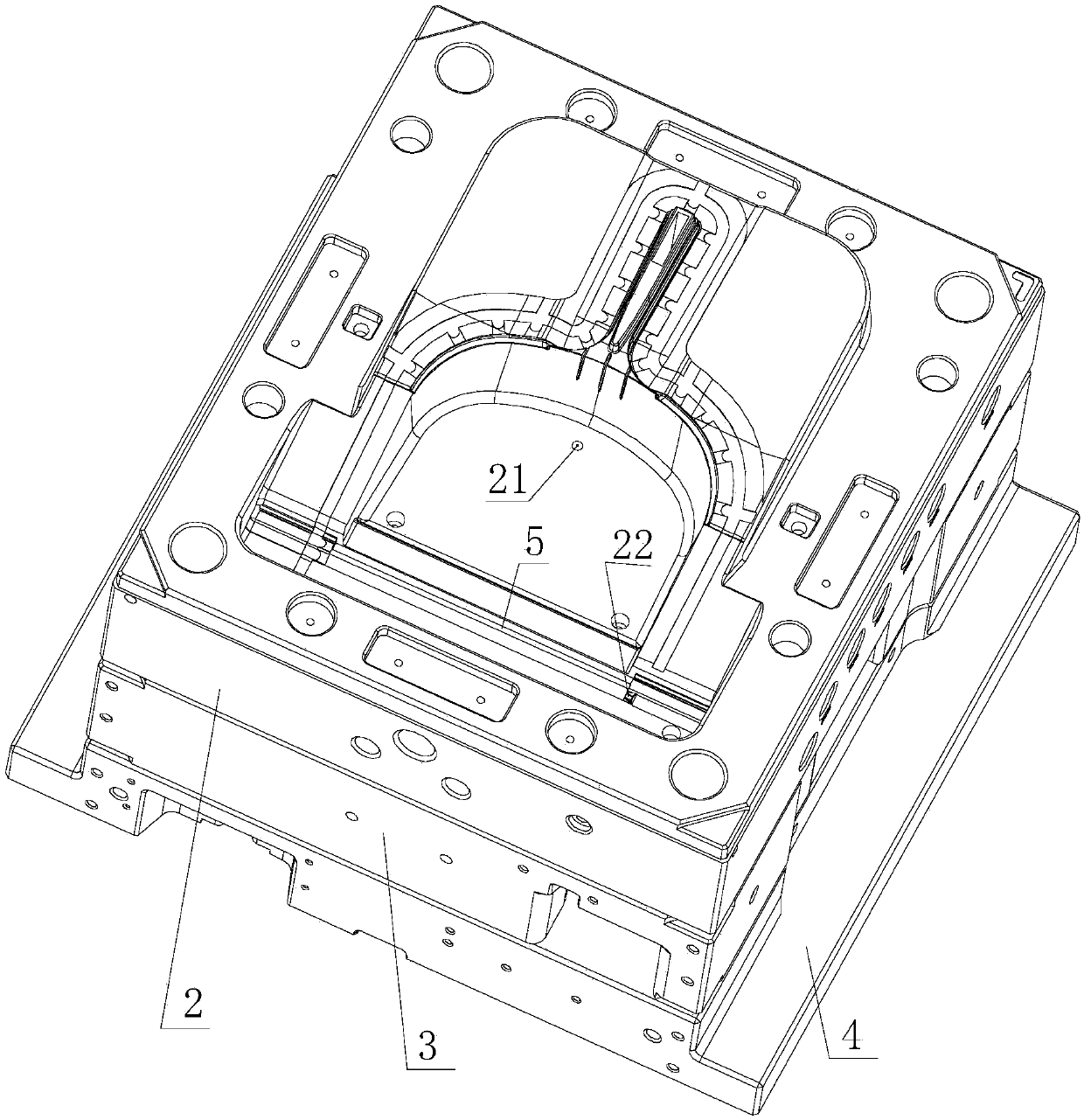

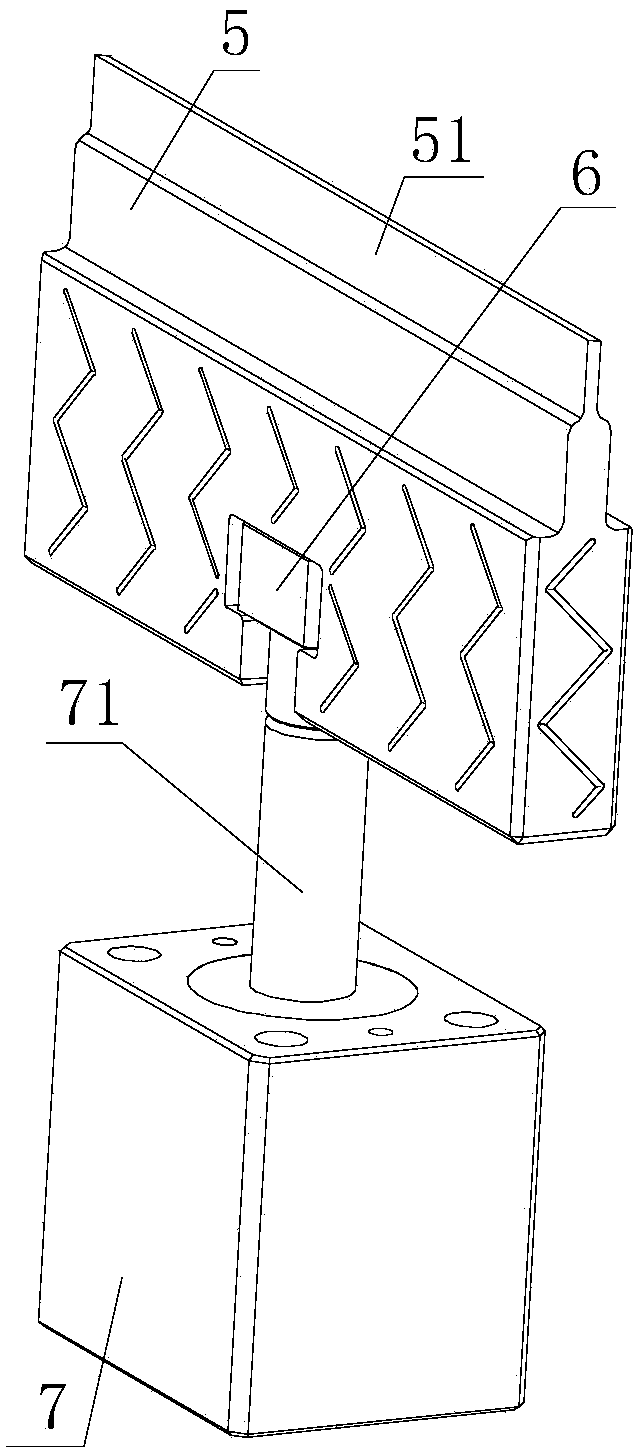

[0012] The present invention will be further described below in combination with the accompanying drawings and specific embodiments. Such as Figure 1-4 As shown, the single-cavity molding secondary sealing mechanism of the injection mold includes the upper press plate 4 of the injection molding machine, the hot runner plate 3 and the movable mold 1 and the fixed mold 2. The difference between the movable mold 1 and the fixed mold 2 is The mold cavity 8 is formed after the molds are closed, and the upper press plate 4, the hot runner plate 3 and the fixed mold 2 are also provided with a sealing core pulling mechanism.

[0013] The sealing and core-pulling mechanism includes a sealing and core-pulling slider 5, and the sealing and core-pulling slider 5 is connected to the piston rod 71 of the oil cylinder 7 through the oil cylinder connection block 6, and the oil cylinder 7 is installed on the upper press plate 4 Among them, a chute is formed in the hot runner plate 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com